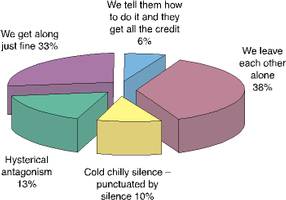

Merging the disciplines of IT and process control through effective collaboration is no doubt the way to achieve a unified and profitable enterprise. But reality is far removed from this happy scenario. According to a poll conducted by Control Engineering magazine in September 2004, only a third of plant floor and IT personnel get along, while the remainder either ignore each other or cooperate in the legendary manner of cats and dogs.

While traditional IT believes that plant floor IT is also their responsibility, they quickly change their mind when they see what is involved. Many knowledgeable observers believe that this is one of the principal causes of failure for integration initiatives.

AMR Research has stated that: "The disconnect(ion) between realtime operations and business systems hinders improvements in enterprise-wide manufacturing performance." But when this disconnection is addressed through the concept of enterprise manufacturing intelligence (EMI), results can be immediate and impressive. AMR maintains that most implementations pay for themselves in six months or less despite widely varying initial project scope and application by industry.

Whatever the claims, it is clear that the merging of these disciplines is an inevitable necessity in a competitive world - but who is going to drive it? ERP, MES and industrial automation solution vendors are starting to provide impressive tools to facilitate application integration both horizontally and vertically while standards such as S95 prescribe clean interfaces for the exchange of information. So, the problem has less to do with technology than ownership. It is probably time to look at the reality of the situation rather than opinions based on decades of prejudice.

ERP inputs come from a variety of sources. Many of these are handled in an off-line batch format and many are handled on a quasi realtime transactional basis. The result of the processing of input to output is extremely important - however, not all inputs need to be handled immediately. As a result, many of the processes can be outsourced - even to another country. Alternatively, the manpower required to operate the IT environment is also often outsourced.

Realtime process automation inputs come from thousands of sources, need to be interpreted immediately and the outputs must correct processes within the timeframe of milliseconds to avoid life-threatening situations, expensive damage or equally costly production delays. This has, to date, never been outsourced and the outsourcing of the people managing this automation process is very rarely outsourced.

Quite apart from the practical and technical reasons why realtime processes are not outsourced, lies a more fundamental reason. Manufacturing companies, not entirely by accident, were created to manufacture things. That is the core of their being and reason for existence. And that is another reason why what they do cannot readily be outsourced. Bits of it can, but the Widget Manufacturing Company wants to be seen as the source of leading Widgets. If it outsources this, what will it be known as? The Widget Invoicing Company? - Not likely, because that has also been outsourced. This is not to say that a manufacturing company cannot become a paper company but somebody somewhere, at the end of the outsourcing chain, has to make the stuff.

Realtime and near-realtime processes in scada and MES have their own distinctive IT requirements that are far removed from those of the ERP environment - yet both are needed by management that are trying to steer their companies towards better times. Traditional IT cannot cope with the realtime world of production - but what about the other way around? Let us not forget that there is no 'seniority' in this exercise - simply functionality.

While production cannot produce without a sales and admin force to define the product requirements, top management is also powerless without information from below. So, if you are an automation engineer looking to spread your wings and make yourself more valuable in a growing market, you could do a lot worse than adding 'IT Specialist' to your portfolio. Whether your company outsources its ERP or not, you are in a unique position to structure information links between your company's operational and business units. You have dealt with crises on the millisecond time scale; imagine the luxury of having an entire day to pinpoint the source of a problem.

What we need today is a much greater degree of real cooperation and understanding between IT and the shop floor - but that is only the millionth time this has been said. If we need action now, who is going to take the initiative? Excellent candidates are system integrators and process control engineers who at last have the integration tools (such as Wonderware's ArchestrA) necessary to do the job from a bottoms-up point of view. This would allow realtime people to manage the environment they know best while understanding the needs of enterprise IT. Conversely, IT would not have to get involved in an environment that is unfamiliar to them but would understand the source of the collated information they need for their enterprise applications. It is probably this mutual understanding and respect for each other's roles that, more than technology, will lead to harmonious cooperation and eliminate the 'cold chilly silences punctuated by screaming'.

For more information contact Mike le Plastrier, Futuristix, 011 723 9900, [email protected], www.futuristix.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved