In Part 4 we saw how MES is the manufacturing company’s information hub, needing seamless access to operational and business data sources. While a great deal of work has been done to simplify the exchange of information between ERP, MES and control systems using standards such as ISA-95, work is also being done on what information should be communicated and for what purpose. High on the agenda of CEOs worldwide, is performance management at all levels of their organisations that increase opportunities for improvement through the availability of right-time and relevant information – in other words, IT in manufacturing as well as everywhere else.

Having structured the enterprise as an engine for realising the company’s business objectives (see Part 1 of this series), it is now time to measure its performance against set criteria and to take remedial action where necessary. Generally speaking, performance measurement is currently only being applied to the business generation (sales) and wealth creation (manufacturing/production) aspects of the organisation. But performance management applies to each and every process and sub-process of the company – from accounting and logistics to HR and information management, because they are all cogs in the objective-realisation machine.

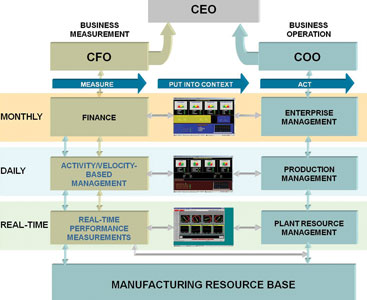

In 1999, Wonderware launched its vision for a plant-centric manufacturing approach, which showed that, as the people primarily responsible for creating the company’s wealth, shop floor operators needed to be the most informed. It is they who run the production machine and are the source of valuable information about the company’s processes. In future, accountants may have to account for more than just debtors and creditors, because right now they have at their disposal the tools to not only measure overheads and expenses but also ROI and productivity – all in real-time.

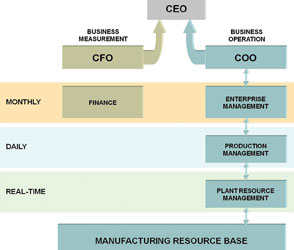

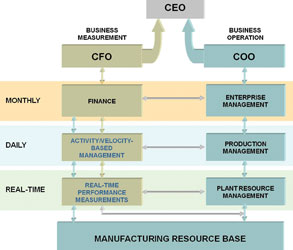

In 2003, Dr Peter G. Martin, vice president at the performance measurement and management unit of Invensys Production Management, introduced the concept of Bottom Line Automation: a concept that extends business performance measurement beyond traditional accounting to the realities of real-time production. It was developed after more than 300 CEOs underlined the inability of their office systems to provide the information required to address problems in a timely manner.

What executives are looking for?

Since technology is no longer an excuse, we are left with the challenge of getting companies to think and operate as single, unified entities whatever their size or geographical distribution – and that is a little trickier than you might think. Yet, if we take it back to basics, what are the primary challenges that executives say they face today?

* Establishing the value of the enterprise’s activities and initiatives.

* Better information from accounting.

* Higher resolution costing and profit information.

* Having employees aligned with the business strategy.

No mention of ERP, MES or automation, because the critical factors that make companies successful apply to the organisation as a whole. These factors are tightly aligned to the company’s strategy for achieving its objective and what is needed is an approach that truly optimises the merging of human and technological resources. That is where DPM (dynamic performance management) comes in.

Dynamic performance management

Capitalising on the fact that access to enterprise wide information is no longer a problem, DPM focuses on supplying individuals the exact information they need to monitor and adjust their activities and performance in terms of the company’s profit strategy and that means stepping across the artificial boundaries of ERP, MES and automation.

Why?

1. CFOs need some production and financial information as well as a good reason if they are to authorise or veto the installation of new plant.

2. Production managers need scheduling, customer and production information if they are to optimise throughput.

3. Production personnel need maintenance information and some financial feedback if they are to remain profitable and competitive.

In 2005, Martin addressed this subject as keynote speaker at Wonderware Southern Africa’s 13th User Group Conference. He showed how companies worldwide are benefiting from the application of DPM. CEOs less than satisfied with their current approaches wanted to map this into their organisations. Most of them had the following in common:

* They no longer want to work with isolated solutions and want an holistic approach to their information needs.

* They need access to up to date financial and operational information all the time – not just after month end.

* They need to monitor cause and effects at the operational level while measuring their impact at the financial level.

* They want to share their responsibilities with the rest of their staff who need right time information to be effective at all levels.

It is important to understand that implementing DPM need not entail purchasing more hardware or software. Many manufacturers already have most of what is required and the technology needed is not at all new. We can measure and monitor anything we want. The important thing to realise is that we can measure and control business processes just like we can measure and control production processes.

Extending business performance measurement beyond finance into the real-time world of MES and production will mean that IT of the top floor and IT of the shop floor will have to work in concert if they are to deliver the information goods at all levels of the organisation in time frames that will allow for corrective action to be taken. If this sounds complex, it is, in fact, less complex than what happens in the real-time environment on shop floors every day.

DPM is not simply a package that one installs and runs. It has to be crafted for each company depending on the systems they have, the information they need at all levels and, most importantly, the attitude of management and staff towards an environment where transparency and performance accountability are key. While the bottom up approach has driven manufacturing companies to new heights over the last few years, DPM is a top down approach driven by CEOs, CFOs and COOs who realise the benefits to be had from measuring their business processes with the same efficacy as their production processes.

Conclusion

Once the wealth creating machine has been built, its operators need information to optimise its performance. This requires both a micro and macro perspective without ever losing sight of the company’s business objectives.

Employees must be able to go home at night knowing how much they contributed to the business effort that day. Many control and information systems are built to be as autonomous as possible to avoid human error. This certainly has its place, but actively blotting out human ingenuity is neglecting a huge potential asset whose contribution is quite possibly the quickest and most substantial way of improving business value. Employees are seldom included in the big picture or shown how they can make a difference directly. IT in manufacturing makes the picture visible and provides all contributors a real-time window of their contribution. Where implemented, DPM has provided results in a matter of weeks, orders of magnitude beyond what can be achieved by tweaking processes or buying expensive technology.

In the next and final part, we will look at some of the questions that this series of articles may have triggered in your mind.

For more information contact Deon van Aardt, Wonderware Southern Africa, 0861 WONDER, [email protected], www.wonderware.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved