Planar movers that travel like flying carpets are creating new possibilities in machine design. XPlanar, a new breed of transport system based on floating planar movers able to travel freely over a floor of planar tiles, brings unprecedented flexibility to product transport, and could revolutionise manufacturing plant and machine design. Beckhoff’s senior product manager of Drive Technology, Uwe Prüßmeier discusses the potential benefits that XPlanar offers users and machine builders looking to simplify machinery and boost performance.

The planar movers used to transport products can be positioned with absolute flexibility, anywhere within a two-dimensional space. How does this new freedom benefit product transport?

Prüßmeier: This ability to travel independently in two dimensions not only allows movers within a system to overtake one another on the same plane, called floor in XPlanar, but also to form product buffers and bypass these buffers. As a result, products no longer need to proceed from one processing station to the next in the exact same sequence. Instead, because the movers can be positioned literally anywhere, they can be sent to processing stations in any order; this means that each individual product need only travel to those stations required to process it. Clearly, this opens up huge potential when it comes to designing faster and more efficient process flows, and optimising machine and plant layouts, with a view to bringing down space requirements and costs.

Can you give specific examples of ways in which processes can be streamlined?

Prüßmeier: One example is that movers can easily be extracted from the production process – for example to allow maintenance or to discard flawed parts. Also, being able to set up special holding zones for in-process parts can lead to significantly better process efficiency. The ability to let faster movers overtake slower movers is useful too, as this allows sub-processes to execute swiftly, in parallel. Connecting up different sections within a plant is also easy. Another way to enhance process efficiency is to split up a machine’s product stream. Much like road traffic spread across multiple lanes at highway toll booths, separate product streams can be sent through different sets of stations to optimise processing, and then re-merged and synchronised later.

The movers can travel with six degrees of freedom. What particular benefits does this afford?

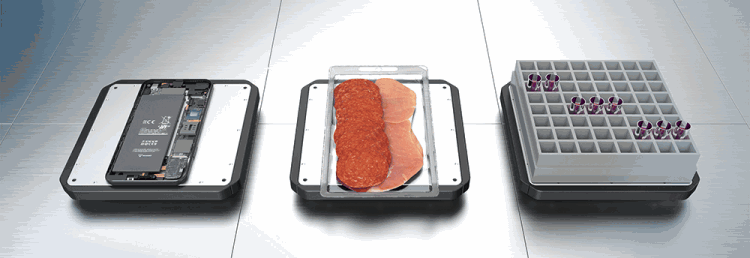

Prüßmeier: The planar movers not only carry payload products to their intended processing stations, they can also move the products inside the stations, rotate them through all three axes, and even ascend, descend and tilt a few millimetres to allow a product to be processed or inspected easily from any side. A slight tilt can also help prevent spills when accelerating quickly with a container full of liquid.

The planar floor over which the movers hover can be configured individually to suit specific machine designs. What role does this play in machine optimisation?

Prüßmeier: Here too, we put flexibility front and centre. The tiles can be laid out in any shape – and even wall or ceiling mounted – so the XPlanar system can be configured to suit a given application’s requirements perfectly. For instance, you can leave gaps within the tiled floor to accommodate processing stations or lay tracks around plant components. This means users can set up a transport system in a cost-optimised fashion, and at the same time reduce machine size to a minimum. In addition, it’s easy to modify the planar motor system subsequently, just by adding more tiles when necessary – for instance to accommodate new processing stations or gain extra space to optimise motion through curves.

Can XPlanar be used universally in machine and plant engineering?

Prüßmeier: Yes. There are almost no limits on using it in production plants and machines, provided a product’s weight and volume are within the planar movers’ payload carrying capacity. The system is particularly interesting for those sectors with special requirements in terms of hygiene and cleanability, zero emissions or low noise, because mover transport is contact-free, and therefore silent and completely wear-free. The food and pharmaceutical industries are a case in point, and processes like semiconductor production that require a vacuum can benefit particularly from an abrasion- and contamination-free product transportation system.

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved