In 2006 Imana Foods recognised the need to acquire official HACCP accreditation. It looked to system integrator IT Dynamics to provide a solution that would contribute to achieving this goal.

Wonderware’s PEM was first implemented in 2009 resulting in a solution that enabled the following:

* Systematic traceability of raw materials consumed during the blending stage.

* Improved control of the blending operation by displaying the appropriate recipe step-by-step.

More recently, the solution was expanded to add visibility to the packing process. Industrial panels were installed to control the work orders and display a real-time case count to the operators. This implementation required that Wonderware’s PEM be integrated with the ERP system to ensure that all work order information was stored accurately. With the advancement in Wonderware’s solution offering, a migration became necessary.

Implementation

Invensys Wonderware staff were consulted and, in collaboration with IT Dynamics and Imana Foods, it was agreed that Wonderware would compile the necessary documentation, considering all the information that was gathered in workshops with IT Dynamics and Imana Foods. IT Dynamics would then develop and implement the solution.

Workshops were held to address the following:

* Define the project objective, business context and purpose.

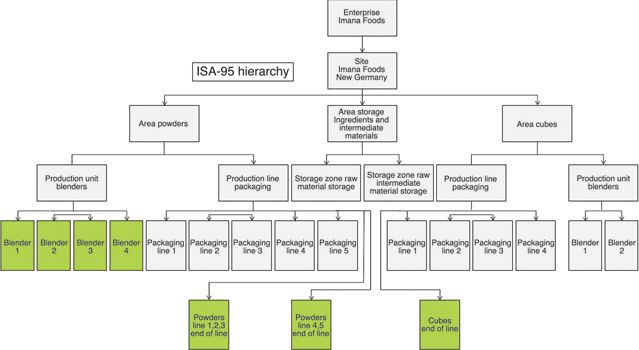

* Understand the process plant model for Imana Foods in accordance to the ISA-95 standard (Figure 2).

* Determine which modules of the MES solution to implement.

* Analyse the activities of the different production centres with reference to the relevant activity models.

* Define the reporting and visualisation requirements.

The project goals included:

* Upgrading the legacy PEM software to the MES v4 software.

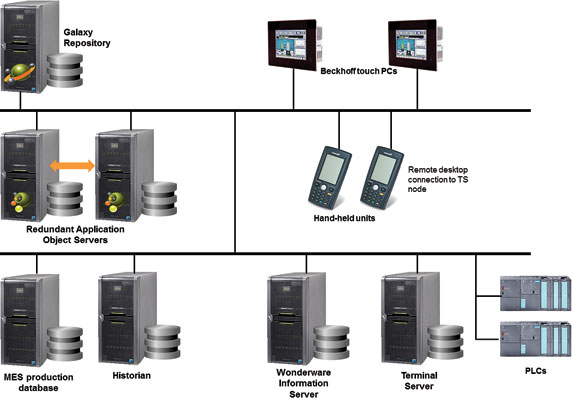

* Redesigning the blender traceability application infrastructure, making it more stable and requiring less support.

* Migrating the Wonderware hardware to a virtual platform.

* Providing Imana Foods with a solution that would minimise system downtime should there be a system failure.

“The project was originally designed for one blender and one handheld scanner using Wonderware’s Production Event Module,” says Murray Irvine, project engineer, IT Dynamics. “But this escalated to multiple units and their interactions became very complex. The system needed to be far more dynamic, hence the need to redesign from scratch, but this time using Wonderware’s MES Operations 4.0 which provided the required extra functionality.”

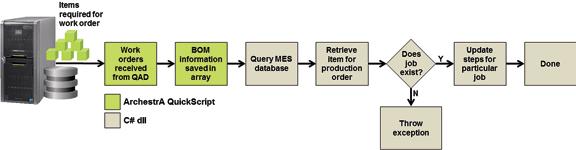

The implementation took just under 16 months which included five months of development time. To facilitate and simplify the cutover process from the old system to the new, IT Dynamics implemented virtual hardware in the form of VMWare servers. As with many projects, the implementation faced a big challenge: integrating the MES and the ERP. This required the team to develop custom C# dll script function libraries that utilises the MES API to transfer data between the MES and the ERP. The custom development has resulted in the ability to capture recipe and work order data into both the MES and ERP, and more importantly, to ensure that the correct recipe step is displayed to the operator.

“In my opinion, the most outstanding feature of the implementation was the high level of data transfer integration we achieved between the MES and ERP systems,” says Irvine.

For the blending operation, the MES queries the ERP for all the relevant work order details, including the bill of materials, specifications and of course the recipe, as soon as the work order is released for production. The data received is then dynamically added to the MES database to enable production to continue.

“All the master data was kept in the ERP system and the MES pulls the information when necessary and writes any data required by the ERP back during the blending process,” says Irvine. “Depending on the specific work order status, both systems know at all times the progress of the job in the blending process.”

Irvine maintains that having key Imana Foods stakeholders on site during Go-Live was critical to ensure that any information transfer between the SI and the end-user was delivered in a timely manner. Furthermore, having a Wonderware consultant on site during this critical period meant that any problems were dealt with efficiently.

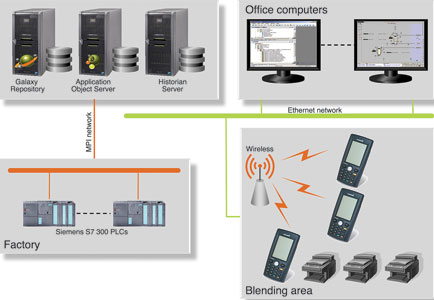

The Invensys Wonderware solutions implemented to accomplish the goals are System Platform 2012, InTouch 2012 Scada/HMI, MES v4.5, Historian, Wonderware Information Server 2012, DASSIDirect 3.0 and Hotfix.

Business benefits

* By utilising both VMWare and Wonderware Automation Object Server (AOS) redundancy, Imana Foods is operating on a hardware platform that minimises system downtime should there be a failure.

* The company can now benefit from all of the present and future features and functionality that MES v4 has to offer.

* The platform is more stable requiring less operational support.

* Implementation is aligned to the IT business road map of utilising virtual technologies.

* The platform enforces standardisation of processes.

For more information contact Jaco Markwat, Invensys Operations Management, +27 (0)11 607 8100, [email protected], www.iom.invensys.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved