Industrial processes present risks and have the potential to cause incidents with serious consequences for both people and the environment. In the last few years, the process industry has seen a growing demand for measuring devices in safety critical or hazardous areas.

To help customers meet these safety requirements, Endress+Hauser has recently launched a new generation of the well-known and trusted Deltabar and Cerabar family.

These pressure devices increase process safety and productivity through their smart safety approach.

Improve process safety with a smart approach

‘SIL from the factory’ is the development of a product according to IEC61508. By complying with this international standard, measuring devices can be used in SIL applications as soon as they are launched in the market. With the implementation of IEC 61508, manufacturers of measuring devices ensure the elimination of intensive operational tests and at the same time reduce any form of systematic error to a minimum.

But one sensor alone is never responsible for all errors in a process. Many errors are also caused by incorrect or faulty commissioning or changes after commissioning. To counteract these errors, Endress+Hauser’s new pressure measurement devices are equipped with guided operating sequences which guide the user step by step through the commissioning, the SIL locking of the sensor, and provision of the necessary assistance for the SIL proof tests.

If the user correctly follows the guide through the commissioning sequence, the device will form an automatically generated checksum (CRC). This checksum contains all safety-relevant parameters. Thus, it can be seen whether a parameter was modified after the initial commissioning. An additional feature that speeds up the monitoring during operation is the backlight of the display. In the event of an error, it changes from green to red. The colour change allows the operator to immediately notice malfunctions without having to open the menu structure of a device.

Increased productivity through digitally optimised processes

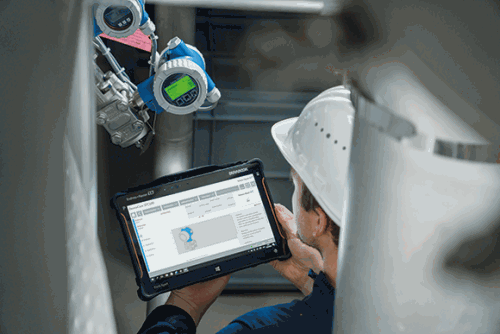

Nowadays, users are challenged with having to operate multiple measuring instruments supplied by a variety of manufacturers. Intuitive operation is therefore an enormous relief in the user’s daily life. With the new Cerabar and Deltabar pressure devices from Endress+Hauser, the user can benefit from intuitive parameterisation. The Bluetooth interface also allows users an easy and safe way to operate devices that were previously difficult to access or in danger zones.

Despite all the progress made to date, data security should not be underestimated. Endress+Hauser’s Bluetooth communication is based on a special protocol that meets the high security requirements for industrial use. The Bluetooth protocol was tested by the Fraunhofer Institute AISEC. At the end of testing, the protocol and the algorithm were rated with the protection level ‘High’, which means that manipulation attempts during the connection between app and device can be almost completely excluded.

In addition to the operation of the device, the availability of device information is also extremely important. With an electronic nameplate (RFID or QR code) the user has the possibility to display all device-specific information in real time. This includes not only the device documentation, but also product availability and suitability of spare parts for the device.

Unlock your IIoT potential

The Cerabar and Deltabar pressure devices are an investment for the future. Equipped with Heartbeat Technology, they combine proven measurement technologies with IIoT applications. This enables predictive maintenance.

One of the ways to simplify the operator’s daily work is to provide data-based insights into their process. In return, these insights can be used to optimise production processes.

At Endress+Hauser, transparency is made possible by Heartbeat Technology, which has already been successfully deployed into other measuring instruments in recent years.

The concept is based on 3 pillars: diagnosis, verification and monitoring.

The continuous self-diagnosis function of the pressure transmitter covers more than 95 percent of measuring device functions. If the device detects an irregularity, it informs the operator via the standardised NAMUR status message and indicates measures to restore the device.

The verification functionality allows users to perform a verification procedure without interruption of the process, and obtains the documented verification results. The automatically generated verification protocol provides the evidence required to support regulations, which enables the maintenance requirements for the next system checks to be determined in advance, saving a considerable amount of time during planned shutdowns.

The Heartbeat monitoring function detects irregularities in the process. By recording measured variables, such as pressure peaks caused by water and steam hammer, the operator is provided with the necessary data to carry out predictive maintenance for the surrounding plant components. In addition, deviations in loop resistance and blocked impulse lines can be detected at an early stage. All this improves the understanding of the maintenance process considerably and enables precise maintenance planning.

Advantages at a glance

Reliable and secure thanks to:

• Development according to IEC 61508.

• Automatic checksums after SIL locking procedure.

• Guided sequences for SIL locking and proof tests.

Simple operation for the user thanks to:

• Intuitive commissioning via Bluetooth interface.

• Operation by optical keys without opening the housing cover.

• HistoROM ensures easy transfer of parameters.

Fit for the future thanks to Heartbeat Technology:

• Verification in installed condition without process interruption.

• 24/7 self-diagnosis of the device.

• Monitoring of parameters for the improvement of process quality.

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved