Water resource management has become an important issue in recent years. On the one hand, it is getting more difficult than ever to predict the world’s annual rainfall; on the other hand, droughts are more unanticipated and may last for longer periods of time.

Today’s water resource managers must protect water resources and also prevent water leakage and contamination during delivery. This task is complicated by the fact that most water distribution infrastructures, which include pipelines and pumps, are located in isolated areas where wired communication devices are not available. Consequently they must rely on radio communications.

In this type of application, operators generally use remote terminal units (RTUs) to log data in local storage devices and then collect the data site by site. However, since in this case data is not transmitted in real-time, implementing video surveillance applications can be difficult.

As a result, managers are turning to cellular communications, a solution that features easy deployment, requires no site visits, and is suitable for video surveillance applications. With wireless and IP-based cellular communications, operators can easily install cellular modems, data loggers, I/O controllers and surveillance cameras at remote sites, and then manage the data from a central location. Because of these advantages, cellular communications is quickly replacing radio communications.

Challenges associated with deploying cellular communications

The first step is to choose the most appropriate cellular RTU solution, with selection criteria including price, hardware specifications and software functionality. However, easy deployment and maintenance, which are often overlooked, should also be considered since such challenges may require a lot of money and effort after installation.

Static Public IP:

For most cellular solutions, both the cellular modems at the remote sites and the scada server at the central site should be assigned static public IPs in order to establish bi-directional communications. However, cellular network carriers charge higher monthly fees for static public IPs and, since cellular fees are charged monthly, budget could be an issue. For this reason, managers may decide to shut down some remote sites.

Data consistency

Cellular communications helps users collect data logs from remote sites without needing to make site visits. During data transmission, it is challenging to ensure data consistency through cellular communications, given that signal quality and downtime may vary by location. An ideal data- logger should be able to re-transmit data logs after cellular reconnection, while avoiding transmitting duplicated data so as to reduce data transmission cost.

Hodgepodge device management

Some cellular solutions on the market use a hodgepodge of devices, including DTUs (data transfer units), data-loggers, I/O controllers, and video servers. Whether the devices are from the same vendor or not, system integrators (SIs) must make sure the devices are compatible and properly configured.

In such cases, troubleshooting can cause a lot of hassles for the following reasons. First of all, it can take quite a bit of time for system integrators to learn new protocols or functions supported by unfamiliar devices. Secondly, it can be difficult to locate which device is causing problems when an error occurs.

Moreover, system integrators may have problems finding qualified devices that support wide operating temperatures. Devices installed in harsh, wide temperature environments should at least support an operating temperature range from -20 to 70°C.

Moxa’s ioLogik W5300 cellular RTU controllers

With benefits such as cost efficiency, easy deployment, and trouble-free maintenance, Moxa’s ioLogik W5300 cellular RTU controllers have been used in many water and wastewater applications, such as pipeline monitoring and automated operations at lift or pump stations.

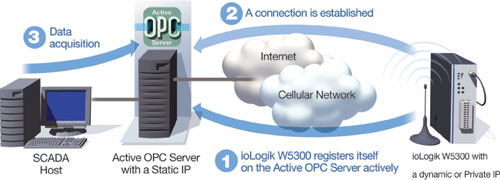

Dynamic Private IPs with Active OPC

Most cellular solutions require static public IPs, which can be extremely expensive, to allow the central site to query the data-loggers at any time. Moxa’s ioLogik W5300 series and patented Active OPC software allow users to subscribe to a dynamic private IP data plan for the RTUs. The ioLogik W5300 can automatically establish communications with the Active OPC Server using a fixed IP, and the Active OPC Server will receive and register the ioLogik W5300’s IP address and receive or record tag updates accordingly. ioLogik W5300 RTUs are very easy and cost effective to deploy and manage in a dynamic private IP environment (Figure 1).

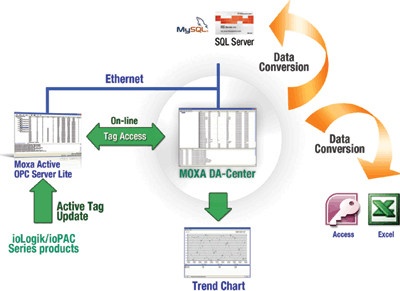

Data consistency with DA-Center

Collecting data logs over the air from a central site, without needing to visit remote sites, is one of the benefits of using cellular RTUs. In an ideal operation, the cellular RTUs should be able to retransmit non-duplicated data logs after cellular reconnection. With Moxa’s DA-Center, this task is much easier. The DA-Center provides a standard OPC interface that interacts with Active OPC Server for real-time data collection. After each cellular connection, the DA-Center will compare the historical data and the real-time data, and then complement the missing data by asking the ioLogik W5300 RTUs to re-transmit non-duplicated data logs into the dataset.

In addition, the DA-Center is able to convert this dataset into a tabular format for exporting the log files to a database or spreadsheets. Figure 2 shows the architecture of the DA-Center solution.

All-in-one Solution: cellular modem, data-logger and I/O controller

In order to reduce the amount of effort required to integrate devices from multiple vendors, the ioLogik W5300 RTU combines a cellular modem, a data-logger and an I/O controller in one compact box. If more I/O devices are required, the ioLogik W5300 RTU’s I/O channels can be expanded by connecting it to the ioLogik E1200. If a video server is required, the ioLogik W5300 RTU can be integrated with Moxa’s VPort 461 products. In addition, all products from the ioLogik W5300 series and ioLogik E1200 series, plus the VPort 461, support a wide operating temperature range for use in harsh environments.

Since many water resource managers are now looking for cellular RTU solutions to replace radio communications, knowing how to select the best cellular RTU is extremely important. The major concerns that managers must consider are deployment effort and maintenance costs. A well-designed cellular RTU delivers reliability, compatibility and integration solutions for a wide range of water and wastewater applications. Using dynamic private IPs and achieving data consistency reduces the cost and effort for both deployment and maintenance.

Moxa’s ioLogik W5300 RTUs are an ideal solution for water and wastewater applications, they have been selected by many water resource managers for monitoring applications at pipelines, lift stations and pump houses. These all-in-one solutions make the most out of cellular connectivity and save time, effort, and cost for both deployment and maintenance. As an added bonus, Moxa engineers are available for pre-sales consultations and after sales support.

For more information contact Rob Wright, RJ Connect, +27 (0)11 781 0777, [email protected], www.rjconnect.co.za

| Tel: | +27 11 781 0777 |

| Email: | [email protected] |

| www: | www.rjconnect.co.za |

| Articles: | More information and articles about RJ Connect |

© Technews Publishing (Pty) Ltd | All Rights Reserved