Onsite energy utilities such as boilers must be independently managed to achieve meaningful performance outcomes. Associated Energy Services (AES) frequently finds that companies incorrectly rely on a single fuel-to-product usage ratio to capture energy metrics and performance. “This has significant implications as cost pressures, competitive forces and other challenges have decimated South Africa’s manufacturing sector in recent years. These aspects should be independently managed to give the site the best possible chance of maintaining competitiveness while maximising profit margins,” advises AES commercial director, Dennis Williams.

One size does not fit all

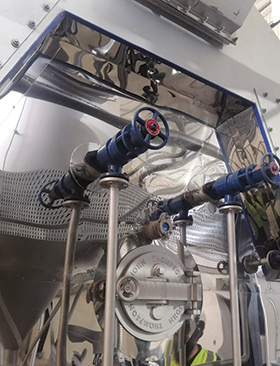

Williams emphasises that thermal energy operations and utilisation in production facilities comprise two major processes, the conversion/generation process and the production/utilisation process. Multiple measurements are essential, including water meters to assess feed water to boilers and makeup water; temperature probes to measure condensate and feed water temperature; and specialised probes to measure the CO2/ O2 in flue gas. It is also important to monitor steam splits and condensate return volumes.

“At the outset, AES conducts an energy analysis, identifying the current baseline and comparing it to client outcome expectations or AES’s best-case performance baseline. A more detailed energy analysis follows once AES is on site managing the client’s boiler operations and proactively addressing cost, efficiency, emissions performance, reliability and uptime,” Williams explains. AES’s experience, expertise, systems and methodologies are constantly applied via a system of meticulous and ongoing checks. “This intense level of energy management is often beyond the scope of clients,” he continues.

Implications of not doing energy management

Failure to undertake regular energy management assessments has massive safety implications. This involves combustion, heat, dust, gases, rotating equipment and electricity. Process safety management manages activities where there is an element of risk, and specific personnel are trained in hazard identification and risk assessment. The team members are tasked with identifying and quantifying risks, which are then rolled out into management tools and work procedures, ensuring that all on site have specific work instructions, information and training on how to execute the relevant activities safely.

Failure to conduct operational performance evaluations also results in higher operating costs (fuel and maintenance), increased plant downtime, a higher carbon footprint and reduced lifespan of the plant.

Benefits of proactive energy management

Williams says that the more efficient the combustion and the lower the losses as unburnt carbon in ash, or CO2 in flue gas, the more efficient the management of the heat transfer process becomes and the lower the energy losses. Use of fuel − by far the highest cost − can be managed effectively through the recovery of the energy released (boiler heat transfer), ensuring that the maximum amount of energy is recovered from the fuel to steam process. Closely aligned with this are fuel costs and quality. Through its in-house laboratory, significant buying power, access to market supply and sourcing expertise, AES ensures that the best quality fuel is procured at the lowest cost.

The quality of the steam supply is another key consideration. This relates to stability of steam pressure, maximisation of condensate return, the dryness of steam and the reliability/continuity of steam supply. These all impact on how a company can effectively use the steam supplied to maximise efficiency and lower usage per unit of product.

Efficient operations also positively impact key aspects such as sustainability and emissions. Improved boiler efficiency and maximisation of condensate return in turn lower resource usage (coal and water) per unit of production. Effective maintenance management including scheduling, quality execution, planning and recommissioning all impact on efficiency and plant reliability.

Proactive energy management pays off

The beneficial outcome of effective energy management is best illustrated by a pilot project that AES undertook for a multinational FMCG client. This entailed the installation of an additional boiler, mitigation of liquid fuel use and overall outsourcing of operations. Following operational takeover and maintenance/operations interventions by AES, there were significant improvements. There was a 100% reduction in costly liquid fuel use for steam generation and a 21% improvement in CO2 emissions when compared with the client’s operational baseline.

As a result, the client outsourced its largest steam generation facility to AES, achieving similar results with lower steam cost, improved availability and a staggering 35% reduction in fuel use and associated CO2 emissions. This was proof indeed that proactive energy management pays off. AES now services five of this client’s sites.

For more information contact AES,

© Technews Publishing (Pty) Ltd | All Rights Reserved