Since the beginning of the year everybody is talking about the twentieth birthday of the Internet. But there is another even more spectacular anniversary this year Ethernet is 30 years old! What began as a printer network interface is today an important component in process automation. The inherent flexibility of Ethernet has allowed it to meet numerous challenges, and has ensured its position as the dominant LAN protocol worldwide.

The evolution of Ethernet has been interesting as well as rapid. According to an internal memo at the Xerox Palo Alto Research Centre (PARC), on 22.05.1973, it was suggested that the integrated bus system in the copying systems, that is Ethernet, should be used as the basis for LANs. Dr Robert Metcalfe, the inventor of Ethernet at Xerox, put forward the idea of a network interface for printers using a coaxial cable. The ALOHA protocol was used as the network protocol. This protocol, developed at the University of Hawaii, uses radio links for the exchange of data between the various institutes located on different islands.

The 'pure ALOHA system' devised by Prof Norman Abramson uses a set frame size and transmits whenever there is something to be sent. Collision-free transmission is only possible up to a network load of 18%. Using the 'slotted ALOHA system' developed by Metcalfe, an improvement in the cycling of the transmissions is achieved, by transmitting data at specific times. In this way theoretical collision-free transmission up to a network load of 37% can be achieved. In the next step Metcalfe expanded the idea with a listening mechanism that first checks whether a channel is free (carrier sense), and developed an intelligent collision detection method to resolve the conflict when two stations transmit at the same time (multiple access). The Ethernet CSMA/CD method was born.

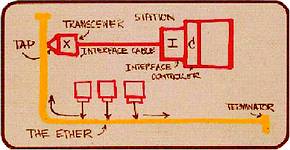

The Xerox Ethernet with 2,94 Mbps, for up to 100 workstations and a maximum of a kilometre of coaxial cable (drawn in yellow in Figure 1), was so successful that the DIX group (DEC, Intel, Xerox) expanded Metcalfe's Ethernet to the data rate of 10 Mbps. The proprietary Ethernet V1 specification was published in 1980. In June 1983 the IEEE 802.3 standard, based on the DIX draft, was ratified by the IEEE (Institute of Electrical and Electronics Engineers) under the name CSMA/CD (carrier sense multiple access/collision detection). Today this continues to be referred to in everyday speech as Ethernet (Ethernet V2).

The maximum length of the yellow coaxial cable (10Base-5) is 500 m (see Figure 1). Terminal devices are connected to the cable using special vampire transceivers. During this process a hole is first drilled in the yellow cable so that the transceiver can be screwed onto the cable and a contact pin can penetrate to the inner conductor, thus making the contact between the terminal devices.

Due to the low licence fee (a lump sum of $1000,00) the DIX Ethernet specification rapidly became widely used. This paved the way for further standardisation and expansion of the network technology. In the meantime, Ethernet has proven itself in office networking for more than 20 years. Modern standards such as switching, full-duplex transmission, prioritisation of realtime data and the possibility of scaling bandwidth from 10 Mbps to 100 Mbps, or even 1000 Mbps, also make this protocol the first choice for usage in the industrial sector.

Today, Ethernet is successfully employed at the management level and the process measurement and control level in data networks across companies. Even at the field level, ie, in the vicinity of the process, Ethernet is increasingly prevalent. A significant factor in this evolution is the deployment of network components and connectors suitable for industrial use. These have also recently become available with protection class IP67, indicating that they are designed for installation directly on the machine.

Standardisation at IEEE 802

The IEEE is the largest technical association in the world and has project groups working on all important and innovative technical areas. In the IEEE, standards are drafted, various technologies and topics suggested and debated, and work performed and discussed in the working groups. All LAN protocols in common use today are described by the IEEE-802 model and are documented in the various IEEE 802 standards. The name of project group 802 resulted from the project start in February 1980. Shortly after its formation, the IEEE 802 standardisation group published three of the LAN protocols best known today: Ethernet, Token Bus and Token Ring. Of these, Ethernet is the only protocol that continues to be in common use and is the most widely used transmission technology, with an installed base of more than 95% in the office sector.

In 1985 Ethernet evolved to the 10Base-T standard (IEEE 802.3i). This uses a UTP cable instead of coaxial cable. In 1995 the Fast Ethernet standard (IEEE802.3u) with 100 Mbps was introduced. As early as 1998 Gigabit Ethernet was standardised by the 802.3z group, initially based on glass fibre, then in 1999 by the 802.3ab group based on UTP cable. In 2002, 10 Gbps Ethernet was ratified as the IEEE 802.3ae standard. For the first time Ethernet was standardised not just for LAN networks, but also for WAN usage.

Today, in 2003, the next step for Ethernet is being discussed in the IEEE. Here two groups have formed, one of which favours a 40 Gbps Ethernet solution and the other 100 Gbps Ethernet. The plenary meeting itself takes place three times a year. For a number of years Hirschmann Electronics has been one of the few German members to always be represented at these meetings.

The experts

The development of Ethernet and Ethernet components has always been linked to the name of Hirschmann. As early as 1984 the first Ethernet star coupler (Ethernet hub) that could be equipped with different transmission media was put into operation by Hirschmann. At the university in Stuttgart an optical Ethernet-LAN was installed - the world premiere for Ethernet based on fibre-optic networks. Autumn 1999 saw the foundation of IAONA Europe, firmly establishing Ethernet's presence in the automation field. Hirschmann was one of the four foundation members.

Where did the name Ethernet come from?

Ethernet was named after light ether. It was at one time assumed that where there are (light) waves - that is oscillations - there must also be something that oscillated. This oscillating something was called ether.

James Clerk Maxwell (1831-1879) stated on this topic: "Ether was invented so that planets can float in it, to accommodate electrical atmospheres and magnetic radiation, to transmit sensations from one part of our body to another and so on". The properties of this medium proved to be exactly those that were needed to explain electromagnetic phenomena.

Only after the Michelson-Morley experiments, in which it was shown that waves propagate relative to a moving body in all directions at equal speed, did it become clear that only one conclusion was possible: ether does not exist! But the name is still alive for a very successful technology.

The author

Thomas Schramm (Dipl.-Ing. Communications Engineering and Economic Science) is Manager of the Consulting team, part of the Competence Centre of the Automation and Network Solutions division at Hirschmann Electronics. He is an active member of BGNW (Head of working group) and IAONA. Schramm is one of the few Germans who work directly with the IEEE for the development of Ethernet. www.hicomcenter.com

| Tel: | +27 12 657 3600 |

| Email: | [email protected] |

| www: | www.iacontrol.co.za |

| Articles: | More information and articles about Industrial Automation & Control (IAC) |

© Technews Publishing (Pty) Ltd | All Rights Reserved