I have come across quite a few control loops that were doing a reasonable job of control and which were in fact completely unstable, and in some cases were working much better than if the loop had been tuned with normal robust parameters.

The most common example of unstable control that works well is of course On/Off control, which is used on processes with long lags, like many temperature processes, or on slow integrating processes like levels with very long retention times. An example of a typical temperature controller like this is a thermostat.

I have also often come across plant operators controlling fairly slow integrating processes in manual by opening and closing the valve between two limits to reverse the ramps. This results in the process having a limited cycle but staying within desired boundaries.

Another interesting example of unstable control working well was on a molasses flow loop in a carbon black plant. Molasses is a terrible sticky and viscous fluid to work with, and the plant technicians were having endless problems with the valve sticking. The loop was then tuned to give a small unstable cycle. This kept the valve moving continuously and prevented it from sticking. Quite ingenious!

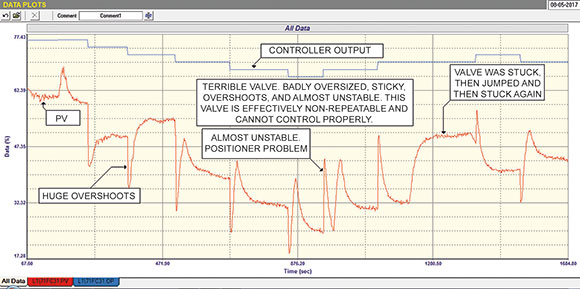

I recently came across a very interesting example of a flow loop that was only able to work because it had completely unstable tuning. The loop was the reflux flow on a distillation column, and this is an important flow as it is used as the cascade secondary for the column top temperature control. Figure 1 shows the open loop test on the valve.

It shows the following major valve problems:

• It is about seven times oversized, which is very bad for control as oversized valves magnify all the control problems by the oversize factor.

• The valve and positioner combination is working very badly. There are huge overshoots and undershoots on step changes, and at times it seems as if the positioner is actually slightly unstable.

• The valve also appears to be quite sticky, and at times it suddenly jumps to a new and often incorrect position where it sticks.

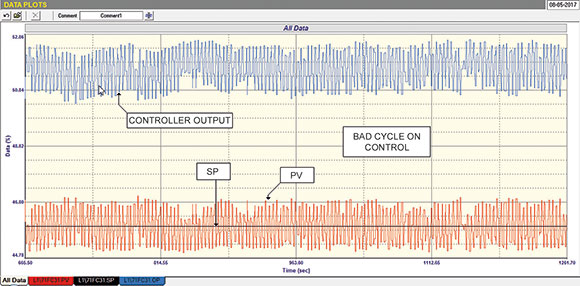

These factors effectively make the valve very non-repeatable, and it would not really be possible to get any reasonable control with normal robust tuning. However, the person who had tuned the loop had done a very clever thing. He had inserted a very high proportional gain, and a relatively slow integral. The high gain made the loop unstable, and resulted in a small amplitude continuous cycle. The integral was fast enough to keep the process near setpoint.

Figure 2 shows a closed loop test with a constant setpoint. The resultant performance is good enough for to allow good control on the column temperature. Obviously this is not the ideal, as one wonders how long the valve will last, but it does work. (Many plants like refineries may not have bypass valves on the control valves, and hate having to shut down a process to work on a valve.)

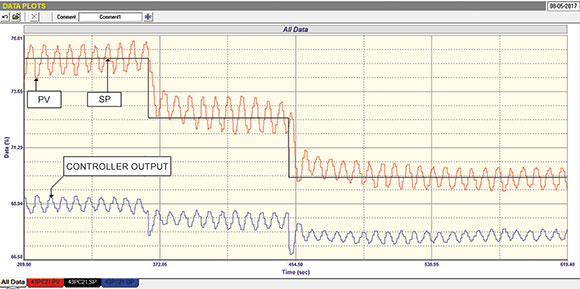

Another example of unstable tuning working quite well was on a gas pressure control loop on a furnace, also in a petro-chemical refinery. Figure 3 shows the loop cycling continuously with unstable tuning, but following setpoint changes reasonably well and quickly.

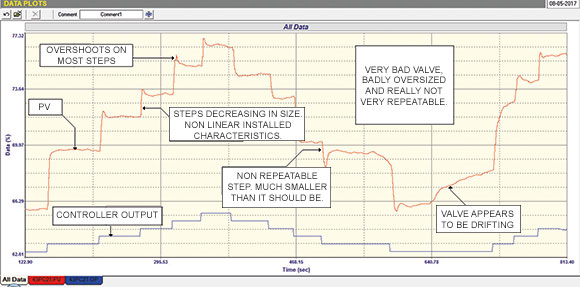

Figure 4 shows the open loop test. There is a problem with the valve/positioner combination. There is quite a bad overshoot on step changes, an indication of negative hysteresis. Other problems are that the valve is probably several times oversized, and that there is non-linear installed linearity, with process gain increasing as the process moves down. Trying to control this valve would really cause difficulties.

I think the person who optimised the loop deliberately tuned it to be unstable, so that the valve is continuously forced to operate in a small band around the correct position, and it worked well.

So maybe instability is sometimes not too bad!

Michael Brown is a specialist in control loop optimisation with many years of experience in process control instrumentation. His main activities are consulting, and teaching practical control loop analysis and optimisation. He gives training courses which can be held in clients’ plants, where students can have the added benefit of practising on live loops. His work takes him to plants all over South Africa and also to other countries. He can be contacted at Michael Brown Control Engineering cc, +27 (0)82 440 7790, [email protected], www.controlloop.co.za

| Email: | [email protected] |

| www: | www.controlloop.co.za |

| Articles: | More information and articles about Michael Brown Control Engineering |

© Technews Publishing (Pty) Ltd | All Rights Reserved