The theme for the Mining Indaba 2020 – ‘Optimising Growth and Investment in the Digitised Mining Economy’ – reinforced the need to focus on innovation, technology and automation. Technology, implemented alongside the correct logistics and strategy, makes a significant difference to age-old industries. The mining industry has never before faced such challenges as it does now. It is in urgent need of transformation.

SICK Automation has the technology capable of making that change.

SICK’s ‘Sensor Intelligence’ draws on its complete system expertise, supplemented by over 70 years’ experience as a market leader in sensors and sensor application solutions. SICK combines detailed application knowledge with reliable software architecture to optimally integrate its sensors into your system.

South Africa is leveraging technologies to improve mining efficiency and safety, and is fine-tuning the transformation from manual operations to more automated mining. SICK Automation is leading the way as a continual mining brand. Whether it is an underground or open-cast mine, the company has an automation solution that has been industry tested and optimised to suit South African mining conditions and needs.

A global specialist for factory automation, logistics and process automation applications, SICK Automation has over 44 000 products for the most challenging industry applications that require high precision proximity detection systems. Apart from its level, pressure, flow. presence detection, machine vision and other products, the company is an industry leader in the following fields:

Laser and radar scanners

SICK is globally renowned as a leader in laser scanner innovation and has been researching and developing this technology for over 40 years. Today, its laser scanners are used around the world for geo-mapping, exploring the universe at terrestrial space observatories, to protecting miners deep under the Earth’s surface.

Designed for indoor and outdoor applications, for day and night use, and with special weather filters, these laser scanners can go where humans cannot, and reach levels that no other product can. SICK’s extensive range of laser scanners provides intelligent scanning solutions for wide-reaching logistic and automation requirements. Applications for mining include:

Material flow and volume measurement

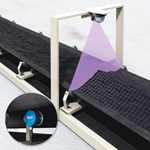

If users need to measure bulk materials on conveyor belts or in piles, the laser volume flowmeter Bulkscan offers a precise measuring procedure and an appealing alternative to a belt scale. The Bulkscan continuously measures the flow rate without making contact – regardless of weather conditions and the condition of the material. Intelligent additional functions on Bulkscan LMS511, such as measurement of the centre of gravity, height of the bulk, and belt monitoring prevent damage to the machines and conveyor belts – a definite benefit when optimising the flow of goods and efficiently controlling conveyor belts. The Bulkscan is exemplary in both maintenance and cost-effectiveness, and, thanks to a special alloy housing and integrated heating, it is robust and suitable for outdoor use.

Driver assistance and collision avoidance

Large vehicles within the mining industry pose a continuous challenge to life and infrastructure. Turning, cornering and reversing in close proximity to walls and drop offs or other equipment and people can result in damage or fatality. High precision proximity detection systems monitor available distance and identify potential collision hazards.

Suited for most underground mining vehicles, and using advanced laser scanner technology, underground vehicle operators are assisted to safely and efficiently manoeuvre within the tunnel. From front and rear-end detection, to corner cutting and overshooting, drivers receive visual feedback on a touch screen display as well as audible alarm warnings.

On surface mines, in dusty and harsh environments, the risk of collision is a reality. SICK has developed radar sensors that are able to withstand dirt and hostile weather conditions, as well as temperature fluctuations ranging between -30 and 50°C. These sensors provide reliable detection of any object which falls within their detection cones up to 20 metres.

Driver assistance systems, using 3D LiDAR or vision sensors detect blind zones around vehicles and warn the operator of potential sources of danger as well as providing navigation and steering support. The sensor detects up to 55 000 measurement points across four layers and emits three echo signals per measuring beam, increasing the number of measurement points to up to 165 000 per second.

Continuous emissions monitoring systems (CEMS)

The Carbon Tax came into effect on 1 June 2019 in South Africa, and will be phased in over a period of time to allow companies to comply and adopt cleaner and more efficient technologies. SICK has tried and tested technologies in use across the globe. Its CEMS solutions have been specifically designed for measuring emissions at mining and industrial facilities. These systems measure pollutants, reference quantities, and perform data processing on the results in accordance with relevant national or international legislation.

Conclusion

Technology has an important role in the mining industry. Countries that implement national initiatives that drive transformation and inclusive, broad-based development goals are far more enticing to investors. Research and development in the mining industry as well as the adoption of innovation are the keys to the sustainability of the industry in South Africa and the rest of the continent.

Whatever the distance, whatever the dimensions, for indoor, outdoor and underground applications, SICK offers consulting and design services so that its solutions are uniquely tailored to a mine’s specific requirements be it for the copper, coal, diamond or platinum sectors.

| Tel: | +27 10 060 0550 |

| Email: | [email protected] |

| www: | www.sick.com/za/en/ |

| Articles: | More information and articles about SICK Automation Southern Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved