The UK aims to build enough wind farms to power every household by 2030. Pulse Structural Monitoring was tasked with monitoring selected turbine foundations in new wind farms. The solution is delivered by using Beckhoff technology, and EtherCAT measurement terminals in particular, throughout the design. Offshore wind farms present difficulties due to the environment, making continuous monitoring of the whole turbine essential. By continuously monitoring the turbine, blades and foundation performance, decision making on planned maintenance and design validations can be supported, which helps to avoid unplanned shutdown periods, or making costly repairs in the event of failure.

Environmental and operational loadings on the turbine affect all parts of the dynamically loaded structure. Part of the foundation’s role is to support the wind turbine generator (WTG) load, provide stability and absorb additional loadings. The structural health of the foundation, which is considered as the top of the tower downwards, is critical to the performance and support of the WTG’s performance. Structural health monitoring (SHM) systems for offshore wind turbine structures monitor a combination of corrosion and dynamic fatigue stress.

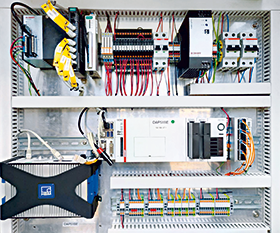

Pulse Structural Monitoring is delivering foundation SHM systems for clients in the renewables industry across the world using Beckhoff technology. Utilising Beckhoff’s broad range of I/O terminals for sensor integration allows Pulse to ensure time-stamped data acquisition throughout the structure. Pulse uses the ELM370x module, which is an analog input terminal from the EtherCAT measurement range. Due to the high sensitivity and measurement ability of these ELM modules, they are often used within laboratories but can also be integrated into industrial environments. This terminal can be set to over 30 different types of electrical signal, which makes it an exceptionally flexible measurement module for a range of sensors.

To determine the structural integrity throughout the full height of the structure accurately, helping to ensure turbine operational efficiencies, the tower itself requires measurement points on four levels. This means that the I/O needs to be distributed to have accelerometers and full bridge strain gauges terminated close to where they are positioned. Each level on this top section demands two ELM3704 modules for the varied signals, an EK1100 EtherCAT Coupler for communication, and a PS1011 power supply. These are fully enclosed and magnetically attached to the tower wall at defined heights, giving accurate data capture across the tower.

For temperature, Pulse uses the standard EL3202 terminal, a Beckhoff analog input RTD EtherCAT terminal that provides data to allow for compensation algorithms to operate. This synchronisation is key to the critical analysis of the overall structure, taking data from high-precision accelerometers, strain gauges and temperature sensors located along the length of the structure, from the top of the tower to the foot of the monopile with the exact timing.

Pulse has adopted the EtherCAT fieldbus, and deploys this technology with the added benefit of power and communication through a single cable. EtherCAT P and EtherCAT/Ethernet with power (ENP) help circumvent the common difficulty of getting power to the sensors and distributed I/O at the top of the tower. The EtherCAT P and ENP system can run power and communications through a single cable and daisy-chain the fieldbus throughout the structure. “The most important thing in our industry is data,” says Stephen Harford, solutions architect at Pulse. “EtherCAT is already fast, which is essential for synchronisation and getting the data we need. But EtherCAT, with distributed clocks at every level, allows us to keep full synchronisation. With Beckhoff, the quality of the technology is always guaranteed.”

From Harford’s point of view, partnership is also important: “Beckhoff has also made every effort to help us keep to the tight schedule that wind farms have. They have supported us at every stage, coming down to train us when we could not make it due to our tight schedule. This is why we are happy to partner with Beckhoff on other projects we have.”

All the data from the sensors is centralised and collected in a Beckhoff embedded controller. The CX2062 was chosen for its flexibility in expanding memory, increasing interfaces and processing power to run the TwinCAT runtime software plus the data management and processing application developed by Pulse. Beckhoff provides a free and open DLL to access all real-time data within the TwinCAT system via ADS. This open platform allows Pulse to both analyse data and send it directly to the higher level scada system, providing key insight to the turbine’s health.

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved