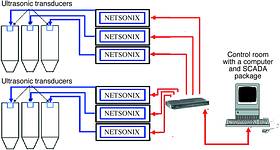

KAB Instruments has designed and patented a new concept for process control measurement that offers various networking options. The Netsonix ultrasonic level transmitter is capable of measuring levels with a range from 100 mm up to 60 m. This is possible by combining the Netsonix with the various transducers manufactured by KAB. The level that is measured by the Netsonix is then converted to Ethernet TCP/IP protocol. The Netsonix can then be connected directly into the LAN (local area network) or WAN (wireless area network) from where the customers are able to view the measurements on their scada package using KABOPC. Process conditions as well as the operational status of the instrument will be able to be monitored. The customer will be able to make changes to the parameters in the set-up menu to suit conditions on the plant without actually travelling to site.

Apart from the ultrasonic level measurement the Netsonix is also capable of accepting 10 digital temperature devices that can be connected to it with only a single cable, thus eliminating the use of a cable to every temperature point. The temperature probes are digital semiconductor devices that provide digital feedback regarding the measured value, offering high levels of accuracy. These devices are separately addressable so that customers know which temperature point is being indicated.

Combined with the level and temperature measurement the Netsonix also has the capability of accepting a 0-10 kHz, 24 V d.c. digital input. There are many uses for this function such as integrating a low-cost Pelton wheel flowmeter or the integrated output from basically any flow transmitter.

Using hubs and switches, customers can expand to as many points as they would like to view - without dramatically affecting the communication speed of their network. The expansion may be implemented by adding additional hubs and switches with either hardwire connections, fibre-optic cabling - or various wireless devices.

Another wireless technology available to the customer is wireless remote access Ethernet. An unshielded twisted pair cable transporting the TCP/IP Ethernet signal is taken from the Netsonix to an access point, which forms part of the WAN. The access point will then transmit the digital information via the WAN to another access point in the control room that is connected to the same WAN. It receives the data and then provides the information to a scada package. By using the KABOPC software/driver the information is then provided to the customer (HMI).

A typical application, for which the Netsonix ultrasonic level transmitter is well suited, is remote pump stations that are commonly used by water supply and water treatment plants. The customer may need to monitor a level in a sump, the flow rate of the liquid that is pumped to or from the pump station and there may be a need to monitor the status of the bearing temperatures on the various pumps. By using a single Netsonix level transmitter, combined with the digital temperature probes and a flow transmitter the users will be able to monitor the status of their pump station. The Netsonix level transmitter can also be set up to monitor open channel flow measurement with various pre-programmed shapes of flumes and weirs in the configuration menu.

The information regarding the measurements taken, can be sent via a wireless device which forms part of his WAN, which will then transmit the information to the control where the customer is able to view it using KABOPC software combined with his scada package.

Using Ethernet and wireless devices reduces the cost of ownership substantially as there is very little cabling involved and it is much faster than standard bus systems using hardwiring. By using GPRS (global package radio system) the information is sent via a cellphone network from the Netsonix to the Internet. This information is written to a website created by or for the customer. The customer can then access this information where he can view the status of a plant or process. This information can also be written to scada package using the KABOPC software/driver that was developed for this purpose. This offers the customer the ability to send information from any site where there is access to a service provider network.

In the chemical industry the Netsonix level transmitters can be put on stock tanks holding various kinds of chemicals for stock management on different sites. By installing a GPRS system, formation regarding stock levels can be sent directly to the manager's computer or cellphone where he will be able to monitor stock levels on different sites.

KAB has also designed and patented two other devices to work with the Netsonix. These are analog and digital input modules. The analog device reads the input from any other 4 to 20 mA device and is capable of accepting six x analog inputs. This offers the customer the ability to add pH meters, density meters or any other device that generates 4 to 20 mA to go along with the Netsonix.

The customer will also be able to monitor pump status, valve open/close positions and various other on/off conditions on the plant using the digital 8-channel input Netsonix. The information regarding the measurements taken, can be sent via GPRS or it can be fed into a wireless device which forms part of his WAN, which will then transmit the information to the control where the customers are able to view it using KABOPC software combined with their scada package.

On the more difficult applications the Netsonix level transmitters can be used for stock control on coalbunkers in coalmines and power stations. In coalmines where sites are normally very remote, the information about the bunker level can be sent from the Netsonix via a fibre-optic used by the underground network, to the control room. In power stations the Netsonix level transmitter offers a low cost alternative to a typical hardwire application. Various coal bunker, water levels, lime silos and chemical stock levels can be monitored using the Netsonix ultrasonic level transmitter. By putting all the cabling from the various Netsonix level transmitters into hubs, all the measured values can be sent to the control room on a single twisted pair cable or fibre-optic cable.

In general, Ethernet communication is much faster than any other bus currently available on the market. The standard Ethernet network runs at a speed of 10 MBps where the standard bus systems only operate at a speed of 32 KBps. Another feature of Ethernet is that thousands of devices can be added without a drastic influence on the operating speed of the network. With standard bus systems the customer is limited to between 8 and 12 devices per string otherwise it seriously impacts on the communication speed of the bus network. An added benefit for the customer is that Ethernet equipment is easily available and can be purchased from just about any computer store. On the other hand bus systems are typically proprietary type systems that are only supplied by specific suppliers. This means that the customer is forced to use expensive cabling, connectors and other hardware in order to get his bus systems up and running.

For more information contact Rudi Tuffek, KAB Instruments, 011 435 5380, [email protected], www.kabinstruments.com

© Technews Publishing (Pty) Ltd | All Rights Reserved