The ICoT 4300 provides intelligence for the control valve through a microprocessor-based system using the Hart protocol. Accurate measurement of valve stem position, input signal and actuator pressure can be recorded during normal operation, thereby providing information for control valve signature generation.

A standard handheld terminal (the Hart Communicator) may be utilised for field operations in conjunction with a remote PC for maintenance information and documentation.

A preventive maintenance and data logging system, in parallel with the 4-20 mA loops, performs on-line diagnostics of control valves with automatic record keeping for documentation purposes. The Hart communications capability of the ICoT positioner, coupled with the HPort multiplexer and Cornerstone control valve specific software, provides operating personnel the opportunity of implementing customised preventive maintenance programs. It additionally simplifies adherence to occupational health and safety requirements mandated by government regulations.

ICoT, with Hart protocol, provides an array of possibilities for improving efficiency and preventive maintenance procedures in many areas pertaining to control valve usage.

The Model 275 communicates with ICoT smart positioners via Hart protocol. Communication is accomplished by super-imposing a high frequency signal on top of the 4-20 mA output signal. This allows simultaneous communication and output without compromising loop integrity.

A single 4-20 mA ICoT positioner with up to two master devices may be connected to each Hart loop. The primary master is generally a management system or a PC while the secondary unit can be a handheld terminal or laptop computer.

A standard handheld Hart communicator is available for making field operations as uniform as possible. Manufactured by Rosemount, the Model 275 smart family interface functions as a common tool for Hart microprocessor-based field instruments. From any wiring termination point in the loop, the battery-powered Model 275 can perform diagnostic, configuration and interrogation functions. Additionally, while the 275 is off-line, configuration data can be stored for later downloading to one or more positioners. Simultaneous communication capabilities allow the handheld terminal to receive data from and send data to the positioner without disrupting the positioner's signal from the control room.

The devices have intrinsic safety certification from Cenelec/BASEEFA, Factory Mutual (FM), Canadian Standards Association (CSA) and Standards Association of Australia (SSA).

ICoT has also developed a smart positioner possessing the capability to predict rather than react to valve maintenance needs. With the ICoT positioner, operating personnel gain a realtime perspective on the state of control at the valve, including a view of operating integrity and emerging alert conditions. Timely information about each control valve's condition is made available to the plant's production and maintenance engineers.

Control valves are the most maintenance-intensive components commonly used in instrumentation and control systems. By inclusion of internal parameter sensing within the valve positioner, forewarning of the need for maintenance is made available with a comfortable degree of lead time.

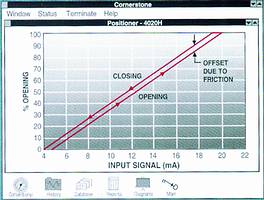

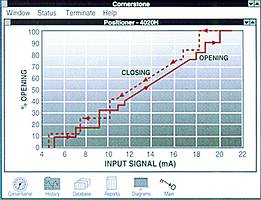

The following illustrates one of the early-warning diagnostic capabilities of the ICoT positioner. Figures 1 and 2 conceptually demonstrate the usefulness of tracking valve position versus instrument signal. Figure 1 depicts a small acceptable amount of offset between the opening and closing characteristics of a specific valve. The offset shown is the result of a degree of friction in the packing, guide bushings or plug and cage of the control valve. The extent of the offset is a function of the amount of friction and the actuator stiffness as determined primarily by spring constant, diaphragm area and air loading. If the valve is consistently being operated at approximately 50% open for an extended period of time, it is possible for deposits or corrosion to affect portions of the cage or stern not normally wiped by stroking. When the valve is called upon to stroke beyond these formerly established limits, these conditions will abrade the plug and cage surfaces causing excessive friction to be manifested as increased stroking force. Under such conditions, the dynamic versus static friction coefficients will differ sufficiently to cause jumpy operation and position overshoot. This is depicted graphically in Figure 2 where the effects of 'stick-slip' occur primarly at the end of travel. If sufficiently severe, the servo loop within the positioner will be unable to position the valve within an acceptable tolerance band and hunting will occur. This condition is usually preceded by symptoms detectable through the diagnostic capabilities of the ICoT positioner, thereby allowing for corrective measures to be taken and avoiding an unnecessary shutdown.

Combined with the Cornerstone software and the Hport multiplexer, ICoT has established an open platform for the commissioning, calibration and maintenance management of process control valves.

Valve & Automation

(031) 579 2593

(011) 397 2833

(035) 751 1458

| Tel: | +27 31 579 2593 |

| Email: | [email protected] |

| www: | www.valve.co.za |

| Articles: | More information and articles about Valve & Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved