In an era where precision, performance and smart control define industrial success, the right driver can make all the difference. At Axiom Hydraulics, we’ve seen how the Sun Hydraulics XMD series transforms hydraulic systems, from mining and construction to agriculture and automation.

When implementing variable control in a hydraulic system the greatest concern for clients is often the complexity of programming and installing advanced control systems.

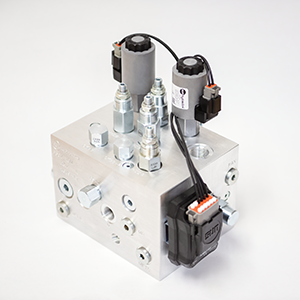

Sun Hydraulics offers a fresh simple solution. The electro-proportional XMD drivers are designed to control hydraulic valves with precision and ease with minimal configuration required, all managed via an app on your phone. These drivers have a proven track record across a range of industries.

For example, a shipping vessel operating off the South African coast needed more control over its winch trawling system. The original setup was fixed-speed, sufficient in calm conditions, but undesirable in unpredictable seas. The goal? A flexible and safer system. Axiom Hydraulics proposed a retrofit: pairing a Sun XMD-01 driver with a pressure-compensated FREP XCN flow control valve. Thanks to the XMD’s IP69K rating the unit could be mounted anywhere on the vessel, even in exposed environments. A simple 5-volt reference signal from the XMD allowed the captain to control winch speed directly from the bridge via a dial, bringing confidence and control to every operation.

In another project, a client sought variable speed control for a conveyor system that started and stopped every minute. The XMD was configured to ramp the conveyor’s speed up and down over a two-second period ensuring smooth transitions and reducing mechanical shock.

The XMD has also proven invaluable in testing environments. For instance, closed-loop hydraulic pumps require testing after repair. Operators used a human-machine interface (HMI) to select target speeds which were communicated to an XMD-01 via CANbus. The driver brought the pump into stroke delivering the required flow with high repeatability.

More advanced control was achieved using the XMD-02 in a press application requiring constant load. Configured for PID closed-loop control the driver received input from a load cell and continuously adjusted a proportional relief valve to maintain the desired force throughout the cylinder stroke.

Temperature control has also been addressed using the XMD. In one project, an unloading relief valve and temperature probe were used in conjunction with an HMI display. The XMD was programmed to fully energise the system when the temperature dropped below the setpoint, keeping the hydraulic fluid within an optimal range.

In all of these projects, the XMD drivers have consistently proven themselves in tough conditions earning their place as our go-to solution for variable control in hydraulic systems. At Axiom Hydraulics, we’ve seen what’s possible when smart components meet real-world challenges. Across industries, environments and applications, Sun’s XMD electro-hydraulic drivers have consistently delivered one thing: control without complexity. Whether you’re retrofitting a winch at sea, fine-tuning a conveyor line or running precision press operations, these drivers bring confidence, adaptability and performance to your hydraulic systems.

For engineers and integrators looking for intelligent, flexible control without the learning curve, the XMD drivers are more than a product − they’re a powerful tool for the next generation of hydraulic systems.

For more information contact Axiom Hydraulics,

| Tel: | +27 11 334 3068 |

| Email: | [email protected] |

| www: | www.axiomsa.co.za |

| Articles: | More information and articles about Axiom Hydraulics |

© Technews Publishing (Pty) Ltd | All Rights Reserved