As the world’s population continues to increase, so too does the need for and consumption of the vital resource of water. According to UN estimates, global water demand is expected to increase by 1% until 2050. Already, 2,2 billion people do not have access to safe drinking water, and this figure is more likely to go up than down.

All the more reason why water treatment, especially recycling, is a globally important issue to ensure people’s quality of life, now and in the future. In total, roughly 1000 cubic kilometres of wastewater are generated each year.

Wastewater treatment has changed a lot since Europe’s first wastewater treatment plant opened in what is now Frankfurt am Main, back in 1882. In addition to established biochemical processes, technical solutions that enable more environmentally friendly and hygienic water purification are also used.

This has also led to an increase in the number of people connected to the wastewater disposal system. The unit used to express the performance of wastewater treatment plants is the population equivalent (PE). The population equivalent corresponds to the amount of biodegradable load that one person puts into the wastewater system, on average, each day, and for which 60 g of oxygen is required over a five-day period. A lot of wastewater is also produced by industry and agriculture.

However, wastewater treatment is only one part of the water cycle. The actual water supply is partly in the municipal administration’s hands and partly in the hands of the private sector. Water supply is also a key part of the municipal administration’s business, although its practical implementation is often subcontracted out to private companies.

Overall, the issue of water must be viewed as a cycle consisting of supply and disposal, which needs to be governed and managed in a holistic manner. As such, the challenges facing municipalities are similar in terms of extraction and disposal: both contain installations characterised by pumps and pipes.

A reliable controller is indispensable when it comes to guaranteeing the fail-safe availability of the plants. Climate change and the accompanying water scarcities have posed a significant threat to water supplies in recent years. In the future, municipalities will have to overcome ever greater hurdles to ensure a reliable water supply. Added to this are problems caused by increased pollution from microplastics, saline wastewater or nitrate in the groundwater.

Due to demographic changes, water suppliers are facing further challenges: there are not enough skilled workers to keep up with growing demands. This situation is addressed with increasingly decentralised control and monitoring of plants using cutting-edge sensor technology and customised software solutions.

Complex systems in use

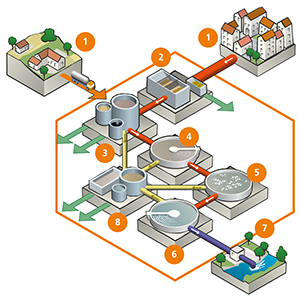

When viewing the process steps of a wastewater treatment plant, as illustrated in Figure 1, it becomes clear just how complex a wastewater disposal system actually is. Water enters the plant via the sewage system (1). During the initial step, i.e., mechanical cleaning (2), a bar screen removes larger impurities from the water, while coarse impurities settle in the downstream grit chamber (3). This step is essential to filter sand, stones or pieces of glass out of the water, as they would otherwise cause damage to the plant components in which further treatment steps take place.

In the primary sedimentation tank (4), the flow velocity is reduced to such a degree that organic matter settles. The resulting sludge is removed directly before being stabilised through mesophilic anaerobic treatment (8). This mechanical purification step is followed by a biological purification step (5). The water is first transferred to the activated sludge process. Through the addition of atmospheric oxygen, aerobic bacteria in the oxygen breaks down wastewater constituents; the nitrogen in the organic compounds is first broken down into ammonia and then oxidised into nitrates by nitrification.

Denitrification then breaks down the nitrates into molecular nitrogen. Once this process has been completed, the wastewater and activated sludge run into the clarifier (6). This is where the activated sludge is separated from the water by changing the water hydraulics; part of it runs back into the aeration tank as return sludge, the rest is discharged as excess sludge and finally fed to sludge treatment (8). The purified water then flows out of the wastewater treatment plant and back into the water cycle (7).

Although this basically completes the water purification process, treatment of the digested products in the wastewater treatment plant still continues. The sludge is thickened and pre-treated in the pre-thickener. This is followed by digestion through mesophilic anaerobic sludge stabilisation before the digester gas is processed and utilised, for example, as an energy source in combined heat and power plants.

Once the digested sludge has been dewatered, it can be disposed of. Today, sewage sludge is generally used as fuel in energy production. Its use in agriculture for fertilisation is declining sharply, not least due to stricter legal requirements to reduce soil pollution caused by phosphate and nitrate.

Depending on the country, individual process steps are subject to different regulations, but plants around the world use comparable processes and procedures, and the associated challenges and problems remain the same.

In order to be able to control the complex process, wastewater (sewage) treatment plants have a control room as a central unit, in which all information or operating states can be queried and process steps controlled. Older plants are operated via programmable logic controllers (PLCs), whereas more modern ones are equipped with process control systems. In both systems, data from the various sensors is transferred to the control room via a fieldbus system.

State-of-the-art plant controllers ensure smooth operation

A state-of-the-art plant controller is important to ensure a continuously smooth process in the wastewater treatment plant, which, like all plants in the water cycle, is categorised as critical infrastructure. Plants in this category must be protected against external influences and failure. If a wastewater treatment plant fails, this can lead to restrictions in everyday life for thousands of people and a risk to the environment. The same applies to the provision of water.

Water treatment plants are also of particular importance, as groundwater is not automatically suitable for human consumption. As in wastewater treatment, complex technologies are used in water treatment plants, and every error in the process means a loss of precious water. This becomes particularly important when there are fewer and fewer staff available in the facilities. The shortage of skilled workers is also affecting the water industry, with fewer young people entering the profession.

The solution is decentralised control rooms in which conditions can be queried very quickly on large screens. The control room allows staff to check sensor data remotely and, as a first step, to evaluate the functionality or the condition of individual plant components – so-called condition monitoring. If this IT-based condition monitoring is continuously operated and evaluated, it enables predictive, demand-oriented maintenance in the next step.

Since age-related deviations between ideal plant conditions and a condition that requires maintenance can thus be detected at an early stage, maintenance measures can be planned in good time. This means that wastewater treatment plants can, at best, be operated beyond the 20 years for which they are designed.

In order to obtain the best possible insight into the plant at all times, it is important to regularly update both hardware and software to the latest state of development. Older plants can also be updated and operated more efficiently through retrofitting. These plants often still feature sensors that are individually wired to the PLC. Conversion to innovative systems such as sensor technology with IO-Link provides the ideal remedy here.

How information from the sensor reaches the IT level

Sensors play a key role in the control of cutting-edge wastewater treatment plants, as they measure various parameters in the pumps, pipes and machines.

This includes distance and conductivity measurements, as well as condition diagnostics.

Sensors can be found at various points in the water treatment process. Position sensors can measure the chain tension in the bar screen, detect the position of pneumatically operated valve actuators, and monitor the longitudinal and circular scrapers. Position sensors also ensure the proper closure of maintenance hatches to guarantee the occupational safety of machine operators and maintenance staff. Flow sensors are used in the mechanical stage to detect the screening washers and the rinsing water in the bar screen, pressure sensors measure the rinsing water, and level sensors can be used in the digestion process.

In the biological purification stage, too, sensors can support the ideal course of the process, thus helping to ensure that nitrates and phosphates are degraded in an energy-efficient manner, and to the required extent. Sensors that observe chemical or physical measurands are used here. In the outlet of the wastewater treatment plant, they can help identify harmful substances, thus allowing staff to take appropriate countermeasures. By monitoring this late step in the process, conclusions can be drawn about the purification quality of the entire plant as well as about any remaining impurities in the outlet of the wastewater treatment plant. This promptly available information enables the plant operator to optimise quality assurance.

Overall, the sensors ensure permanent plant availability. Ideally, sensor application is implemented using IO-Link. Multi-vendor digital communication technology simplifies the installation and replacement of sensors, enabling smooth sensor operation.

Another advantage is that since the data can be easily transmitted both to the PLC and to the IT level – and thus also to a central control room – any malfunctions are reported at an early stage and failure of important plant components is prevented. The sensors which monitor flow, levels, temperature or pressure, for example, are installed directly in the plant. Instead of hard-wired communication with the PLC, however, they are connected to an IO-Link master using a standardised sensor cable with M12 connector technology, which then forwards the data both to a higher-level fieldbus and to the IT system. The IO-Link system has the further advantage that sensor parameters can be set remotely. Thanks to the simple connection technology as well as the low wiring effort, the installation time is reduced by up to 60%.

By using sensor technology, maintenance staff is also informed more efficiently about the respective malfunction, as the manual inspection and monitoring of pumping systems and pipes can be significantly reduced and carried out in a more targeted manner through condition monitoring. Vibration diagnostics via a sensor can be used to monitor drives, lifting equipment, bar screens and pumps.

Vibration behaviour that deviates from the normal condition indicates, for example, foreign bodies that can be removed promptly before they cause damage in downstream processes. Sensors in pumps provide basic monitoring and detect cavitation or dry running. Unbalance and wear are also recognised at an early stage. In a nutshell, the former black box thus becomes a transparent, easy-to-control system.

Overcoming plant-related challenges

Another source of damage that can lead to pump failure is cavitation. The term describes the formation of bubble-shaped cavities in hydraulic applications, which can lead to mechanical damage or destruction during operation. Sensors can be used to permanently check pressure levels and flow rates for limit value violations. Vibrations due to imbalance, shaft misalignments or wear also pose challenges for users.

Vibration sensors, speed sensors and temperature sensors are used in pumps to solve these problems. These systems have the advantage of working completely autonomously. When used accordingly, the sensor data can thus be transmitted directly to the IT level without any losses. This enables continuous remote maintenance in the control rooms. Staff members thus no longer have to manually check the pipe or pump go to great lengths to detect foreign objects by listening to the changed sound of the pump – as was the case in the past.

Maximum plant availability and process reliability is provided by a coherent overall solution, from the sensor and the infrastructure to the IT level. Vibration sensors are then evaluated via diagnostic electronics, which optionally act as a standalone solution or transmit the information directly to the control room. This results in a pump monitoring system that is correspondingly scalable and can be adapted to the respective requirements in the wastewater treatment plant.

Overall, this means that fewer staff are needed. This optimises staff deployment and helps to counteract the shortage of skilled workers. Last, but not least, plant availability is also increased.

Automation solutions for more efficiency in the water cycle

The use of sensors in the supply and disposal of water pays off on several levels.

On the one hand, it counteracts the ever-increasing pressure on staff, as fewer people are needed to monitor the condition of the installed plant components. The work process also becomes more efficient since the sensor data is collected effectively and efficiently in the control room.

On the other hand, sensors can prevent failures that could have serious consequences, especially in critical infrastructures. Using predictive maintenance or condition monitoring, errors are detected and rectified early on. In addition, more information about the machine is made available to users. This concerns not only the machine components, but also the measurement of the water quality in the wastewater and the regulation of the bacteria balance.

As a result, plants operate in a more environmentally friendly manner and the water is of a higher quality. Holistic solutions for the automation and monitoring of plants are therefore a key element for the efficient and sustainable water supply of the future, on which more and more people depend due to increasing changes to the climate.

| Tel: | +27 12 450 0400 |

| Email: | [email protected] |

| www: | www.ifm.com/za |

| Articles: | More information and articles about ifm - South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved