Water tension – a critical parameter

Everyone has walked along a wet beach at some time and noticed how the damp sand wobbles like jelly when stepped on several times. This may be fun on a beach, but it’s no joke at a construction site or in an earthquake. Houses and streets built on drained swampland or unconsolidated soil or sediment can sink in certain situations, after which they must be condemned for use. This phenomenon is known as soil liquefaction, and it can be dealt with by compressing the earth at construction sites where new structures are to be built.

Structural damage caused by soil liquefaction

Soil liquefaction occurs when water in the earth, in most cases groundwater, cannot drain quickly enough. This leads to a significant increase in hydrostatic pressure in the ground, which in turn causes the earth to move, and in many cases, the structures upon it. Even minor vibrations can trigger this effect.

The earthquake that struck Christchurch, New Zealand, in 2011 showed how sandy soil full of water can turn to mush. With a magnitude of 6,2, the earthquake was relatively moderate, but its epicentre was within the city limits and relatively close to the surface. The soil liquefaction that occurred as a result made most of the city uninhabitable. This is because the centre of Christchurch sits atop sandy ground saturated with water that formed from an alluvial fan, a cone-shaped deposit of sediment created by three rivers.

Sloping ground and ground next to rivers and lakes can also slide on a liquefied soil layer and cause large cracks or fissures to open. This damages not only buildings, bridges and roads but also networks for water, natural gas, wastewater, electricity and telecommunication services – and underwater tanks and manholes can also start floating in the earth.

Cone penetration testing

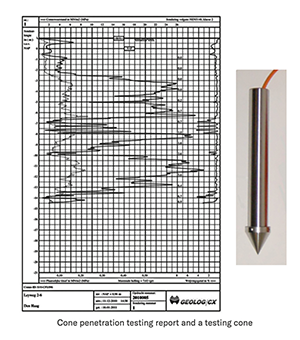

To prevent such scenarios, the ground at construction sites must be thoroughly analysed before any work is planned. The cone penetration testing method was developed in the Netherlands at the end of 1950, and has since been used as an economical soil investigation method. This method gives a good picture of the soil structure and the various soil layers. It is used globally in all areas where significant changes in soil-bearing capacity may occur if drilling and building activities etc., are to be carried out.

Cone penetration testing involves pressing a cone-shaped tip into the ground at a constant speed. A specially-equipped truck is used for the test. The testing results are illustrated in a graph that shows the cone resistance in relation to the cone depth. Along with soil resistance, the cone sensors used in the test measure the inclination of the cone, the friction ratio, soil temperature, conductivity, and water tension. The latter parameter is measured using the 21Y pressure transmitter from KELLER.

Series 21Y piezoresistive pressure transmitter

Y-line transmitters have a very low temperature error which is achieved by utilising an additional circuit with a temperature sensor that subdivides the temperature range into fields of 1,5 °K each. Compensation values are calculated for each temperature field, which are fed into the analogue signal path during operations, depending on the current temperature in each case. Viewing this way, one could say that these transmitters always operate at calibration temperature. A high degree of vertical integration, a modular design, and programmable electronics enable high volume, customer-specific production.

The 21Y series also stands out through its exceptional resistance against electromagnetic fields. The units display values that fall below the limits of the CE standard by as much as a factor of ten in the case of conducted and radiated fields. The transmitters are also highly immune to external voltages between the housing and the electrical connection, which is particularly important when used with frequency converters. A high-insulation voltage of 300 V also makes this product ideal for use in the roughest environments.

| Tel: | +27 10 595 1831 |

| Email: | [email protected] |

| www: | www.instrotech.co.za |

| Articles: | More information and articles about Instrotech |

© Technews Publishing (Pty) Ltd | All Rights Reserved