Energy management at the enterprise level is not only the responsibility of plant managers and engineers; it has now become the responsibility of corporate management as well. All departments within a company consume energy and add cost to a product or service, so everyone must be involved in developing and maintaining an energy management strategy that can be implemented to benefit the entire organisation’s bottom line and to accurately allocate costs where they were generated.

Energy management at the enterprise level is not only the responsibility of plant managers and engineers; it has now become the responsibility of corporate management as well. All departments within a company consume energy and add cost to a product or service, so everyone must be involved in developing and maintaining an energy management strategy that can be implemented to benefit the entire organisation’s bottom line and to accurately allocate costs where they were generated.

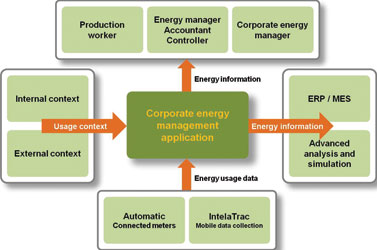

Collecting data from meters is easy. Using meter data for business decisions is not. What is needed is a corporate energy management application that transforms energy data into the information energy managers need and which addresses real-time management of energy usage in an operation. This information becomes essential for energy consumption awareness and cost reduction.

Energy management is a continuous improvement activity. Achieving and sustaining improvements in energy efficiency require reliable, real-time and contextualised information that the entire organisation can use to prove that new equipment and procedures have a positive impact and continue to deliver results.

When deviations to plan occur, the contextualised information enables their root-cause to be determined. Once the procedural or equipment changes are made, the application is used to make sure the correction was effective and sustained. An example of non-contextualised information could be: packing line 2 tripped at 10H17. Adding context makes all the difference: packing line 2 tripped at 10H17 on changeover from product A to product B and when packing line 3 was being started for product C.

Energy costing of operations

Do you know the energy cost to make your products or produce your service? Clean your equipment? Heat and cool the facility? Does one product incur higher energy cost than another? Is shift 1 more energy efficient than shift 2?

To answer these questions, it stands to reason that any corporate energy management application must allow you to define energy usage in your terms. Energy events enable the capturing of combined energy usage for any fixed or variable period of time. Examples are:

* Production order, batch, lot.

* Unit operation, phase, segment.

* Occupancy, hot days, cool days.

* Demand response episode.

* High flow condition.

* Equipment state (start-up, idle, in production).

If you are a financial controller or planner, you should have the information needed to manage your energy as the variable cost it is – today and in the future (Figure 2). You should be able to manage energy as you do labour and materials and as such, energy costs should form part of the bill of materials for products and should be part of your variance reporting process. In other words, to reflect reality it is important to measure cost rather than consumption.

The cornerstone for corporate energy management initiatives

A vast array of equipment, techniques and consulting is available to corporations and agencies that embark on an energy management initiative. Governments and industries are adopting new standards to define and execute the programmes and the established standards follow in the steps of continuous improvement programmes for quality, safety and operational effectiveness. The corporate energy management application will be the one place where all members of the team come to determine if equipment, techniques and consulting are effective and sustainable. The real-time and historical information provided will quickly become part of your organisation’s operational culture as individuals can visibly see their contribution towards helping the company achieve its energy usage objectives.

Smart meters – do not replace, capitalise

Energy providers world-wide are installing ‘smart meters’ on homes, businesses and industrial sites to enable automated meter reading, time-of-use price contracts and load conditions for grid operations. But that means replacing costly hardware with even more costly hardware – so why not add this functionality (and much more) to your existing metering hardware with a corporate energy management application that, thanks to its object-oriented technology, will turn each meter into a cost computer, applying real-time prices to energy usage and providing this information to operations, managers and cost accounting.

Smart grid ready

Industrial, commercial and infrastructure facilities are constantly faced with challenges when managing the use of energy to produce goods and services. In times of high energy costs, the energy component of production cost is critical to the business. In the future, these facilities will be nodes on an intelligent energy supply chain network, also known as a smart grid.

A smart grid delivers electricity from suppliers to consumers using two-way digital technology to control appliances at consumers’ premises in order to save energy, reduce cost and increase reliability and transparency. It will overlay the electricity distribution grid with an information and net-metering system.

Such a modernised electricity network is being promoted by many governments as a way of addressing energy independence, global warming and emergency resilience issues. Although the smart grid concept may not be implemented locally for some time in South Africa, the fact that the country will follow global trends cannot be ruled out.

In the US, five to 10 years ago, industrial companies were typically able to sign contracts with their energy suppliers to lock in the cost of energy for a six to 12-month contract period. But with the opening up of the power grid system, those kinds of contracts have gone away. Today, it is not unusual for a company’s cost of energy to change frequently, such as is the case for one Arizona copper manufacturer whose energy costs change typically about 48 times per day.

Managing the cost of energy will produce a competitive advantage over those who cannot leverage the opportunities provided by demand response, self generation, exportable distributed generation and real-time market pricing for energy. An operation must understand its energy consumption characteristics to reap the benefits and avoid the penalties while meeting the needs of its customers and the environment. Operations will incorporate new concepts such as ‘green’ scheduling as well as use-or-sell cooperative-generation capacity and load-shedding. In South Africa, we are already seeing new (although not national) players on the block of power distribution with large local companies willing to contribute their excess power assets to the national grid – but on what mutually-beneficial basis?

Undoubtedly, these concepts will be disruptive to normal operations and will affect industrial automation, maintenance, performance and asset management. In view of this, any corporate energy management application must help the organisation minimise the disruptions while enabling the opportunities and should be designed for the emerging requirements for smart grid connectivity and interaction.

Interoperability

We now know that one of the most fundamental mistakes of the last few decades in respect of industrial information solutions was that each application was developed largely in ignorance of the role it had to play in the bigger picture of the unified enterprise and with other applications – after all, if you are a hammer, everything looks like a nail.

A corporate energy management application is no exception and should be designed to interact with and complement existing meters and automation assets while providing results and reports that can be easily integrated with those of other disciplines (eg, facilities management, smart building management, etc,) in order to provide a more informative and knowledge-based platform for shaping decisions.

Conclusion

Because of its pervasive nature, energy management is a corporate initiative that demands the cooperation of all concerned. It now forms an important part of Enterprise Manufacturing Intelligence (EMI) and as such, its contribution should not be underestimated.

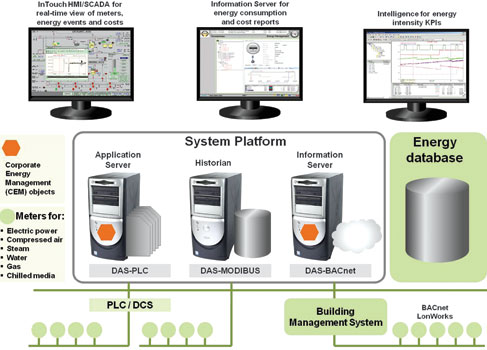

Note: The facilities, features and concepts in this article are all embodied in Wonderware’s Corporate Energy Management application which is built on the Wonderware System Platform and fully integrates with the rest of the Wonderware suite of industrial automation, MES and enterprise integration/intelligence products.

For more information contact Jaco Markwat, Invensys Wonderware, +27 (0)11 607 8100, [email protected], www.wonderware.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved