Freybadi, one of the largest chocolate manufacturers in Indonesia and a trusted supplier of chocolate in the Asia-Pacific, Middle East and African regions, has adopted the Siemens Xcelerator portfolio of industry software to optimise its manufacturing and production processes. “Our large production capability and flexibility enable us to meet the demands of the chocolate industry at various scales, from micro to multinational, and we needed a solution that would support us in optimising our production schedules. Our work with Siemens and Opex Consulting Group has allowed us to transform our production scheduling digitally and maintain the agility we need to serve our customers,” said Adi Christian, Freyabadi project and engineering manager.

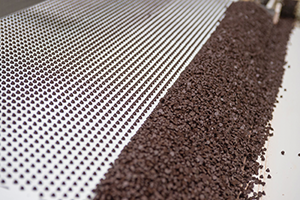

Freyabadi manufactures chocolate, sourcing the cocoa raw materials from reputable producers in Africa, Asia and South America to create the flavour profile desired by its local consumers. It currently manages over 1500 SKUs, from raw material to finished goods, and needed a comprehensive scheduling solution that could cater for its complicated process parameters and help to accommodate sudden changes – alongside a requirement for a digital batch record of raw material usage, integrated with its ERP system.

To help overcome these challenges, Freyabadi has adopted Opcenter Advanced Planning and Scheduling (APS) software from Siemens to enhance its production scheduling, citing the driving factor as the built-in changeover algorithm that helps the company minimise change over time and increase production capacity. It has also adopted the Mendix low-code platform to automate its data collection during chocolate production, helping to ensure that the data is synchronised between Opcenter APS and the company’s ERP system.

“We’re thrilled to support Freyabadi’s digital transformation journey by implementing Opcenter Advanced Planning and Scheduling and Mendix in their production processes. This collaboration marks a significant step towards optimising their manufacturing operations, enhancing agility, and addressing the complexities of modern production,” said Alex Teo, managing director and vice president, South East Asia for Siemens Digital Industries Software. “By leveraging our advanced technologies, Freyabadi is prepared to overcome its production challenges, enabling more efficient and reliable delivery of high-quality chocolate products to the global market. Together we’re not just improving processes but setting a new standard in the confectionery industry.”

| Tel: | +27 11 652 2000 |

| Email: | [email protected] |

| www: | www.siemens.co.za |

| Articles: | More information and articles about Siemens South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved