Belden creates breakthrough network solution for oil refinery

August 2014

Fieldbus & Industrial Networking

Dexter System Solutions is an operations and solutions integrator for the industrial process industry. The company has built a global reputation by producing mission-critical networking solutions for the oil and gas industry, within a wide array of hazardous environments according to the latest safety requirements such as ATEX, IEC-Ex and NEN.

To meet the needs of one of the world’s largest petrochemical companies, Dexter Solution Systems and Belden were asked to provide a redundant industrial Ethernet and WLAN network according to IEC 61850 specification for an oil refinery location. This would require explosion-proof certifications (UL and ATEX) and shipboard approvals (ABS and DNV) and would have to provide a high level of industrial security.

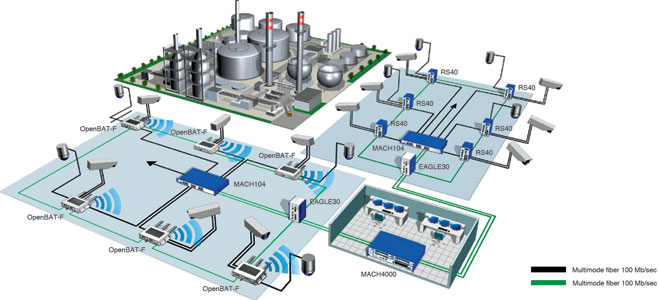

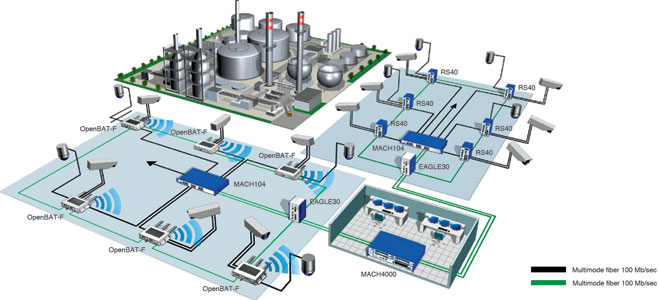

Using Hirschmann RSR(S) and OpenBAT-F combined with ruggedised industrial backbone switches Hirschmann MACH1040 and Hirschmann MACH4000, Belden and Dexter were able to deploy a comprehensive and redundant WLAN and Ethernet Parallel Redundancy Protocol (PRP) solution that could withstand the rigorous environment and strict standardisation requirements commonplace within the oil industry. This PRP was created in accordance to series DIN EN/IEC 62439. PRP is relatively new in Ethernet via the RSP. PRP executed over WLAN via the RSPS is a breakthrough development. Both networks are managed centrally via their own devoted Hirschmann MACH1040 switches. In addition, both networks are connected centrally to the plant control room and managed by the Hirschmann MACH4000 switch. Industrial security is provided by the EAGLE30; segmenting each independent network into subnets. For the first time, networks are able to guarantee uninterrupted data communication over WLAN and Ethernet.

System requirements

This project required stable and reliable wireless links because:

* Video is transmitted, demanding high bandwidth.

* Safety of information technology equipment needs to be EN 60950.

* Transmission rate is 450 Mbps according to IEEE 802.11n for WLAN network.

* Operation temperature is between -40°C to +70°C.

* High Availability Ethernet is required in accordance with IEC 62439.

* A multimode fibre optic network is applied.

* Certification for Atex Zone 2 hazardous environment is required.

The Belden solution

Adjacent redundant fibre optic rings support Parallel Redundancy Protocol (PRP) over two separate networks; one industrial WLAN (OpenBAT-F) and one industrial Ethernet (RS40). Both networks are managed centrally via their own devoted Layer 2 industrial 19-inch workgroup switch; the Hirschmann MACH1040. Both networks are connected centrally to the plant control room and managed by Hirschmann’s Layer 3 industrial backbone switch; the MACH4000. Industrial security is provided with the EAGLE30; segmenting each independent network from the control room. Because BAT devices with Atex Zone 2 certification do not require external housing, they are lightweight and easy to mount.

Belden and Dexter System Solutions were able to meet the customer’s wireless and Ethernet network demands with a minimalist solution that surpassed the competition in redundancy features, technical capability and overall cost-effectiveness. The Belden solution also provided the customer with access to network design and integration support.

For more information contact Greg Pokroy, Jaycor International, +27 (0)21 447 4247, [email protected], www.jaycor.co.za

Further reading:

Suppression and safety solutions for fire and gas in mission-critical industries

Fieldbus & Industrial Networking

By representing world-leading brands and focusing on fully integrated, certified systems, HMA South Africa is positioning itself as a trusted partner in fire detection, suppression and explosion-proof safety solutions across the continent.

Read more...

Integrating fire alarm systems into building management systems

Beckhoff Automation

Fieldbus & Industrial Networking

Fire alarm systems work independently of the building automation system. Schrack Seconet has developed a flexible gateway using ultra-compact industrial PCs and TwinCAT from Beckhoff, which can be used to flexibly convert a customer-specific communication protocol to a wide range of transmission standards.

Read more...

Premium unmanaged industrial switch

Vepac Electronics

Fieldbus & Industrial Networking

Premium unmanaged industrial switch for long-distance, noise-free fibre connectivity

Read more...

Fire and gas suppression solutions for mission-critical industries

Fieldbus & Industrial Networking

By representing world-leading brands and focusing on fully integrated, certified systems, HMA South Africa is positioning itself as a trusted partner in fire detection, suppression and explosion-proof safety solutions across the continent.

Read more...

The future of manufacturing

Fieldbus & Industrial Networking

Industrial automation is evolving at an unprecedented pace. At the forefront of this transformation is the Siemens SIMATIC ET 200SP HA Distributed I/O system. This is a flexible and scalable distributed I/O system for modern signal transfer from the field to the control level.

Read more...

Time-sensitive networking

RJ Connect

Editor's Choice Fieldbus & Industrial Networking

In this article, we will explore what is driving the rise of time-sensitive networking, how it is reshaping industrial efficiency, the challenges when deploying this technology, and ways to tackle these challenges.

Read more...

Loop Signature 30: Nonlinearity in control loops (Part 1)

Michael Brown Control Engineering

Editor's Choice Fieldbus & Industrial Networking

If nonlinearity occurs it means that if one is to carry on controlling with the same response to changes in load or setpoint, then the tuning of the controller will also need to be adjusted to meet the new conditions.

Read more...

PC-based control regulates innovative dehumidifiers

Beckhoff Automation

Fieldbus & Industrial Networking

Swedish company, Airwatergreen is breaking new ground in the dehumidification of air in industrial buildings and warehouses. The patented CVP technology reduces energy requirements and ensures an indoor climate that prevents corrosion and mould growth. PC-based control from Beckhoff regulates this innovative process.

Read more...

Ethernet connectivity for embedded systems

Fieldbus & Industrial Networking

Delivering Ethernet connectivity for embedded systems, XPort ETH Click is a compact add-on board from MIKROE, the embedded solutions company that dramatically cuts development time by providing innovative hardware and software products based on proven standards.

Read more...

Compact mini PC

Vepac Electronics

Fieldbus & Industrial Networking

AS AAEON’s first Intel Core-powered PICO-SEMI system capable of fanless operation, the PICO-MTU4-SEMI from Vepac Electronics is easily deployed as part of larger equipment setups or integrated as the central unit of smart robotics solutions such as AGVs, AMRs and drones requiring minimal maintenance.

Read more...