The industrial revolution occurred because producers realised that many craftsmen collaborating together were far more efficient than individual craftsmen working as individuals. This breakthrough insight is the foundation of modern industrial automation. But further breakthroughs in efficiency and collaboration are still possible, and a new revolution is occurring in industrial automation. Today, industrial automation operators are discovering that by integrating disparate data control, process management, security, surveillance, and other automation systems, it is possible to achieve even greater heights of efficiency, safety and quality.

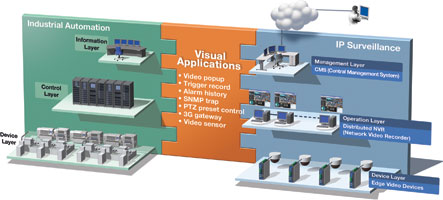

System convergence is a modern revolution in industrial automation, made possible by the convergence of many automation systems onto a single industrial Ethernet infrastructure. Moxa’s comprehensive industrial Ethernet solutions are key building blocks upon which industry is achieving system convergence that creates seamless connectivity and collaboration among automation systems. Instead of dividing attention between multiple systems, automation operators can now focus their attention on a single unified interface. Convergence also allows disparate subsystems to share data and collaborate to optimise performance.

Two case studies will show a detailed breakdown of how Moxa fulfils the bandwidth, security and management requirements that enable industry to harness the full potential and operational benefits of automation convergence.

Case one: Scada surveillance convergence

In oil and gas operations, remote pipelines are monitored through two systems: a real-time I/O system, typically managed through a scada, and video surveillance, typically managed through a separate CCTV system. There’s little room for error when managing a lucrative pipeline, so every second counts when responding to critical events such as I/O alerts. Integration of scada and video systems would allow system operators to connect scada events to relevant video footage thus increasing situational awareness of remote pipeline conditions.

Challenges

The network that integrates the scada and video systems must be robust enough to work across a long-distance oil pipeline in varied and demanding outdoor conditions. The system integration itself must be seamless so that it does not create more headaches than it solves; the two systems must be integrated to such a degree that system operators can use them together without a second thought and immediately react to scada events without wasting time looking for video footage.

Solutions

Moxa’s solutions have excelled in pipeline applications and the integration of scada and surveillance systems on robust Ethernet network infrastructure. The hardware solutions are rugged and field-tested in the most demanding of conditions, and OPC-based solutions or optional visual control objects make it easy to integrate scada with video surveillance. Using Moxa technology, the Scada/HMI interface can immediately display pop-up surveillance video once a scada alarm is triggered.

Bandwidth considerations

As video surveillance applications expand in size and require higher resolutions, it becomes imperative that video traffic management and network resource allocations are at optimal levels to avoid network congestion. Network scalability for future expansion requirements is also an important factor to consider when planning surveillance deployment.

Identifying the type of video surveillance that is required can help to determine the amount of bandwidth and storage that will be needed for the surveillance network. The three service classifications of video applications: real-time observation (live monitoring), forensic review (event recording), and recognition (intelligent video analysis), each have different network resource demands that will directly impact bandwidth and storage requirements. It is possible for a video surveillance system to require more than one service classification type, which will require additional network resources.

Advantages of convergence

With scada and surveillance integration, operators can simultaneously monitor both scada status and even triggered surveillance video, including live video and pre-event footage. Moxa’s Gigabit solutions and bandwidth optimisation technologies ensure that the converged network will reserve priority bandwidth for critical I/O or video transmissions, so that the two systems will not affect each other’s functionality. With scada surveillance convergence, the remote monitoring of oil pipelines is far more efficient, productive and secure.

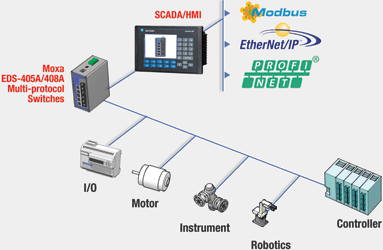

Case two: PLC network convergence

Traditional fieldbus networks were, and some still are, isolated automation systems which require extensive local monitoring and routine onsite maintenance. To increase productivity and reduce operating costs, many manufacturers and plant operators have deployed industrial Ethernet to converge remotely isolated fieldbus systems for centralised control and monitoring.

Industrial Ethernet technology consists of various Ethernet-based protocols, developed with deterministic capabilities as robust alternatives to costly proprietary automation systems and, more importantly, enable a highly-scalable and unified infrastructure to converge all network nodes at the administrative, control, and field levels. Many advanced industrial automation systems have deployed gateways to bridge fieldbus I/O devices to Ethernet based PLCs and switches to connect PLCs and scada terminals at remote control centres to reduce operating costs and improve production efficiency of expanding automation networks.

An Ethernet-based single network infrastructure offers operators the efficiency of centralised network management with greater network scalability and flexibility, higher bandwidth availability and faster failure recovery. To optimise system performance and improve network manageability, switches and gateways should integrate seamlessly with industrial automation networks for centralised scada control and monitoring. However, integrating industrial fieldbus with industrial Ethernet presents integrators and engineers considerable challenges.

Challenges

Many distributed automation systems use fieldbus protocols developed for use with specific PLC control systems. To create more efficient control and monitoring, automation systems need to consolidate diverse PLC networks into one centralised platform for all-in-one management.

Many PLC vendors have helped their control devices transition to deployment on Ethernet networks by adopting Profinet and EtherNet/IP. PI has developed Profinet as an Ethernet-compatible form of Profibus that can be transmitted over an Ethernet network, and the ODVA has developed EtherNet/IP specifically for use with industrial Ethernet.

Solutions

Moxa’s industrial Ethernet managed switches and gateways offer smart features that enable configurable network intelligence and seamless interoperability with EtherNet/IP, Profinet, and Modbus TCP/IP. Automation engineers can easily add these fieldbus compatible switches and gateways into Rockwell’s RSLogix or Siemens’s Step7 scada systems, which then allow the PLC/HMI to recognise and manage the registered network devices.

Advantages of convergence

Thanks to an integrated system, factory floor engineers can focus on a single scada interface. From this single control centre, it is possible to access control and network devices, perform system-wide data analysis and identify how best to optimise system performance. Thanks to Moxa’s EtherNet/IP and Profinet support and multi-protocol switches and gateways, system integrators have greater flexibility to deploy devices and do not need to worry about how to achieve cross-network integration.

Mb>How Moxa enables automation convergence</b>

For any industrial network, Moxa’s solutions include unique technologies and features that help make network convergence less complicated, allowing system operators to focus on harnessing the benefits of more tightly integrated automation systems and not on the headaches of systems integration.

The case studies outlines above highlight how Moxa’s bandwidth management and video and fieldbus integration features make network convergence easier to accomplish. Moxa’s industrial Ethernet solutions are packed with the redundancy, performance, security and ease-of-use features that empower converged automation networks.

* Performance: high density 10GbE/Full GbE capability for future-proof applications.

* Availability: milliseconds fast resilience for non-stop operations.

* Security: rigid access security across physical and virtual networks.

* Manageability: easy to use from configuration, to management, to diagnostic maintenance.

* Interoperability: versatile fieldbus technologies for automation networks collaboration.

* Reliability: proven reliability for productivity and profitability.

| Tel: | +27 11 781 0777 |

| Email: | [email protected] |

| www: | www.rjconnect.co.za |

| Articles: | More information and articles about RJ Connect |

| Tel: | +27 11 548 9960 |

| Email: | [email protected] |

| www: | www.profiafrica.co.za |

| Articles: | More information and articles about PI SA (PROFIBUS & PROFINET SA) |

© Technews Publishing (Pty) Ltd | All Rights Reserved