Many critical industrial and other applications can benefit from medium-voltage (MV) electric motors, due to their reliability and low total cost of ownership. According to Floris Erasmus, sales specialist – HV motors at Zest WEG, the benefits of MV electric motors include being purpose-designed and well protected. This makes them very reliable, and thus well suited for critical applications where the risk of failure-related disruption must be mitigated.

“Any motor application – from pumps and fans to crushers and conveyors – can present a critical risk if a significant portion of the whole operation relies upon it,” says Erasmus. “In these cases, it is often worth considering the MV motor option in new projects or in circumstances where motors are being replaced.”

While electric motors tend to be categorised as low-voltage (LV) up to about 1000 V, MV motors range from 1000 V up to as high as 33 kV. In the South African market, the upper end of the MV range is usually 11 kV, he says. “MV motors are generally not off-the-shelf, and are rather specially designed for their application.”

The construction of an MV motor is also different to an LV motor. The ‘wire’ used in the windings, for instance, is more like a rectangular bar. Normally covered with mica tape, they make up form-wound coils. “The coils are individually wrapped with thicker insulation to accommodate the higher voltage,” he says. “There is only one turn in a slot, so there is no potential difference between turns; this means that there is less chance of an inter-turn failure or short circuit between coils.”

An important difference in the winding of an MV motor is that it is conducted using vacuum pressure impregnation (VPI) and the use of an epoxy resin. Applying this resin in a vacuum allows all air and moisture to be removed. The absence of air allows the resin to flow more effectively into the spaces between the steel core and the copper winding. The incidence of air pockets in the slot of the stator is where many winding failures in motors begin.

“If resin is not distributed effectively, this can undermine the mechanical strength of the winding,” Erasmus says. “The epoxy resin used in MV motors is very strong compared to varnish.” He highlights that the removal of moisture during the VPI process reduces the possibility of short circuits caused by water particles trapped inside the motor windings.

“Another benefit of MV motors is their low starting and operating current,” explains Erasmus. “The kilowatt rating of a motor – the power it consumes – is a function of the voltage; by raising the voltage, the amperage drawn is reduced.” The starting current of a motor tends to be about six times higher than the operating current, he points out. By reducing the operating current, an MV motor thereby helps to reduce the strain that high starting currents can place on the electrical system in a mine, plant or factory.

The MV option also has a distinct advantage when it comes to the use of variable-speed drives (VSDs). The transformers that are part of the MV motor installation ensure that no extra filters or add-ons are required to achieve near-perfect sine waves. He notes that MV VSDs are also better at disrupting harmonics in the electrical system.

Protection systems on MV motors are an important aspect of ensuring their longevity. Erasmus explains that they are normally electrically protected with a smart relay which is password-protected. This makes it difficult to bypass the overload systems that protect the motor, and prevents the motor from being started under fault conditions. While this protection might slightly increase installation costs, it helps reduce total cost of ownership.

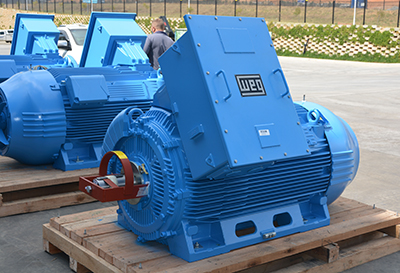

“In terms of our own MV offering, WEG has recently launched its W51 range which includes MV motors,” Erasmus says. “This new range offers improved efficiencies and higher output-to-weight ratios, and the motors are suitable for VSDs.”

Frame availability ranges from IEC 315 to 450 which, with four-pole motors, translates to a range of 132 kW to 1400 kW. The standard range reaches 6,6 kV but motors up to 11 kV can also be requested. The range includes motors for hazardous areas, where there may be gases which are susceptible to ignition.

| Tel: | +27 11 723 6000 |

| Email: | [email protected] |

| www: | www.weg.net |

| Articles: | More information and articles about WEG Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved