Until recently, information technology has always been considered the province of any enterprise’s business units with responsibility for business administration. But that is all changing – IT is IT – wherever you find it, and some of the principal sources of strategic information are the plant floor, maintenance personnel, the mobile workforce and many more. So ‘IT in manufacturing’ transcends barriers and looks at the information that a manufacturing or mining company needs to operate effectively and profitably in today’s torrid economic climate.

With the exponential progress that is being made in computer technology, IT in manufacturing is more about the information and less about the technology, which, today, is no constraint at all.

Memory lane

In the 1970s, data processing personnel knew a great deal about the technology at their command but they did not have the same grasp of understanding when it came to the information needs of their ‘customers’. These customers were initially the business and administration divisions of the company. The other side of the coin was that the people who required the information knew what they needed but had little clue on whether the technology could supply it. This was an era where technology was regarded as senior to its purpose.

As to having data processing assist the technical areas of the company, well nobody had ever heard of such a thing – what would they think of next? Actually using computers to help create wealth? Ridiculous – it would never catch on. So engineers started using programmable calculators (later to become desktop computers and laptops) to get the job done. Do not laugh – this scenario has existed for nearly 40 years and is still with us today! That is why we have to consider the role of IT in manufacturing rather than its role only on the top floor.

About enterprise information – three approaches, one need

Information is the universal business and operational lubricant that must operate under the most adverse conditions while protecting all the moving parts of an enterprise. It is the common denominator that defines the enterprise as a single unified entity with specific business goals rather than as a disjointed bunch of operational units each looking after their own agendas.

In fact, it could be said that the tail is wagging the dog because it is the need for information that is driving companies to become united entities rather than the conscious decision to become united through information. The need for knowledge is the driving force behind enterprise integration – and this is a good thing because there is no going back now.

We are in a time where we can see both sides of the fence: there are those mining and manufacturing companies who see information as the strategic tool it is meant to be at all levels of the enterprise while others prefer to stick to the departmentalised, insular approach that they have always practiced – and this is a situation for which vendors and analysts are partly to blame.

The focused reality of solution vendors often tries to dictate what is most important. So, if you sell scada systems, you try to convince prospects that their companies will simply stop if their production stops – entirely true but production is there to fill orders according to a schedule and does your scada system do that too? If you sell ERP systems, what could be more important to your prospect than CRM or accurate maintenance and production schedules – but ERP systems do not actually help produce stuff, do they? And if you are selling MES solutions, then you are really in trouble because you are trying to convince your prospect that everything is important because what you are selling is the enterprise’s information hub that has to reconcile business needs with production reality.

These three different approaches to supplying mining and manufacturing enterprise information have led to an unnatural perception that one information source is superior to another depending on who has got a bigger budget at the time. Analysts go along with the flow and coin new acronyms, approaches and predictions which solution vendors are only too eager to support in a self-perpetuating need-generation cycle. In the middle of all this is the enterprise, which, being already fragmented departmentally, is trying to find solutions that conform to this departmentalisation because that is how solutions are structured by their creators. The result is what we have today.

In reality, it is the enterprises that should be dictating to suppliers what to do to satisfy their information needs but it is not that simple. Do companies actually know what they need? Business managers want operations to meet production schedules come what may – because sales is what they will be rated on. Production managers want no plant stoppages and optimal efficiency because their bonuses depend on it.

This goes back to the insular model which we know cannot work because it does not reflect reality. If the business manager was to ask himself what information he could provide the production team to meet his customers’ needs or if the production manager was to ask himself what information he could provide the maintenance team to minimise downtime, it would be a start to thinking ‘outside the box’, getting the required results and not having to blame someone else for non-performance.

What is information trying to fix?

The objective of information is enterprise integration which, in turn, leads to seamless, right-time decision support throughout the organisation. The strategies of the top floor need to me made within the constraints of the shop floor. Costing needs to look at overheads as well as benefits (today we only measure overheads because we cannot/do not measure benefits, but more about this later). These and hundreds more issues need a seamless interconnection of information flows that transcend traditional boundaries. This information also needs to be available at the right time if it is to be useful. On the shop floor, the time scale is that of realtime (as it happens). In admin, the time scale could be days, weeks or even months. But it is all information and it is all interrelated. Today, it is also what the business depends on for profitable survival.

As the worlds of plant automation and business systems start to overlap, the functionality offered by the automation and plant information systems vendors is becoming more relevant than ever. But it seems that few CIOs and IT managers realise this as they still look to traditional suppliers for business solutions that are inherently disconnected from the plant floor or have poor interfaces to production systems.

From admin to manufacturing, information is the common denominator of every function within the organisation. If everyone got the right information when they needed it, they would be able to make better decisions and cooperate better with their colleagues to the benefit of the company. This is obvious but what is not at all obvious is how to actually make it all work.

IT has often been regarded as the hub of the company (especially by IT managers) – but there again, so has finance (according to financial directors) and manufacturing (according to production managers) – if you are a hammer, everything looks like a nail. It is time to put things in perspective.

Building a wealth-creating machine

One thing we know what to do is make machines and what is a manufacturing company if not a machine for turning prospects into customers and raw materials into finished goods. A by-product of these activities is profit. For a machine to operate properly, the following must be addressed:

1. What the machine is supposed to achieve (ie, competitive and quality finished goods, create a market, return a profit, etc) – addressed in Part 1 of this series of articles.

2. A design that will make the machine achieve its purpose – see Part 2 for a suggested company structure that focuses on achieving the company’s objective.

3. Reconciling the different needs of the machine’s fast and slow-moving parts – see Part 3 on how to reconcile the information needs of manufacturing, production and business systems.

4. Adding mechanisms that help the machine deal with outside demands while making the most of available resources – see Part 4 where MES becomes key to reconciling business strategy with the realities of shop floor capacity.

5. Measuring the machine’s performance and operational parameters – see Part 5 where the concept of Dynamic Performance Management extends status and performance measurement to every part of the enterprise.

How does it work?

Contrary to popular belief (and with the exception of mints), companies are not created to make money. They are formed in order to sell added value and that’s where the money comes from.

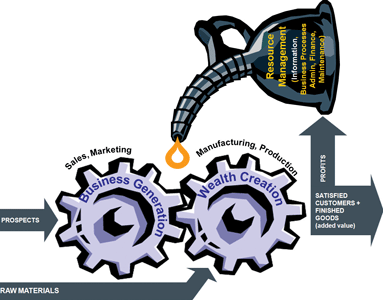

Figure 1 shows a simplistic view of a manufacturing company. The business generation process (sales and marketing) turns prospects into customers for the goods manufactured by the company’s wealth-creation process, which adds value to raw materials by turning them into finished goods. The Boeing Aircraft Company, for example, sells aircraft to the world’s airlines and adds value to aluminium by making it fly predictably for them. Everything else (resource management – functions that all companies do) is in support of these two vital processes, which are unique to each company and which characterise them to the outside world. None of these three elements (business generation, wealth creation and resource management) can operate independently from the other two. So, thinking that IT, finance or anything else is somehow senior to something else is simply irrational.

If viewed in this way, the company becomes a mechanism or machine for creating wealth through a process of selling added value to customers through processes that are supervised and controlled by its personnel. From toasters to communication satellites, we really know how to make machines work and, in the end, that’s what enterprise integration through information is all about – applying what we know about making machines work to companies.

In this day and age, the fragmentation of companies into autonomous mini empires under the control of budding megalomaniacs is no longer tenable. Grouping things in boxes like enterprise resource planning, manufacturing execution systems or scada is great as long as these terms are used to describe sets of functions rather than to divide companies into factions or to place boundaries where there should be none. And terms like ‘division’ or ‘department’ do not help either. The functions that a company carries out in order to achieve its objectives are all interconnected to a greater or lesser degree. It is enterprise integration through the concept of IT in manufacturing rather than the king’s men that will put Humpty Dumpty together again.

Who should read this and why?

This is the first in a series of articles primarily aimed at managing directors, financial directors, chief information officers, IT managers, production managers and engineers. That is because the adoption of IT in manufacturing is a top down thing, although it will need a bottoms-up buy-in of everyone it will affect. This should also be read by anyone who is keen on making things go right for their companies.

It will help put business and operational processes in the proper perspective so that all involved can see for themselves why across-the-board IT is essential. It highlights some of the problems and suggests some solutions. It also cuts through the maze of complexities companies find themselves in today by highlighting what really matters. Finally, this should be read because it sells nothing but common sense – no revolutionary new approaches, no snappy three-letter acronyms and no proprietary technologies. Manufacturing IT is not something you buy – it is something you do.

The scope of IT in manufacturing is more than getting shop floor systems, MES (manufacturing execution systems) and ERP (enterprise resource planning) systems talking to one another. An integrated information environment is going to trigger changes in everything from accounting to accountability. And that is where the real benefits lie.

For more information contact Deon van Aardt, Wonderware Southern Africa, 0861 WONDER, [email protected], www.wonderware.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved