The pH IsFET sensor was initially developed for application in the food industry, and is manufactured without glass and complies with hygiene requirements. However, due to its measuring principle and technology, Endress+Hauser’s TopHit H pH IsFET (Ion sensitive field effect transistor) sensor has made inline measuring significantly easier in the processing and pharmaceutical industries, as well as achieving cost savings.

TopHit H measures the pH value using an IsFET chip. The chip is embedded in a PEEK polymer sensor body, a very stable material in terms of its mechanics and chemistry, and is approved for use in the pharmaceutical and food industries. TopHit H is constructed with FDA (Food & Drug Administration) listed materials, is non-toxic in accordance with FDA, and also fulfils the criteria for sterilising and cleaning. The sensor has the dimensions of a normal 120 mm long pH glass electrode and can, therefore, be used with all the usual assemblies on the market (Figure 1).

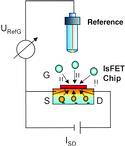

The part of the chip in contact with the medium is called the gate. A pH-dependent Nernst voltage forms in the medium on the surface. This voltage generates mirror charges on the inside of the chip which modify the resistance between the source and drain of the field effect transistor (Figure 2), thereby making measurement of the pH value possible. The Nernst layer on the gate does not undergo hydrolysis, glass is not used as ion-sensitive material, and there is no internal electrode.

However, a reference electrode is still necessary since IsFET technology requires a known voltage reference point. Measurement takes place via two circuits and is fundamentally different from the principle used with glass electrodes. The voltage circuit to the medium (via the gate) has extremely high-impedance, while the electric circuit via source and drain has low-impedance (10 to 3 Ω).

The device provides new measuring principles, as well as new applications, together with cost savings, and ease of operability. The features that make this possible are explained in the remainder of this article.

Non-glass sensor

The most important characteristic of IsFET technology is its non-glass construction. In numerous areas of food industry technology, this means that inline pH measurement is now possible for the first time, including applications involving dairy products, or in the production of mustard, tomato sauce (Figure 3) or jam. More importantly though, is the measuring possibilities opened-up in the pharmaceutical and biotechnology industries where glass measurement is not possible.

Horizontal installation allows a hygienic connection

Previously, pH measurements in hygienic applications were avoided, because traditional glass electrodes necessitated an installation angle of at least 15°, in order for the internal electrode to cover the membrane. However, due to this 15° rule, 'dead spaces' on the process connection result, making it either impossible or very costly to hygienically clean the connection.

In contrast, this sensor can be installed horizontally in the process, making a flush connection with the tank wall, with no dead spaces. This produces a simple hygienic process connection for the pH electrode for the first time. Horizontal installation is, therefore, preferred in all applications in the food industry. In dairies and other applications where cleaning-in-place and even sterilisation is frequently required, the sensor is often used with a connection, dairy fitting or clamp in the horizontal position.

Overhead installation

In special instances, such as the production of latex in high enamelled tanks, the sensor can be installed overhead, making pH measurement considerably easier. In this application it is necessary to clean and calibrate the electrodes at regular intervals, preventing the use of immersion assemblies suspended into the medium from above, while sensors can also not be applied from the side, since enamelling does not allow a process connection from the side. The only option is to install the sensor overhead where it can be automated at a reasonable cost.

Quick response times at negative temperatures

The device has already proved its reliability and accuracy in coolant monitoring. In addition, since IsFET does not need to undergo hydrolysis, its response time is generally quicker than with the glass electrode. This applies in particular at negative temperatures. Here, glass electrodes take several minutes to display the correct pH value, while the entire process with TopHit H takes a few seconds.

Measurements in non-aqueous solutions

Measuring the pH value in non-aqueous media has always proved problematic, as pH values vary according to the material, and because often glass electrodes cannot be used - without water a gel layer cannot form, and this is a requirement for pH measurement with glass electrodes.

For this reason processes were sometimes monitored manually using moistened pH paper. Yet, this was both time-consuming and costly, especially in biotechnology where even a millilitre of medium can be costly. TopHit H enables inline pH measurement for the first time in non-aqueous applications, and is already in use in aniline applications, as well as in the biotechnology industry.

The sensor can be stored in air

Because there is no gel layer on TopHit H, the sensor can be stored in air, where a glass sensor would become unusable. This makes it easier to maintain the sensor, especially in applications where you cannot be certain that the sensor is always in the medium, such as batch processes and fermentation.

No glass breakage

According to estimates, well over 10% of all electrodes are replaced due to accidental glass breakage during handling. The TopHit H break-resistant PEEK body is a safe alternative, and can spare replacement costs due to unintentional breakage. For this reason this sensor has inherited the conventional glass electrode's position in many applications.

Less calibrating

Due to the measuring principle applied in TopHit H, it usually requires less frequent calibration. The measuring and reference electrodes need to be calibrated in glass electrodes, whereas IsFET requires only the reference electrode to be calibrated.

Use in solutions with lower conductivity

With IsFET technology, the input impedance from the medium to the gate is extremely high (>10 to 12 Ω), enabling the sensor to be used in media with low conductivity. TopHit H is already used in demineralised water with low uS/cm values.

Long cable exposure

Because the electric circuit to the transmitter has a very low impedance, a long cable (up to 100 m) can be used for TopHit H. This negates the need for pre-amplifiers, as is the case with glass electrodes. Applications include the monitoring of the pH value in groundwater in deep springs.

New technologies allow for innovative measuring principles that present fresh benefits while previous drawbacks diminish or disappear. This is the case with TopHit H and the surrounding technology, which offers significant cost savings, as well as allowing inline measuring in previously impossible applications, such as those involving horizontal installation in hygienic applications.

For more information contact Grant Joyce, Endress + Hauser, 011 262 8000, [email protected], www.za.endress.com

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved