In mining operations, the quest for efficiency and productivity is key. Challenges such as declining ore grades, market volatility and optimising separation processes such as leaching, flotation and thickening emerge are important focus areas. Recent studies, including research conducted by McKinsey, highlight the huge productivity loss of 35% experienced by mining operations globally between 2004 and 2014.

This underscores the urgent need for innovative solutions to enhance the performance of extraction processes while balancing operational costs and environmental impact.

The complexity of mining separation processes

Leaching, flotation and thickening represent essential stages in the extraction of valuable minerals from ore deposits. However, achieving optimal separation efficiency is no small feat due to the intricate interplay of numerous variables. These processes involve the use of chemicals, a significant cost driver, and often entail substantial water consumption, posing sustainability challenges in water-scarce regions.

Leaching: Extracting value with precision

Leaching involves the extraction of metals from crushed ore using acid solutions, with the choice of acids dependent on ore characteristics. Precise control of acid concentration and irrigation flow rates is critical for optimal leaching outcomes. Endress+Hauser’s expertise lies in providing tailored instrumentation solutions to optimise leaching processes. With our advanced digital analytical sensors, we enable accurate monitoring of key parameters, ensuring reliability even in harsh chemical environments. By minimising process downtime and optimising acid usage, our solutions empower operators to enhance leaching efficiency and maximise resource recovery.

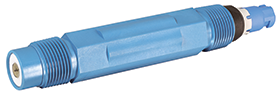

The Memosens CPF81E pH sensor offers ideal support for pH measurement in these demanding applications. Its flat membrane is suitable for abrasive media and our patented electrolyte bridge provides enhanced protection against electrode poisoning.

Easy sensor installation is ensured with threaded connections on both ends and a robust polymer housing. The versatile Liquiline CM442 transmitter, with advanced diagnostic functionalities via Heartbeat Technology, ensures maximum process integrity. Optionally, the immersion assembly Flexdip CYA112 can be upgraded with a cleaning nozzle for automated cleaning operations, making the measuring point futureproof according to your needs.

Froth flotation: Maximising recovery through advanced measurement

Froth flotation plays a key role in recovering fine mineral particles, particularly in platinum, gold and copper mining. This process relies on various parameters, including flow and density measurements, pH levels, chemical dosing and air flow rates, all of which significantly impact separation efficiency. Our comprehensive suite of instrumentation solutions is designed to address the diverse needs of froth flotation operations. From electromagnetic flowmeters for precise feedstock measurement to digital analytical sensors for real-time pH monitoring, our portfolio enables the seamless integration and optimisation of flotation processes. By leveraging advanced technologies such as ultrasonic sensors and Coriolis flowmeters, operators can achieve enhanced control over key process variables, maximising mineral recovery while minimising resource consumption.

Embracing innovation for sustainable mining

Today, achieving more with fewer resources is crucial, so improving mining separation processes is very important. By harnessing the power of precision instrumentation, mining companies can achieve significant improvements in separation efficiency, productivity and sustainability. Endress+Hauser’s comprehensive portfolio of advanced measurement solutions stands ready to empower operators with the tools they need to navigate the complexities of modern extraction processes and unlock maximum value from their mineral resources. As the mining industry continues to evolve, embracing innovation will be key to ensuring its long-term viability and sustainability.

Collaborating for success

Collaboration with industry experts, including equipment suppliers and technology providers, can further enhance the effectiveness of mining separation processes. By leveraging external expertise and embracing a spirit of innovation, mining companies can access cutting-edge solutions and best practices to drive continuous improvement and sustainable growth.

Optimising mining separation processes requires a multifaceted approach that integrates precision instrumentation, advanced technologies and collaborative partnerships. By embracing innovation and consulting with experts, mining operations can achieve greater efficiency, productivity and sustainability, ensuring long-term success in the changing global environment.

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved