Behind every product request there is, or should be, a business objective. If we lose sight of the business objective, we often end up just papering over the cracks. This case study discusses an application of Turck Banner’s systems approach to working in unison with customers to achieve their business objectives, and it illustrates how the company’s Systems Division operates. To understand this systems approach, it is first necessary to have an understanding of the distinction between a product and a system.

A product is typically characterised by precise specifications and limited room for deviation. For instance, consider a temperature sensor which operates within a predetermined temperature range and may have features such as an analogue output, adjustable switch points, or a data output. Its primary function is to interface with other products, for example a PLC, to facilitate control, without any inherent ability to engage with humans. A system incorporates hardware components (products) with a software overlay, and these work in unison to fulfil a customer’s specific business objective. Such a system is then capable of product, machine-to-machine, machine-to-operator, and management interactions.

A product can be chosen and purchased from a catalogue, whereas a business objective creates a conversation, not a sale. The conversation creates a relationship, which results in a partnership to achieve the business objective.

A common phrase within Turck Banner’s Systems Division is “products talk to products, systems talk to people”.

A large, prestigious British car manufacturer set out to purchase a switch and a light. The initial enquiry was put through to Turck Banner’s Systems Division, where instead of asking what specifications were needed for the switch and light, a team member enquired about the objective.

The car plant had a U-shaped assembly line. The line began with an empty car shell, and finished with a full interior. Between the two ends were approximately 50 stations, each fitting parts of the interior, with the car remaining at each station for a set time (the Takt time). When the Takt time expired the car moved to the next station. If any station had not completed its task, the whole line stopped until that task was completed. Although there may have been many acceptable reasons why a task was not completed, not having the required part to fit to the car at the beginning of the Takt time was not one of them. In order to maintain a constant supply of parts to each station, a team of support staff with tow motors constantly moved around the path inside the U. When operators required more parts, they stepped away from their station to flag down one of them, and they then went to collect more parts and drop them at the station.

They called this the Milk Run. Station operators did not want to run out of parts, and as the time taken to replenish the stock was variable, operators often requested parts before they really needed them. This led to crates of parts backing up into the roadway, creating traffic jams, which increased the time taken to replenish the station.

The reason for the car manufacturer’s original enquiry for a switch and a light was to avoid having the operators flag down someone on the Milk Run, because while they were waving to attract attention they were not fitting the part, and the Takt time was counting down. The idea was for them to switch on a light above their station, which would be much quicker, and they could continue with their task.

While this may sound like a good solution, the Turck Banner systems team had other ideas. Together with the customer, the team looked at the whole part replenishment procedure, which consisted of three parts. The first part was a huge warehouse, which was a slow-moving area. Parts were replenished here from suppliers, with sufficient stock held to cover the production demand between supplier shipments. The second part was called the Supermarket, and held the stock required for one day of production, and this was replenished daily from the warehouse. The third part was the Milk Run, which delivered parts from the Supermarket to the stations.

The business objective was to maintain the supply of parts to every station in the most efficient way possible, ensuring that every station had the parts required at the start of each Takt cycle. The space at each station was limited, and some parts, like the seats, were very large, so a just-in-time solution was considered. The existing Milk Run was inefficient in the use of human resources and tow motors, and there was no empirical data on performance, only anecdotal. The systems team looked at both the whole replenishment procedure and the requirements of each individual station, from where they developed a solution.

As some of the parts, like door handles, were quite small, it was possible to have the stock required for a whole day’s production held at the station. These stations were restocked once a day before the shift started and could be excluded from the Milk Run. This reduced the traffic on the Milk Run by 28%, and freed up resources to be used more efficiently in the Call For Parts solution.

The Call For Parts solution

The Milk Run in its original format had several weaknesses. All the tow motors were constantly in motion, waiting to be flagged down. When they were flagged down, they were away from the Supermarket, so had to drive to the Supermarket before they could collect the required parts. The line operator had to leave the line to request parts. The objectives of the new system were:

1. The line operator should call for parts without leaving the station, and with minimal interruption.

2. Tow motors should only be in the Milk Run when they are delivering parts or returning with empty crates.

3. The floor space around each station should be used efficiently. Some parts were very large, like seats, and it was not practical to hold stock for more than a few Takt cycles. These stations required constant replenishment, while other stations using parts where a reasonable quantity could be held required replenishment less often.

4. Proper data generation and capture should be implemented.

The Call For Parts system

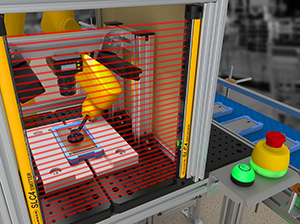

The operator at a station called for parts when one set of parts was needed by pressing a call button which was connected wirelessly to the Bus Stop. This was a new area adjacent to the Supermarket where the drivers waited with their tow motors. The order appeared on an HMI screen at the Bus Stop, showing the station and the parts required. The next driver in the queue accepted the order, which also informed the station that parts were being delivered. The driver collected the parts and delivered them to the station. At the station, the driver cleared the order by pressing a button, and took the empty crate to be restocked, then returning to the end of the driver queue at the Bus Stop. The times when the operator called for parts, when the order was acknowledged, and when the order was delivered, were all recorded for analysis.

The station delivery worked on its own Takt time, which was normally the same as the assembly line, but could be shorter. By reducing the delivery Takt time without changing the production Takt time, a stress test could be performed on the delivery system without harming production. The results of the reduction in delivery Takt time identified those stations that could be vulnerable to delivery failures. Remedial action could then be taken before a reduction in the production Takt time was implemented.

There were many benefits to the new system:

• Production delays due to waiting for parts were eliminated.

• Production increased.

• Fewer drivers were required for the deliveries.

• Floor space was saved and re-used for the Bus Stop.

• The whole replenishment procedure was more flexible. Stations could be easily included or excluded from the system.

• Quantifiable data was generated for analysis and future comparisons.

Having successfully delivered a solution, the focus of the systems team moved to adjacent operations. By paying attention throughout the definition and design stages to how the system could interact with upstream and downstream operations, improvements could be made both in isolation and in planned stages. This made proof of concept, procurement and funding easier.

Once Turck Banner established which products and system to deploy, the systems team worked alongside the customer to provide a solution, including ongoing support and expansion, allowing a look at the bigger picture and the complete system topology.

Finally, to deliver a complete solution, both the end user’s engineering team and the Turck Banner team worked with IT to create an interface between SAP and the line-side equipment. This was critical for the application to be a success, because without a reliable interface the best products in the world would be useless.

Turck Banner was founded as RET Automation Controls in 1984. In 2018 the company’s name was changed to Turck Banner when RET was purchased by Hans Turck (Germany) and Banner Engineering (USA), each owning a 50% share, to establish a South African joint venture company supplying both companies’ products to the southern African market. With over 50 years of cooperation, Turck and Banner have jointly continued to pave the way for future technology and solutions. This cooperation enables the offering of the widest range of products in the global market, offering a single source solution for both the OEM and the end user.

“This effectively means that, even though these are two separate and autonomous companies, it allows Turck Banner SA to be more competitive by offering complementary products to the southern African market. Additionally, it is this partnership and combined technology offering that allows the joint venture to be stronger together and represent more than just a joint venture,” says Brandon Topham, CEO of Turck Banner South Africa.

“Being an integral part of the Turck and Banner worldwide network of subsidiaries and representatives brings great advantages to our customers on many levels. Our customers, who themselves have international markets, are secure in the knowledge that their customers will receive the same high level of service. Our customers benefit from our connections, not just with the technical support services within our parent companies, but with the engineering, research and development, and logistics departments at those times when our customers urgently require less common parts.”

Turck Banner Southern Africa is known for quality and durable products, offering products that include award-winning sensors, wireless solutions, machine safety, indication, and LED lighting, while automation solutions increase the availability and efficiency of machines and plants in numerous industries, such as food and beverage, mining, pharmaceutical, chemical, and automotive, and in applications such as mobile machinery, intralogistics and packaging.

Since the start of the original company, and now Turck Banner Southern Africa, it has maintained its reputation for supplying high-quality sensing and automation equipment at competitive prices. By helping customers increase efficiency, reduce costs, and ensure quality, it has become the automation partner of choice in the southern African market.

| Tel: | +27 11 453 2468 |

| Email: | [email protected] |

| www: | www.turckbanner.co.za |

| Articles: | More information and articles about Turck Banner Southern Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved