Lake Kivu presents a fascinating case study in limnology and geochemistry. Its unique characteristics are primarily driven by its location within the East African Rift Valley, a tectonically active region characterised by volcanic activity and high heat flow.

The nearby Nyiragongo and Nyamuragira volcanoes release large amounts of carbon dioxide (CO2), a key precursor to methane (CH4) formation.

Organic matter from the lake’s ecosystem, including plankton and other organisms, sinks to the bottom, where it undergoes anaerobic decomposition by microbial communities. Without oxygen, microbes convert the organic matter into methane as a byproduct of their metabolism. Due to its low solubility in water, methane accumulates in the lake’s deeper, colder layers, forming a gas-rich hypolimnion. The dissolved carbon dioxide from the volcanic sources also contributes to the gas accumulation, creating a potentially explosive mixture.

The high concentration of dissolved gases in Lake Kivu poses a significant risk of a limnic eruption, a rare but deadly event where the gases erupt to the surface, suffocating life in the surrounding area. However, the benefits in this case outweigh the risks − the methane reserves represent a substantial energy resource. The process of gas extraction and utilisation must be carefully managed to minimise environmental impacts on the lake ecosystem.

Resource exploration and extraction

Methane exploration in Lake Kivu has primarily focused on gas composition analysis, determining the exact composition of the gas mixture, including methane, carbon dioxide and other potential components, and gas quantity estimation by assessing the total volume of methane available within the lake’s depths.

Various challenges presented themselves during the gas extraction process at Lake Kivu. Given the depth at which the methane was concentrated, specialised equipment and techniques were required. Once extracted, the gas mixture was separated into its components, primarily methane and carbon dioxide. Environmental impact mitigation had to be considered, and careful planning was essential to minimise the impact of extraction on the lake’s ecosystem and surrounding communities.

KivuWatt was a notable example of a successful methane extraction and power generation project on Lake Kivu. It demonstrated the feasibility of harnessing this unique resource while also highlighting the complexities involved. The extracted and processed methane was available for use as fuel for power plants to generate electricity. Alternatively, the methane could be utilised for industrial processes or converted into other energy forms.

Understanding the challenge

Lake Kivu presented a unique set of challenges for instrumentation due to the extreme underwater environment. Instrumentation in this environment faced extreme challenges − high pressure, low light and corrosive conditions. Precise monitoring of gas levels and interfaces for safety and efficiency was of critical importance, and continuous operation in this demanding environment was crucial.

VEGA instrumentation solution

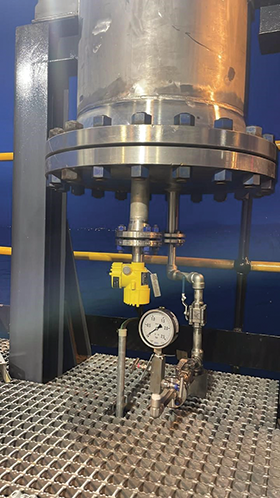

The VEGABAR 82 pressure transmitter was used for differential pressure measurement, the key to monitoring gas levels within the lake. It offered high precision and ensured accurate data for decision making. Its rugged design was capable of withstanding the harsh underwater environment. The VEGAFLEX 81 level sensor was equipped with guided wave radar technology, which was ideal for level measurement in liquids and gases. Its accurate interface detection was crucial for determining the gas-liquid boundary. VEGA instrumentation is known for reliable operation, which in this application ensured consistent performance in challenging conditions.

Bypass chambers housed the instruments and provided a controlled environment for their operation. The 180 metre cable of the VEGAFLEX 81 allowed for data transmission from the underwater instruments to the surface control system. Real-time data received from the sensors were used to monitor gas levels, calculate extraction rates and implement safety protocols.

The VEGA sensors offered an early warning system where accurate gas level monitoring enabled early detection of potential gas eruptions. It allowed for optimised extraction rates as precise measurements allowed for efficient gas extraction without compromising safety. The VEGA instruments deployed in this application were key in the environmental aspect of the extraction process, as monitoring gas levels helped prevent gas leakage and protect the lake ecosystem. The successful deployment of these sensors in this challenging environment represented a significant technological advancement in data transmission and seamless integration into the extraction processes, as reliable data transfer over long distances underwater was essential for the project’s success.

The integration of instrumentation with the overall extraction system optimised operations, reducing cost and increasing safety.

The use of VEGA instrumentation in the Lake Kivu methane extraction project demonstrated the critical role of advanced technology in addressing complex engineering challenges. By providing accurate and reliable measurement data, VEGA contributed to the safe and efficient development of this vital energy resource.

For more information contact VEGA Controls SA,

| Tel: | +27 11 795 3249 |

| Email: | [email protected] |

| www: | www.vega.com/en/home_za |

| Articles: | More information and articles about VEGA Controls SA |

© Technews Publishing (Pty) Ltd | All Rights Reserved