Mitsubishi Electric has a 14,9% shareholding in Adroit Technologies, a privately held South African based company that develops world-class scada, alarm management and business intelligence software. With over 11 million frequency inverter drives already sold, Mitsubishi Electric has now introduced its latest generation of compact inverters, the FREQROL-CS80 series. In addition to better features and performance than its predecessors, the models are also more compact and easier to install. The improvements include a 57% reduction in volume, high performance, ease of use and easy maintenance. Together, these improvements make the FREQROL-CS80 an economical and versatile solution for a wide range of applications from wood processing to controlling fans and pumps.

Compact body

The compact size is achieved through a low heat generation design. Side by side installation of these inverters is possible as long as the surrounding air temperature does not exceed 40°C, allowing three FR-CS84-012-60 inverters to be installed in the same space normally required for two conventional models, which ultimately means space saving in the cabinet. A DIN rail installation attachment option is available for some models, but excluded for inverters FR-CS84-120 to 295.

High performance

Even with a 57% reduction in volume this inverter still offers high performance. Functions available include general-purpose magnetic flux vector control and auto tuning functions. These ensure that the inverters can be used in applications that require high starting torque, such as washing machines, agitators, and transfer machines, which include conveyors, hoists, and elevators.

There is also a brake unit connection which allows a brake to be connected using the available terminals. This is useful for applications that require regenerative braking torque during deceleration, such as transfer machines and food machines. When using the inverter with the brake unit, it is recommended the FR-CS84-050-60 or a higher capacity inverter is used.

Optimum excitation control continuously adjusts the excitation current to a level that provides the highest motor efficiency. For example, at 4% motor load torque for a general-purpose motor, the motor efficiency under optimum excitation control is about 30% higher than the motor efficiency under V/F control. Optimum excitation control is an option on this inverter where the excitation current is constantly adjusted to its optimum value to drive the motor most efficiently. With a small load torque, a substantial energy saving can be achieved.

Ease of use

These inverters have an easy to read operation panel with an optional LCD operation panel also available. This can be connected using the separate parameter unit connection cable via the operation panel connection connector. Another operation panel – the enclosure surface operation panel – enables inverter operation and monitoring of frequency setting from the enclosure surface.

The parameter unit FR-PU07 features helpful settings such as direct input with a 10-key pad, operating the status display and help function. Eight languages are supported and parameter settings for up to three units can be saved. A free trial version of the software configurator can be downloaded at the Mitsubishi Electric global website. This software contains start-up functions which allow for a shorter start time with easy setup. The software features the design and operability of all MelSoft Mitsubishi Electric products.

High-speed communication is supported using a controller and RS-485 connection. The inverter can also be controlled and monitored via a network. Using the Mitsubishi inverter protocol, Modbus RTU enables communication with a speed of 115 Kbps, which is faster than the 38,4 Kbs of conventional models.

Easy maintenance

There is a reduction in wiring check time since wiring can be checked simply by lifting the control terminal cover, which makes maintenance work easier. The control circuit terminals are spring clamp types to allow for easy wiring to the control circuit.

The main circuit terminals are screw types with easy wiring achieved by inserting the dedicated blade terminal of each cable. Without using the blade terminal, the loose wires can also be connected using a flathead screwdriver.

The spring clamp terminals provide high reliability since the internal terminal contacts are spring-type. Therefore, these wires can be protected against loosening or contact faults due to vibrations during operation on a bogie or during transport. They are also maintenance free since no additional screw tightening is required.

A specialised coating that conforms to IEC 60721-3-3 3C2/3S2 standards covers the circuit board to protect it in hazardous environments and for improved environmental resistance.

Supported applications

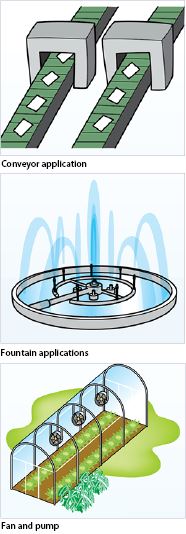

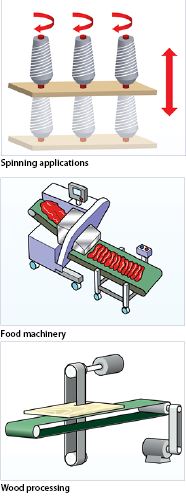

These inverters support a variety of functions that can be used in various applications.

Spinning: the motor decelerates to a stop without coasting when a power failure (or under voltage) occurs, allowing slack in the thread to be easily controlled. The traverse function, used for the traverse axis of the spinning machine, prevents uneven winding or collapsing.

Conveyors: conveyor belts can be controlled individually by using multiple inverters and automatic operation is achieved by collectively managing these multiple devices. The deceleration time can be reduced without using a brake resistor, allowing tact time to be reduced for a transfer line or equivalent. Since a smooth pattern is maintained from the present frequency to the target frequency, it is possible to reduce shock during acceleration or deceleration, thus preventing load shifts.

Fans and pumps: the flow rate and air volume are controlled by an inverter, which means it is possible to regulate these to pre-set levels. Optimum excitation control enables high motor efficiency, enabling energy savings in applications with variable load torque characteristics such as fans and pumps.

Food machinery applications: operation continues and the overcurrent alarm is not activated even if there is a sudden change in load, for instance during the cutting of food. General-purpose magnetic flux vector control means that, depending on the type of ingredients, the right amount of low-speed torque is possible to regulate a suitable speed for almost all types of food production. Since the motor decelerates to a stop without coasting when a power failure or under voltage occurs, dangerous situations are avoided during such situations.

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved