All the talk seems to suggest we are heading towards complete digitalisation. But how do you get on this path and what is the right direction for your own company? Keller has over 45 years of experience in the area of recording and processing measurement data. Its service package, which ranges from pressure sensors to the finished web app, helps you find your own way to a customised IoT solution.

Industry 4.0 and smart cities are technology drivers behind the digitalisation of pressure sensors and pressure measuring solutions. The intention and the need to make processes more efficient are at the heart of digitalisation. The path towards digitalisation begins with recording data, mostly with sensors. Pressure sensors also record measured values. For machines or fill levels in containers and tanks, this takes the form of states. For lakes, rivers and groundwater, the levels are measured.

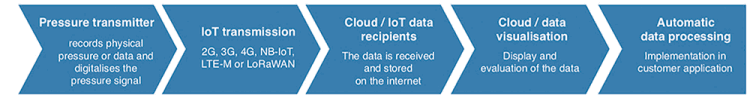

The objects measured are connected to the Internet and save their data to a cloud, with the data mainly being transmitted wirelessly via radio transmission. The latest technologies such as LoRaWAN or mobile communications (NB-IoT, LTE-M) are also used. The data can eventually be retrieved on all possible end-devices such as computers, tablets or mobile phones. This entire Internet environment of and with objects makes up the Internet of Things.

Comprehensive IoT service package

Keller offers a comprehensive IoT measuring system, based on the latest technologies, that allows the user to take an immediate step towards digitalisation, without much effort and at a low cost. Using this solution, no software solutions or hardware need to be created, a working and tested measurement data recording system can be accessed, and no separate, technically advanced training in the technologies is necessary.

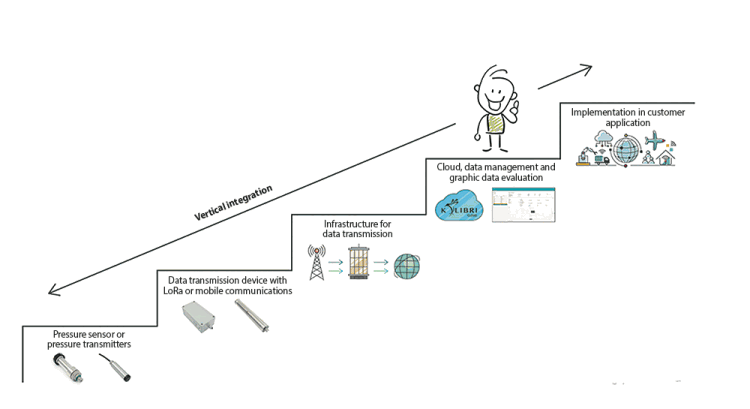

Keller’s measuring system is designed in such a way that each part of the measuring chain has a specific interface. Thanks to the open and well-documented cloud API, the user can incorporate the measurement data processing system into their own information system and therefore start at exactly the point where the greatest benefits of digitalisation are revealed. Keller makes available all individual interfaces so that users have free choice in terms of implementation as to whether they would like to set up the entire system or only parts of it, as required.

How deeply this vertical integration is implemented depends on the application and involves weighing the costs against the benefits. The lowest integration level is defining the pressure sensor signal. Figure 2 shows the individual integration levels from the pressure sensor series 9L up to the Kolibri Cloud web app.

Digitisation of the pressure sensor signal

The pressure sensor signals are processed and digitised using an electronic circuit. This means they are converted into a number (pressure) that can be retrieved via an interface. Other useful information can also be taken from the pressure sensor, in addition to pressure and temperature.

In many cases, too little attention is paid during the initial process considerations to the importance of an accurate, stable and reliable sensor. The sensor that records the data is one of the most important parts of the system, because decisions are made and actions taken based on this sensor.

Remote transmission

Another important part of digitalisation is transmission of the recorded data. Often, sensors are located in places that are far away from the central collection and evaluation point, or they cannot be connected to a local communications network.

The Internet of Things (IoT) is a global network that enables the exchange of data via the Internet. This means that sensor data, for example, that has been generated at different locations around the world can be amalgamated in one system (the cloud). A prerequisite for this function is that the device, the machine or the sensor has access to the Internet. For the measuring solution from Keller, autonomous, battery-operated IoT devices are used that transmit data via various radio interfaces.

One advantage is that these devices can be installed with little effort, as there is no need for cabling and the measuring devices do not have to be incorporated into a company’s communications network. So that the devices and their batteries have a service life of several years, standardised radio technologies (LoRaWAN as well as mobile communications such as 2G, 3G, 4G, NB-IoT and LTE-M) with low energy consumption and a long transmission range of 15 km or more, are used alongside an intelligent, energy-saving electronics system. Whether LoRaWan or mobile communications are used depends on the requirements for the data recording and the type of radio coverage available on site.

Data can be exchanged bidirectionally in both radio systems. Not only does this mean that measured values can be sent from the measuring point to the central collection point (the cloud), but communication from the central collection point to each measuring point is possible too. Communication to the device is used for configuration notifications, which, for example, change a measuring interval from a distance. The communication interface from Keller devices with LoRaWAN (ADT1) as well as mobile communications devices (ARC1) is well documented, and sample software code is available for integration into the customer’s own application.

All devices are designed so that a software update can be installed, for example to account for updates to radio technologies or modifications of wireless protocols. The electronics of the ARC1 mobile communications device for data transmission have a modular design and allow replacement of the radio module in the event of future technology changes, so that the transmission device can be adapted again to the latest mobile communications generation, with little intervention and without having to replace the entire device.

Security

The data is transmitted in encrypted form for LoRaWAN and mobile communications, from the measuring point to the cloud. Current cryptographic processes are used here. The encryption can be stronger for mobile communications as a result of the higher data throughput and the choice of encryption types available.

Kolibri Cloud by Keller offers simple and convenient access to the measurement data with your own personal login and SSL encryption. With the Kolibri Cloud web app, data is available without the need to set up and maintain a database. Measurement data can be displayed in graphical form, and the export function allows you to download your data as Excel or .csv files. Measuring points are effortlessly and efficiently monitored with the integrated alarm system. For instance, a warning can be triggered via email if there is an increase in the water level or a battery is running low.

The cloud software interface (API) allows measured values from another software system to be called up in a standardised .json format via https. This way, the data can continuously be transferred into the company’s own software system, therefore making processes more efficient, which is the goal of digitalisation with IoT. Keller provides software developers with extensive documentation on the API.

| Tel: | +27 10 595 1831 |

| Email: | [email protected] |

| www: | www.instrotech.co.za |

| Articles: | More information and articles about Instrotech |

© Technews Publishing (Pty) Ltd | All Rights Reserved