Quantum computers require extreme cooling to perform reliable calculations. One of the challenges preventing quantum computers from entering society is the difficulty of freezing the qubits to temperatures close to absolute zero. Now, researchers at Chalmers University of Technology, Sweden, and the University of Maryland, USA, have engineered a new type of refrigerator that can autonomously cool superconducting qubits to record low temperatures, paving the way for more reliable quantum computation.

Quantum computers have the potential to revolutionise fundamental technologies in various sectors of society, with applications in medicine, energy, encryption, AI, and logistics. While the building blocks of a classical computer – bits – can take a value of either 0 or 1, the most common building blocks in quantum computers – qubits – can have a value of 0 and 1 simultaneously. The phenomenon is called superposition and is one of the reasons why a quantum computer can perform parallel computations, resulting in enormous computational potential. However, the time a quantum computer can work on a calculation is still significantly constrained because it spends a lot of time correcting errors.

“Qubits, the building blocks of a quantum computer, are hypersensitive to their environment. Even extremely weak electromagnetic interference leaking into the computer could flip the value of the qubit randomly, causing errors and subsequently hindering quantum computation,” says Aamir Ali, research specialist in quantum technology at Chalmers University of Technology.

Demonstrates record low temperatures

Today, many quantum computers are based on superconducting electrical circuits that have zero resistance and therefore preserve information very well. For qubits to work without errors and for longer periods in such a system, they need to be cooled to a temperature close to absolute zero, equivalent to minus 273.15 degrees Celsius or zero Kelvin. The extreme cold puts the qubits into their lowest energy state, known as the ground state, equivalent to value 0, a prerequisite for initiating a calculation.

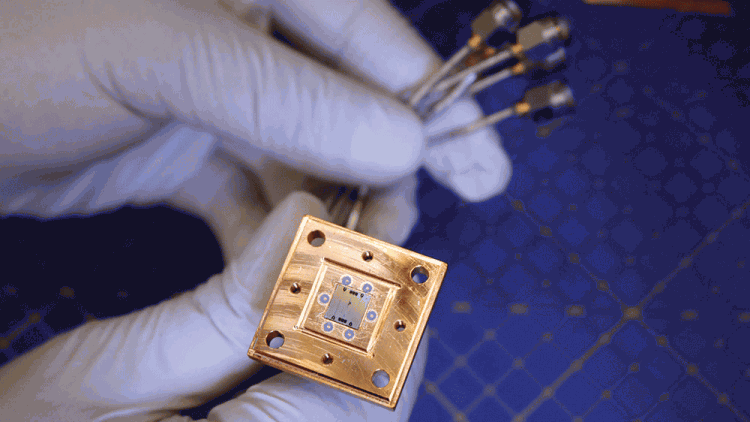

The cooling systems used today, namely dilution refrigerators, bring the qubits to about 50 millikelvin above absolute zero. The closer a system approaches to absolute zero, the more difficult further cooling is. According to the laws of thermodynamics, no finite process can cool any system to absolute zero. Now, the researchers have constructed a new type of quantum refrigerator that can complement the dilution refrigerator and autonomously cool superconducting qubits to record-low temperatures. The quantum refrigerator is described in an article in Nature Physics journal.

“The quantum refrigerator is based on superconducting circuits and is powered by heat from the environment. It can cool the target qubit to 22 millikelvin, without external control. This paves the way for more reliable and error-free quantum computations that require less hardware overload,” says Aamir Ali, lead author of the study. “With this method, we were able to increase the qubit’s probability to be in the ground state before computation to 99,97%, which is significantly better than what previous techniques could achieve, that is between 99,80% and 99,92%. This might seem like a small difference, but when performing multiple computations, it compounds into a major performance boost in the efficiency of quantum computers.”

Powered naturally by the environment

The refrigerator utilises interactions between different qubits, specifically between the target qubit to be cooled and the two quantum bits used for cooling. Next to one of the qubits, a warm environment is engineered to serve as a hot thermal bath. The hot thermal bath gives energy to one of the quantum refrigerator’s superconducting qubits and powers the quantum refrigerator.

“Energy from the thermal environment, channelled through one of the quantum refrigerator’s two qubits, pumps heat from the target qubit into the quantum refrigerator’s second qubit, which is cold. That cold qubit is thermalised to a cold environment into which the target qubit’s heat is ultimately dumped,” says Nicole Yunger Halpern, NIST physicist and adjunct assistant professor of physics and IPST at the University of Maryland, USA. The system is autonomous in that once it is started, it operates without external control and is powered by the heat that naturally arises from the temperature difference between two thermal baths.

“Our work is the first demonstration of an autonomous quantum thermal machine executing a practically useful task. We originally intended this experiment as a proof of concept, so we were pleasantly surprised when we found out that the performance of the machine surpasses all existing reset protocols in cooling down the qubit to record-low temperatures,” says Simone Gasparinetti, associate professor at Chalmers University of Technology and lead author of the study.

© Technews Publishing (Pty) Ltd | All Rights Reserved