Couplings for metal shredder machines

October 2010

Motion Control & Drives

Voith Turbo secured the order for the supply of fluid couplings for two custom-built metal shredder machines at the New Reclamation Group’s metal recycling plants in Gauteng and the Western Cape.

The New Reclamation Group is a leading producer of recycled ferrous and non-ferrous metal products in southern Africa. Harry Kassel, inland operations director for the group, says that rebuilding and reinstalling shredder machines was a strategic decision based on local scrap metal market trends. “When the cost of importing new shredders from overseas manufacturers proved to be unaffordable, we decided that we were more than capable of designing and building shredder machines in-house, sourcing specialised equipment from local suppliers.

“The project kicked off in January 2009, and I went out looking for local companies that could supply the specialised equipment that was needed. Quotations for electric motors, gearboxes, drivelines, conveyor belting and electrics, all were requested. As most specialised equipment is still manufactured overseas, we selected suppliers who could deliver equipment to meet our standards of quality as well as our delivery schedules. Our determination to procure superior quality equipment from local suppliers paid off and we are dealing with companies that have enviable reputations for product and service excellence in South African industry,” explains Kassel.

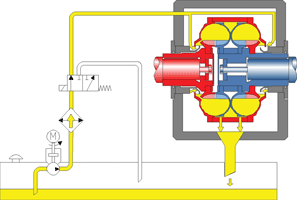

The design offers a completely wear-free drive element.

“When it came to selecting fluid couplings for the shredder machines, Voith was the only option,” he states. “We have experienced Voith’s product quality and reliability first hand. A Voith fluid coupling has been operating on our 1250 hp Lindemann shredder at our Dunswart Plant in Gauteng, 12 hours a day, six days a week, failure free for the past 16 years. This, from our perspective, is the best possible recommendation for any equipment and the entire Reclam Group has standardised on Voith drivelines.”

Voith supplied two 1150 DTP type fill controlled fluid couplings including oil supply systems and required coolers. Each drive is capable of 1200 kW at 600 rpm and offers the Voith’s unique torque limitation. Thus the motor is prevented from stalling when the shredder suddenly blocks and allows the shredder rotor to return back to full speed, thus allowing maximum productivity.

According to Kassel, the shredder operates so efficiently that the group is planning to market the custom built machines in Europe. “We built the shredder at a fraction of the cost of an imported machine, yet managed to stay within, and even improve on, European quality standards. We have no doubt that our custom-built efficient Reclam shredder machines will elicit lively interest in European markets.”

For more information contact Roy Webster, Voith Turbo, +27 (0)11 418 4000, [email protected], www.rsa.voithturbo.com

Further reading:

Wind energy in the Black Forest

Motion Control & Drives

For more than 20 years, numerous wind turbines have stood in the Black Forest and are now receiving a performance boost through repowering projects.

Read more...

Kollmorgen advances linear motor safety and performance

Motion Control & Drives

Kollmorgen Corporation has released the next update for the SafeMotion Monitor (SMM) firmware, SMM 3.0. This upgrade expands functional safety support for linear motors and linear axes, helping machine builders implement functional safety in industrial applications that require safety.

Read more...

PC-based control for additive machine tools

Beckhoff Automation

Motion Control & Drives

IRPD is a specialist in additive machine tools. Development is heavily focused on high system throughput and consistently high process quality. This goal was achieved with the help of PC- and EtherCAT-based control and drive technology from Beckhoff.

Read more...

Major software release for Parker PSD servo drives

Parker Hannifin - Sales Company South Africa

Motion Control & Drives

Parker Hannifin has released its PSD servo drive family delivering new control modes, advanced synchronisation functions and performance optimisations designed to improve throughput, accuracy and system efficiency in demanding industrial applications.

Read more...

Robotic positioning system drastically reduces changeover times

Beckhoff Automation

Motion Control & Drives

At the SLAC National Accelerator Laboratory in Menlo Park, California, an advanced robotic system by Square One Systems Design and Beckhoff speeds up high-energy physics experiments.

Read more...

Lubricant contamination costs more than you think

Motion Control & Drives

Lubrication Engineers has identified that 90% of lubrication contamination happens during storage and dispensing, not during application. To address this costly problem, it offers the isoPOD, a portable ‘plug and play’ lubrication storage and dispensing unit that’s a first for the South African market.

Read more...

New generation surface drill rig

Motion Control & Drives

Epiroc South Africa is launching a new and improved PowerROC T45. This new generation surface drill rig offers increased fuel efficiency and high availability, and is a welcome addition to the PowerROC family.

Read more...

How vision-guided robotics is transforming South African manufacturing

Yaskawa Southern Africa

Motion Control & Drives

In South African manufacturing, the final stages of production need more than manual labour or conventional automation. For many, vision-guided robotics is becoming the solution to smarter, more flexible end-of-line processes.

Read more...

Transporting substations for the world’s largest offshore wind farm

Motion Control & Drives

Dogger Bank Wind Farm will be the world’s largest offshore wind farm when it is completed. Mammoet was involved in providing transportation and weighing of the project’s three offshore substations.

Read more...

Lubrication application a key component for wire rope longevity

Motion Control & Drives

As part of its extensive work to help develop benchmarking standards for wire rope lubrication in South Africa, lubrication specialists Lubrication Engineers South Africa has found the Viper wire rope lubricator to be a key element for effective lubrication application and rope maintenance.

Read more...