As the era of the fieldbus dawns it is imperetive to ensure that all field devices can be integrated as easily as possible into the plant. This article considers the issues around which interface types are available and their pros and cons.

If you ask any plant engineer to identify the three most important process variables in his plant it would not be surprising to see that electrical energy does not feature on his list. However, you ask the same plant engineer how well his plant will run when there is no electricity and he will tell you that the plant is extremely sensitive to even the slightest disturbance in the electrical supply. It is therefore essential that the electrical parameters such as AC voltage (mean and RMS), AC current (mean and RMS), watts, VAr, VA, phase angle, power factor, frequency etc are monitored and used to help optimise the process.

We now need to consider what interface options are available and what, if any, upgrade path is available from one system to another. In broad terms there are probably two interface options available.

* Traditional 4 to 20 mA loops.

* Fieldbus technologies

We will look at these options in some detail without getting involved in the technical issues of each but rather to look at the options and decisions that need to be considered by each user depending on the specific application.

4 to 20 mA loop interface

It has been mooted that, with the advent of fieldbus technology, the days of the traditional 4-20 mA interface are numbered. With the large investment of installed product and systems worldwide there will still be a significant requirement to interface new products into this analog technology for the foreseeable future. There is no doubt that anyone who has worked in the control and instrumentation field will be well versed in the pros and cons associated with the 4-20 mA current loop.

Pros

* Simple to understand.

* A universal standard.

* Stable technology.

* Large base of people with experience in the technology.

* Wide range of products to choose from.

* Able to be applied in both intrinsically and non- intrinsically safe environments.

Cons

* Point to point interconnectivity.

* Large amount of wiring.

* Single measurement per loop.

* Difficult to fault find and maintain.

Fieldbus technologies

There are a number of fieldbus technologies that have and will continue to evolve in the new millennium. There are those that have used the same two wires normally associated with the 4-20 mA loop and superimposed additional information on it from the 'smart' instrument. There are fieldbuses that have been specifically tailored for an industry segment eg CANbus in the automotive industry or DNP 3.0 and IEC 870-5 in the electrical utility industry. There are fieldbuses that are better suited to the interoperability of field instrumentation whilst there are others that embrace the transfer of large packets of data at very high speeds. There is also the emergence of Ethernet in the industrial environment, which will allow access to freely available, cost-effective hardware and seamless transfer of plant data into the ERP environment.

From the above it is quite clear that the days of one universal standard interface are gone and that the user will need to be able to identify which interface best suits his particular application. The pros and cons associated with fieldbus technologies are indicated below:

Pros

* Substantial savings in field wiring.

* Interoperability between devices from multiple vendors.

* Ability to decentralise functionality.

* Access to large amounts of data.

* Significant savings in commissioning, maintenance and troubleshooting.

Cons

* No single industry standard.

* Lack of trained personnel who understand the technology.

* Noninteroperability of products that supposedly talk the same protocol.

* Vested interest in a particular fieldbus by large industry players.

* Upgradability of installed products with the evolution of each particular protocol.

* Limited availability of intrinsically safe products.

The task for any plant operator/manager today is to improve the efficiency of the plant. Modern electrical measurement instrumentation is now available that can facilitate this process. With this comes the challenge of maintaining the plant integrity with existing analog 4-20 mA technologies as well as being well placed to take advantage of the growing opportunities presented by the different fieldbus tech-nologies.

Issues that need to be considered when selecting the most appropriate device, manufacturer and interface system are:

* Ability of the instrument to be able to interface into the existing analog 4-20 mA as well as relay systems.

* The instrument must have a simple to use, user-friendly; PC-based Windows interface to allow for configuration and monitoring of system variables.

* The instrument must be able to be configured on site to suit any particular application ie network topology, output configuration etc.

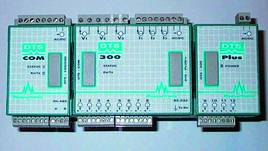

* The instrument should be modular to allow the customer to select the most suitable solution depending on his varying needs.

* A facility should be available for local display of the measured variables.

* The user should be able to customise the display to ensure that the critical information is displayed in an accessible manner.

* The instrument must be able to accommodate a wide range of fieldbus technologies and be upgradable to facilitate the improvements in these fieldbuses.

The above points can be translated into the following user benefits

* Reduced stockholding and improved inventory management.

* Flexibility.

* Reduced commissioning times.

* Quicker faultfinding.

* Networkability.

* Reduced training cost as there is one common interface.

Conclusion

It is clear that there are a number of issues that need to be considered when choosing the correct electrical measurement interface for your plant. However, by ensuring that the system chosen can address both the existing needs as well as the future fieldbus requirements, the user's investment will be safeguarded.

© Technews Publishing (Pty) Ltd | All Rights Reserved