Danfoss debuts Alsense

November 2020

IT in Manufacturing

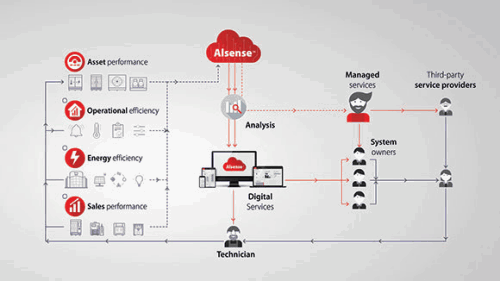

Danfoss has updated and enhanced its service offering to create a more sustainable, scalable and secure cloud-based portal for managing food retail operations. Previously known as Danfoss Enterprise Services (DES), Alsense is optimised to provide new levels of efficiency. Food retailers can reduce their net energy consumption by up to 30% with Alsense, saving money and reducing food waste.

“We’re excited to offer a modern interface and powerful cloud capabilities to our food retail service customers,” said Thomas Kolster, head of service innovation at Danfoss Cooling. “The added benefits can make it significantly easier to track asset performance, respond to alarms and reduce energy consumption, thus lowering overall operational costs and extending asset lifetime. This is an ideal cloud solution for those looking to keep day-to-day operations efficient and cost-effective.”

Increased efficiency and streamlined performance

All services are integrated into one hub, offering a seamless user experience and added functionalities. Some of these include:

• Actionable insights – rather than cluttered dashboards, Alsense delivers relevant, easy-to-digest insights. This allows customers to take corrective actions faster, significantly reducing food and energy waste.

• Increased security and availability – Alsense allows for easy expansion to different regions, with higher serviceability and a new VPN structure for added security.

• Improved performance and stability – the new service platform on Microsoft Azure provides smoother service operation, faster reaction to alarms, reduced nuisance alarms and higher asset uptime.

• Dynamic feature roadmap – features will be updated and introduced every two weeks. This provides customers with continued enhancements based on real-time feedback.

• Responsive portal – whether on a mobile device, tablet or desktop, users will experience a seamless, responsive portal. This increases ease of use and accessibility to necessary information at a desk or on the go.

Trusted partnership

With the updated Alsense platform, customers can depend on the combined expertise of two notable enterprises. Danfoss brings more than 80 years of engineering and mechanical experience to its cloud-based services enabled by the new platform powered by Microsoft Azure. Microsoft has the trusted security, scalability and sustainability that customers have come to expect in their digital tools.

Further reading:

How digital infrastructure design choices will decide who wins in AI

Schneider Electric South Africa

IT in Manufacturing

As AI drives continues to disrupt industries across the world, the race is no longer just about smarter models or better data. It’s about building infrastructure powerful enough to support innovation at scale.

Read more...

How quantum computing and AI are driving the next wave of cyber defence innovation

IT in Manufacturing

We are standing at the edge of a new cybersecurity frontier, shaped by quantum computing, AI and the ever-expanding IIoT. To stay ahead of increasingly sophisticated threats, organisations must embrace a new paradigm that is proactive, integrated and rooted in zero-trust architectures.

Read more...

2026: The Year of AI execution for South African businesses

IT in Manufacturing

As we start 2026, artificial intelligence in South Africa is entering a new era defined not by experimentation, but by execution. Across the region, the conversation is shifting from “how do we build AI?” to “how do we power, govern and scale it responsibly?”

Read more...

Five key insights we gained about AI in 2025

IT in Manufacturing

As 2025 draws to a close, African businesses can look back on one of the most pivotal years in AI adoption to date as organisations tested, deployed and learned from AI at pace. Some thrived and others stumbled. But the lessons that emerged are clear.

Read more...

South Africa’s AI development ranks 63rd in the world

IT in Manufacturing

The seventh edition of the Digital Quality of Life Index by cybersecurity company, Surfshark ranks South Africa 75th globally.

Read more...

Optimising MRO operations through artificial intelligence

RS South Africa

IT in Manufacturing

AI is reshaping industrial operations at every level in the maintenance, repair and operations supply chain, where it is driving efficiency, predictive insight and smarter decision making.

Read more...

Data centres in an AI-driven future

Schneider Electric South Africa

IT in Manufacturing

A profound transformation will begin to take hold in 2026 as AI becomes ever more ingrained in every aspect of life, and the focus shifts from LLMs to AI inferencing.

Read more...

Driving innovation in agricultural machinery

Siemens South Africa

IT in Manufacturing

A leading Argentine agricultural machinery manufacturer, Crucianelli has adopted the Siemens Xcelerator portfolio of industry software to drive innovation and digital transformation of its business, from product ideation and development to production and to its extended dealer network.

Read more...

Don’t let the digital twin drift from reality

Schneider Electric South Africa

IT in Manufacturing

The digital twins is a highly effective tool that offers real-world scenarios within a virtual environment. However, there is the danger of a disconnect stemming from a communication failure between the design, construction and operations phases of a project.

Read more...

Install and commissioning time cut by 50% thanks to digital twin insights

IT in Manufacturing

ECM Technologies, a world leader in the design and manufacture of innovative and modular low-pressure carburising industrial furnaces, has developed a solution that removes many of the installation and commissioning challenges relating to the development, testing and deployment of large-scale heat treatment plants.

Read more...