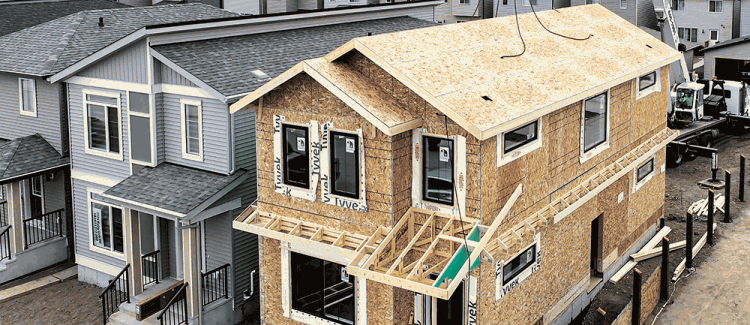

Imagine a world where affordable, sustainable housing isn’t a dream, but a reality. This vision faces two significant hurdles: skyrocketing construction costs and a shortage of skilled labour.

Based in Edmonton, Alberta, Promise Robotics is bringing the most intelligent, flexible and compact industrial robotic systems to the construction industry. The industrial solution is powered by a cloud-based software platform that manages the entire production lifecycle from planning to factory floor operations, scheduling and logistics. With the factory-as-a-service concept, homebuilders can expect to dramatically reduce the time for final onsite assembly of homes by up to 70% compared to traditional methods. For example, a single-family home could be assembled in about five hours and a 64-unit, three-story apartment building in just two weeks.

“Automation is not very common in the construction industry, which remains heavily labour-intensive,” said Ramtin Attar, CEO and co-founder of Promise Robotics. “Our goal is to build foundational technology – an automation system with a tangible return on investment and without limits for wide market adoption.”

Challenges in robotic homebuilding

Developing these innovative construction systems presented unique challenges. A primary hurdle was the need for a robust, high-performance control system. Specifically, real-time processing was crucial for precise robot control with position feedback.

“One of the key lessons we’ve learned is how to use perception to handle material variations that can occur during production,” explains Farid Mobasser, director of software at Promise Robotics. “We have to provide feedback to the robots and adapt to unique scenarios that might disrupt the process. It’s a continuous learning curve – we test and build different structures, and shapes, and handle edge cases to improve our systems.”

Another key challenge was ensuring a compact, integrated system design. Minimising wiring and complexity was essential for facilitating quick deployment in a dynamic construction environment with limited space.

A solid foundation using EtherCAT and PC-based control

To address these challenges, Promise Robotics leveraged several Beckhoff products, including TwinCAT 3 automation software and EtherCAT for data transmission between controllers, drives and I/O components. TwinCAT offers an end-to-end engineering and runtime platform for all automation functionality, from machine control logic and motion control to safety and HMI. The TwinCAT development environment allows Promise’s engineers to leverage a wide range of programming languages including structured text, ladder logic and C++ to rapidly build robust applications.

EtherCAT can handle real-time communication with minimal latency – a critical requirement for precise robotic control. The high-performance fieldbus seamlessly integrates motion control, safety functions and other machine components with high data rates, enabling the complex construction systems to operate smoothly in dynamic operation.

“The flexibility and scalability of EtherCAT was a big factor. It’s the fastest industrial Ethernet communication protocol and Beckhoff also offers a wide complement of hardware. This includes everything from the CX2043 Embedded PC to I/O components and all drive technology, including motors, drives and cables,” says Darren Brix, director of hardware at Promise Robotics. “It’s a turnkey package that streamlines process and system design. EtherCAT really makes it simple and efficient to complete a harmonised, consistent industrial solution at a high standard.”

The CX2043 Embedded PC from Beckhoff, featuring a quad-core AMD Ryzen CPU with a clock speed of 3,35 GHz, is the powerful backbone of the control system, allowing seamless integration with all Beckhoff I/O components. Paired with TwinCAT automation software, the CX2043 becomes a high-performance PLC and motion control system, supporting both 32-bit and 64-bit modes, and providing high processing power with the short cycle times needed for precise, deterministic control in this dynamic environment. A CP3924 multi-touch control panel, leveraging the one cable technology CP-Link 4 for connection to the PC, serves as the main interface for operators to control the robotic systems.

Dynamic motion with distributed drive systems

Precise control of the robotic arms and actuators is achieved using the compact, integrated Beckhoff AMI8122 servo drives which combine the servomotor, output stage and fieldbus connection in a space-saving design. Promise Robotics leveraged the integrated servo drive to build a custom end effector paired with a KUKA robot to achieve the precision alignment required to build different structures, shapes and sizes. The AMI8122 is part of Beckhoff’s distributed drive solutions, which bring drive technology out of the control cabinet and place it directly on the machine. This design significantly reduces the control cabinet size, overall machine footprint and cable length, making it ideal for dynamic construction environments.

The high-speed EtherCAT communication protocol and TwinCAT 3 Drive Manager 2 also simplify implementation and commissioning in real-world construction scenarios. Because safety is paramount, the EL6900 TwinSAFE component ensures the safe operation of all machines. This system-integrated EtherCAT Terminal with TwinSAFE Logic handles safety-oriented applications based on Boolean values, with function blocks for processing safe input signals and generating safe output signals. Additionally, it supports up to 128 safe connections and includes a backup and restore function for easy controller exchange, contributing to the reliability and safety of the solution.

A blueprint for the future

By standardising their control system on automation technology from Beckhoff and relying on the flexible and open EtherCAT fieldbus system, Promise Robotics has significantly accelerated research and development cycles and reduced commissioning times. The standardised approach simplifies maintenance, ensures consistent operation across all machines and allows seamless integration of new innovations, reducing downtime and increasing productivity.

“Right now, we’re focused on wood frame construction, which is about 80% of residential construction in the USA and Canada. But essentially, we are building the largest AI library for robotic assembly tasks that could be extended to all kinds of building assemblies,” Attar says, explaining the challenges involved in attempting to transform an entire industry. “There’s a reason why automation has not scaled in this massive, multi-trillion-dollar industry. While there have been some successful custom implementations, scalability and rapid deployment have been rather limited. Our goal is to deploy these systems very rapidly in non-custom factories, where you can take over a warehouse, turn on the lights, and start returning profit on your capital.”

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved