Critical temperatures with a plant or process have the potential to cause or inflict tremendous loss if not monitored and controlled. Also important is the time of occurrence of temperature fluctuations in monitoring and improving plant or process effectiveness and understanding the dynamics of the process under examination. Scada is an option commonly used but it can prove costly and in particular where small numbers of temperatures are to be considered.

High temperatures can be early warning signs of wear and tear, component stress, overload, seasonal changes or part of a process under control. In many cases the ubiquitous digital panel indicators with trips and re-transmit facility are used in these applications, however, transient high temperatures are often not noticed until a more serious condition arises. Very often temperature monitoring is not localised but spread widely throughout the plant which necessitates large scale wiring to bring the information back to a central point.

This new generation temperature monitoring system caters for up to 16 temperatures at once. No multiplexing and no rotary switches. Temperature inputs may be any 3-wire RTD or thermocouples. Cold junction compensation and linearisation are standard features.

Alarms and alarm annunciation

Each temperature input has an alarm and trip setpoint allocated to it. Setpoints are configurable via the front panel keypad. Each setpoint is represented by an LED indicator, which can be configured with an optional annunciator sequence forcing an operator to silence the audible, and acknowledge the flashing alarm LED. An auto reset or manual reset option can be chosen so that alarms can be trapped in applications where operators may not be present at all times.

Temperature channel display

Each temperature channel may be viewed in turn on the front panel LCD display with its setpoints by using a scroll button. OmniWatch has an option to automate the display so that the display automatically scrolls through the channels at a specified time interval.

Alarm and trip outputs

Each setpoint can have a relay or open collector output for the alarm status; these can be used to drive external devices when the setpoints are reached.

Group alarm function

To save on relay outputs, group alarm functions are used to bring up alarm for the attention of operators. There are four group alarms: one each for setpoint 1 and setpoint 2, and one each to function as a high high or low low group alarm. Every input is mapped to the group alarm.

Optional re-transmit

The temperature inputs can be re-transmitted to another device as 4 to 20 mA outputs by simply fitting an analog output module to the OmniWatch.

Date and time stamp of alarms

Every alarm or trip is date and time stamped as it occurs. This is imperative where unmanned stations are visited periodically and the recording of alarm and trips present an audit trail of what happened. These events are also available to the Conet local area network, which can then route them to a scada database system.

History log

OmniWatch has a history log, which captures the last 64 trips, and alarms with its date and time stamp and this can be viewed via the front panel of the OmniWatch. Operators thus have access to the latest information.

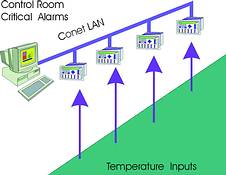

Local area network connections and scada

Up to 126 OmniWatch devices may be connected to a single twisted pair cable running the Omniflex local area network - Conet. This amounts to a total of 2016 temperature channels on a single twisted pair cable. Conet is supported by most scada packages and can thus acquire the information from OmniWatch devices including all date and time stamped information. Predictive and preventive maintenance systems can utilise the data for pro-active plant management

Each OmniWatch unit has the following features:

* 16 temperature channels.

* Alarm annunciation/indication for temperature alarms and trips (32 indicators).

* Display in degrees C or F.

* Front panel configuration or via PC.

* Re-transmit option (4 to 20 mA) for temperature inputs.

* Group alarm and trip facility.

* Optional independent alarm and trip outputs.

* Date and time stamp of alarms.

* History log of last 64 alarms and trips.

* Up to 126 OmniWatch units on a twisted pair.

* Scada compatible.

Building upon the 30 plus years of experience in the field of alarm and events monitoring instrumentation for industry, Omniflex continues to provide solutions for many plant applications such as temperature monitoring.

For more information contact Ian Loudon, Omniflex Automation Products, 031 207 7466, [email protected], www.omniflex.co.za

| Tel: | +27 31 207 7466 |

| Email: | [email protected] |

| www: | www.omniflex.com |

| Articles: | More information and articles about Omniflex Remote Monitoring Specialists |

© Technews Publishing (Pty) Ltd | All Rights Reserved