Wireless process automation technology presents compelling opportunities for process manufacturers to implement applications that they simply could not justify with traditional wired technology. Wireless enables access to remote devices at hard to reach unmanned sites and blind spots in a facility where measurements are not taken as often as they should be. By adopting wireless, operators, maintenance and IT personnel, and plant management gain convenient access to information previously unattainable.

Wireless process automation technology presents compelling opportunities for process manufacturers to implement applications that they simply could not justify with traditional wired technology. Wireless enables access to remote devices at hard to reach unmanned sites and blind spots in a facility where measurements are not taken as often as they should be. By adopting wireless, operators, maintenance and IT personnel, and plant management gain convenient access to information previously unattainable.

If the desire is to gain access to additional operations and maintenance information, the obvious attraction of wireless is the major savings as compared with wired installation. For example, installing additional wired measurements within hazardous areas of a chemical plant or refinery is often cost prohibitive. Wireless reduces this installed cost by as much as 90%. Installation is simplified since it is not necessary to plan and run conduit and cables to every device. Users are relieved of the complexity and limitations of physical wiring.

Self-organising networks

There are various wireless technologies available for a range of industrial applications but not all are suitable for the harsh environments found at most process plants including the inevitable canyons of steel that can present problems for wireless signals. Fortunately, self-organising wireless mesh networks will overcome the obstacles to deliver reliable, secure communications.

The self-organising wireless mesh networks combine highly reliable, smart monitoring devices with wireless transmitters, networked together using Time Synchronised Mesh Protocol (TSMP) communications technology. The networks use IEEE 802.15.4 radios with channel hopping as the physical layer, forming the basis for the recently approved WirelessHART open standard. They are designed and tested to be tolerant to almost all interference and can co-exist with other wireless networks in the plant.

As new devices are added, they connect automatically to the self-organising network. New devices beyond the range of a gateway pass their messages through other wireless devices until they reach the destination. This wireless mesh technology makes devices easy to install since extensive site surveys are unnecessary and each device is ready to connect when installed. If something disrupts communication between devices, the self-organising network recognises the problem and automatically re-routes communications along the next best path. This results in communications reliability greater than 99%.

Self-organising network technology simplifies set up of a successful wireless network. Traditional point-to-point wireless networks require a site survey to ensure that every node in the system has a line-of-sight path. This survey work is expensive and also tends to require up to three times as many infrastructure nodes as a self-organising network. Another advantage of self-organising networks is that they are dynamic. As new obstacles are encountered in a plant - such as scaffolding, new equipment, or moving vehicles - the networks can reorganise around them. All of this happens automatically, without any intervention by the user.

In 2006, Emerson Process Management introduced Smart Wireless solutions using self-organising mesh technology with TSMP protocol, thereby extending and unplugging its PlantWeb digital plant architecture to connect intelligent field devices wirelessly. Smart Wireless incorporates wireless instruments that are fundamentally the same as those used elsewhere in the plant, including having the same process connections, which means that technicians are familiar with them. Emerson addresses the issue of security by providing advanced, standards-based AES 128-bit encryption as well as identification, authentication and validation techniques, verification, key management, and direct sequence spread spectrum (DSSS) anti-jamming techniques.

Smart wireless has been adopted by a broad range of end users in various applications including wellhead and heat exchanger monitoring at the StatoilHydro Grane offshore platform, temperature and tank level measurement at PPG Industries, and providing continuous monitoring for detection of potentially hazardous rising temperatures in railway wagons at Croda.

Plant wide availability

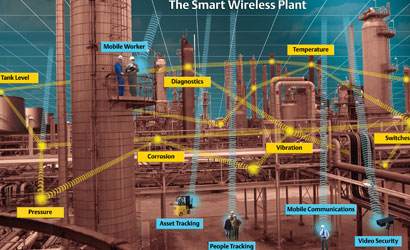

Having collected more data, the next logical step is to make it more readily available to those that need it. By using the information received from a broad range of available wireless devices within the control network and then introducing technologies such as Voice over Internet Protocol (VoIP), video and handheld tablets it is now possible to make the data available over the plant wide network. This enables end users to track people or assets, send alarms and provide historical or live data to mobile operators.

Emerson recently announced that it was collaborating with Cisco to offer open-standard solutions for wireless process and plant management applications that install easily and operate reliably in challenging industrial environments. By using tools normally found in the office environment such as e-mail or Internet operators can be made more effective. This is achieved by integrating Cisco wireless access points throughout the plant giving plant wide coverage.

For example, a maintenance operator who is already out in the plant is now able to receive valve diagnostic information directly to his handheld PC. Should there be a fault with the valve he will know exactly what is wrong with the device and how to fix it quickly, thereby improving efficiency. In addition, the safety of maintenance and operating staff is paramount and the introduction of wireless within the plant is starting to enable fieldworker communication and location tracking.

Conclusion

Wireless technology is not a complete replacement for wires, at least not for a while, but by using the information received from incremental measurement points and dedicated maintenance devices within the control network it is possible to not only automate operator rounds, but also to gain a better insight leading to significant improvement in plant efficiency, reduced maintenance schedules and increased times between scheduled shut downs. Wireless self-organising mesh networking solves the problem of reliability within tough non-wireless friendly areas. Security issues have been addressed and the WirelessHART standard gives the process industry an open standard to rely on. By adding plant wide wireless infrastructure it is now possible to improve the availability of this extra data to those that need it most.

For more information contact Widad Haddad, Emerson Process Management Dubai, +971 4 883 5235, [email protected], www.emersonprocess.com

© Technews Publishing (Pty) Ltd | All Rights Reserved