Fieldbus systems are used in all areas of process automation due to their high level of reliability. Nevertheless, faults can still occur, even in the reliable communication via fieldbus. In studies spanning several years, Pepperl+Fuchs has investigated exactly what typical fault scenarios look like and what specific measures protect against them.

Knowing causes of failure enables effective prevention

Common faults include voltage spikes caused by lightning strikes. Other typical fault scenarios include a slow change in the signal level as a result of the ingress of moisture or contact bounce.

If, for example, a cable is pulled through the cable gland when replacing a device during ongoing operation, this may cause a short-circuit bounce. If these highly dynamic electrical faults occur only very briefly, then only individual fieldbus telegrams are affected – because the repetition of the data transfer is defined in the protocol, a fault of this kind has no consequences. However, if the bounce continues over a longer period, communication errors may occur in multiple devices. In the worst case scenario, faults of this kind can cause the entire system to be inadvertently switched off.

However, Pepperl+Fuchs investigated more than just these typical scenarios. The aim was also to find faults that are less likely to occur. Even if plant operators do not really expect such incidents, it is crucial to provide the ability to handle them. This is the only way to ensure maximum plant availability.

The intelligent fieldbus installation

A more reliable way of managing these fault scenarios is to adopt a forward-looking and automated approach to handling faults through intelligent installation. Using fault-tolerant technology, the fieldbus infrastructure adapts itself to the actual requirements that arise in day-to-day operation. For the user, this means maximum convenience when replacing devices, without any additional measures being required and without the risk of a segment failure.

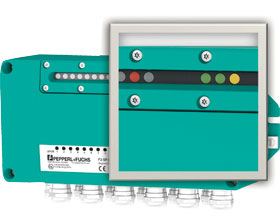

An important component of this type of intelligent fieldbus installation is the diagnostics-enabled FieldConnex device coupler, the latest generation of which has been specially developed to proactively detect and isolate faults before they can lead to a failure. In this way, the devices ensure that the plant is protected against many of the faults mentioned. Using these device couplers also means that users can ensure that maintenance work on the installation does not have a negative impact on plant operation.

FieldConnex device couplers recognise the special dynamics of signals caused by contact bounce or vibrations from loose contacts and can distinguish these from regular fieldbus signals. This enables them to find and isolate typical defects occurring in the installation. The affected output is temporarily switched off to protect the fieldbus communication against faults.

Even elusive temporary faults, such as a declining signal level caused by the ingress of rainwater, can be detected and isolated in this way. The physical layer is monitored in the most effective way possible, avoiding time-consuming troubleshooting and clearly increasing plant availability.

The new highly intelligent components

The new FieldConnex FieldBarrier (R4D0-FB-IA) allows monitoring of the fieldbus physical layer at each FieldBarrier output. This enables gradual changes in the installation and faults in the control room to be reported. This monitoring function ensures an even higher degree of transparency and covers a significant gap in the monitoring process as it proactively identifies maintenance requirements.

A key innovation is the sophisticated FieldBarrier load management function. The 12 outputs start sequentially, reducing the load on the power supply from the inrush current. If the segment current reaches critical levels, automatic load-shedding of less critical nodes is activated to safeguard against failure of the entire segment.

The FieldConnex segment protector can also detect and isolate faults progressively. This makes it a key element in any intelligent fieldbus installation in Zone 2 or in areas without explosion protection. The new, revised version (F2-SP-IC), available in compact aluminum housing is ideal for use in confined spaces.

A new LED concept also gives advantages in terms of plant safety and convenient handling: As a result of the new housing design, the status LEDs are visible from the outside at all times. This enables fast diagnostics at a glance and saves both time and costs when it comes to on-site maintenance.

Both FieldConnex device couplers operate entirely independently and with no configuration required. They are the perfect complement to the range of diagnostics-enabled intelligent fieldbus components, and the innovative features are another important step on the path towards the ideal of absolute availability.

For more information contact Mark Bracco, Pepperl+Fuchs, +27 (0)87 985 0797, [email protected], www.pepperl-fuchs.co.za

| Tel: | +27 10 430 0250 |

| Email: | [email protected] |

| www: | www.pepperl-fuchs.com/en-za |

| Articles: | More information and articles about Pepperl+Fuchs |

© Technews Publishing (Pty) Ltd | All Rights Reserved