Part 1 (April 2004 issue) looked at the PST (primary settling tank) and discussed the optimisation potential in relation to the suspended solids measurement. Part 2 takes a look at the activated sludge process, considered to be the heart of the whole process.

The activated sludge plant makes use of a biological process in which micro-organisms oxidise and mineralise organic matter. Already present in the water as it enters the system, these micro-organisms use oxygen to oxidise organic matter. To maintain the microbiological population, sludge from the secondary clarifier is recirculated to the aeration basin.

Biological nitrogen removal

Nitrogen is present in wastewater as several forms, such as ammonium (NH4+), nitrate (NO3), nitrite (NO2-) and as organic compounds. While the microbiologists may tell us that nitrogen is the food for biological growth, the presence of nitrogen in wastewater, however, presents many environmental problems. Most nitrogen is present in the form of ammonium when it flows into the wastewater plant. Nitrogen can be removed by a two-step process called nitrification and denitrification.

In nitrification, micro-organisms consume organic carbon as food and the result of this is the production of CO2, H2O and an increase in the population of these micro-organisms. Some of these organisms transform the ammonia to nitrate.

In denitrification, step two, under low oxygen conditions (anoxic) certain micro-organisms work to separate the O2 from the NO3 (nitrate) to satisfy their need for oxygen - in this process nitrogen gas is released.

Automation is advantageous

The demands on wastewater plants increase as the resident population increases. Optimising plant performance demands improved control strategies. Control systems currently in use include simple PLC-techniques, time control - and in some cases manual control. While advanced systems have been developed over the years, none have been implemented to their full potential yet.

Why the reluctance to implement a complete automation

There are several reasons why full automatic control has not been fully introduced in South Africa, these include:

* Effluent standards have not been tight enough.

* Wastewater treatment is often considered as a non-productive process - and control systems are expensive, making it difficult to convince a plant manager to optimise solutions (a look into total cost of ownership at a later stage will help the argument of optimisation).

* Online measurement devices have typically required a lot of maintenance and in some cases have proved to be unreliable.

* Many final control elements in the existing installations (pumps, control valves and actuators) are not variable, and can only be on or off, open or closed.

* The process is complex, so instrumentation engineers often shy away from advancing into this sector of the industry.

* The application of modern control theory (like fuzzy logic and full PID) and the advanced technology of modern sensors (like the new, low-maintenance, no pre-treatment UV principle Nitrate inline sensor) can be technologically intimidating to some.

Control in the activated sludge process

There are many inter-related variables - for example, if the DO (dissolved oxygen) set point is changed both the ammonium and nitrate concentrations are affected. New control strategies can involve the use of simplified biological/physical models, feed forward control, simple estimation models, supervision control and realtime estimation.

Controlling the oxygen in the aeration basin

Over the years, DO was considered the most important measurement parameter in the aeration basin. This measurement was used to stop and start the aerators. There is nothing wrong with this control principle, but with minimal additional engineering the plant manager can achieve a greater cost saving (aerator operating cost - energy) and have better control, while adhering to quality standards on effluent outflows.

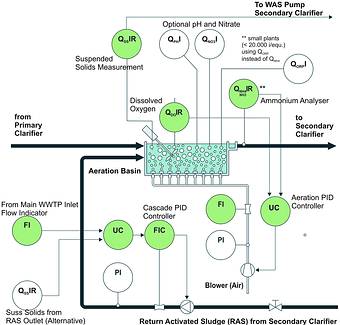

Instead of just using DO to control the aeration (whether it be by surface agitation or the injection of air), the plant manager can use an ammonium analyser together with the DO to control the airflow in the basin - smaller plants can incorporate ORP (oxidation reduction potential) measurement parameters in the place of ammonium analysers.

This can offer significant savings by preventing excessive aeration - where the aerators will only run when the ammonium levels are high, even though there might be a 'demand' for oxygen as measured by the DO measuring instrument.

Linking the inlet flow to the return activated sludge flow controller as a feed forward control loop can also have a positive impact on the overall performance of the plant. The suspended solids measuring instrument at the secondary clarifier (return activated sludge outlet) can also be used as an alternative. The implementation of these simple control measures can work to reduce the total cost of ownership, offering significant savings in running costs.

The third article of this series will discuss the cost of ownership, based on a typical control principle.

For more information contact Grant Joyce, Endress+Hauser, 011 262 8000, [email protected], www.za.endress.com

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved