A technology leader driving the digital transformation of industries, with a history of innovation spanning over 130 years, ABB had a major presence at

ABB also focused on the latest trends and developments in these industries, from increased

An excellent solution for energy transformation in secondary distribution networks is ABB’s portfolio of

The CSS units are available in various configurations and materials, including steel, concrete and an innovative GRP housing. They are suitable for a range of industries, from renewables to utilities and infrastructure. “This is an innovation that reflects ABB’s commitment to creating safer, more efficient, and sustainable solutions for modern electrical distribution needs,” says senior vice president, Graham Abrahams.

Another groundbreaking innovation from ABB Electrification is the UniGear ZS1 switchgear, which supports applications from utility substations to industrial plants. It is available in various configurations, including single busbar, double busbar, and double level solutions. The switchgear features a slim panel width of only 500 mm, making it one of the most compact air-insulated switchgears available. Its unique design saves space, without compromising performance. Advanced safety features include a system that actively prevents electric shock accidents and enhances equipment safety. The UniGear ZS1 can handle up to 24 kV, 4000 A, and 63 kA, making it suitable for demanding environments. It also incorporates tubular busbar technology for optimised electricity distribution and improved heat dissipation.

The switchgear is IoT-enabled and integrates digital technologies for real-time monitoring and analysis. This allows for improved asset health management, predictive maintenance, and improved operational reliability. With over 500 000 panels installed worldwide, the UniGear ZS1 is a proven solution supported by ABB’s global network.

“It’s all about leveraging electrical infrastructure and technologies to improve efficiencies,” says sales manager, Martin van Zyl. This integration depends on several key pillars, including high-efficiency motors, advanced magnetic motor controls, hoisting technologies, and energy management systems, all part of a broad portfolio available from ABB.

ABB Ability eMine comprises a portfolio of electrification technologies enabling the all-electric mine, integrated with digital applications and services throughout to monitor and optimise energy usage. It ranges from the electrification of mining trucks to the entire mining process. In addition to haulage, the portfolio includes the electrification of ABB’s more traditional solutions for mining, like hoisting, grinding and materials handling.

An example of this is the pilot technology eMine FastCharge, set to be the world’s fastest and only fully automated charging system for mining trucks, offering up to 600 kW of power. Using trolley-assisted hauling, the eMine Trolley System can reduce diesel consumption and resulting carbon emissions by up to 90%, compared to exclusively diesel operations.

ABB had an energy efficiency demonstration at its stand, designed to showcase the energy savings achievable with drives compared to conventional damper-controlled fan systems or valve-controlled pump systems. The demo application highlights the power consumption of both scenarios as real-time bar graphs for easy comparison, and shows the calculated yearly savings. In addition, ABB provides energy efficiency appraisals to assist mining engineers determine the payback period of installing a

VSDs can be used in conjunction with energy-efficient, low-voltage motors based on

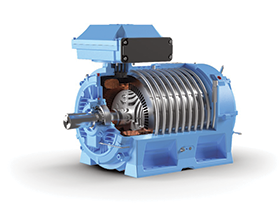

Next-generation SynRM motor technology combines ultra-premium energy efficiency with effective liquid cooling to deliver high-power density, quiet operation, and excellent reliability. Product marketing manager, Sean Mccree says that ABB is developing the world’s first IE5 SynRM liquid-cooled motors, ranging from

The new design sets a new benchmark for high power output and reliability in a compact footprint by combining the benefits of established ultra-premium energy efficiency with highly effective liquid cooling. A key advantage is the absence of fans or ventilation systems for cooling purposes, leaving the ambient air undisturbed. This feature is particularly beneficial in mining, where dust contamination can be problematic.

For safety in mining in particular, ABB has been engineering hoist systems for over 130 years to ensure efficient and harm-free mining. Global product manager, Mike Davis explains that ABBs latest products include the BHX hoist control system to enhance the safety, reliability and efficiency of hoist operations. It integrates seamlessly with other ABB technologies such as the ABB Ability NGX Hoist Control, which offers flexibility and can replace older or third-party systems.

The system is known for its ergonomic design and intuitive human-machine interface, making it user friendly for operators. In addition, ABB’s hoist control systems are equipped with advanced digital monitoring services like ABB Ability Performance Optimisation to track the status of the hoist and provide actionable insights continuously to improve uptime and productivity. “We are currently promoting a

ABB’s YuMi IRB 14000 is the first truly collaborative dual-armed robot, designed for a world in which humans and robots work together. It has been utilised in various industries to improve production efficiency and reduce waste.

ABB aligns its efforts with several UN Sustainable Development Goals, particularly SDG 7 (affordable and clean energy), SDG 8 (decent work and economic growth), SDG 9 (industry, innovation and infrastructure), and SDG 13 (climate action). ABB’s sustainability message is not just about gradual improvements but about transformative changes that drive real progress towards a sustainable future. The company is actively working with various stakeholders to embed sustainable practices across diverse industries and ensure that we all achieve a sustainable future.

| Tel: | +27 10 202 5000 |

| Email: | [email protected] |

| www: | www.abb.com/za |

| Articles: | More information and articles about ABB South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved