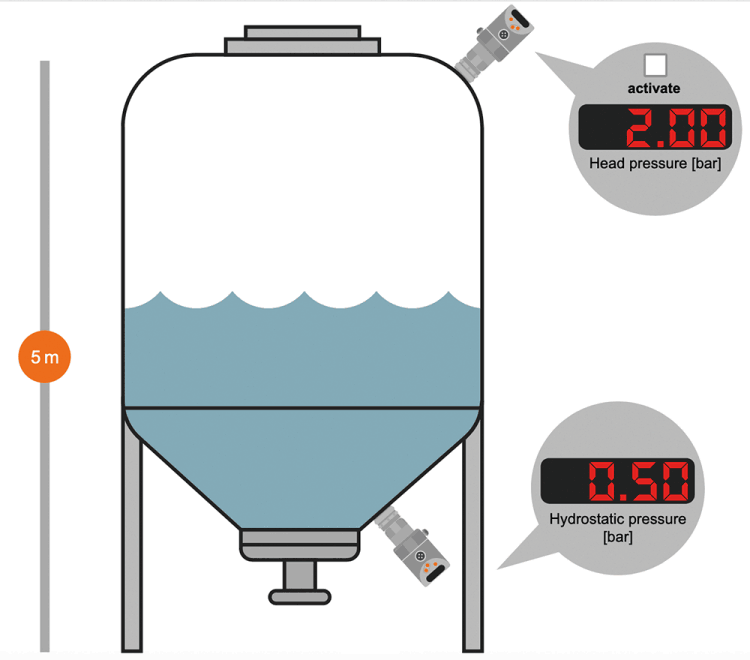

For years, the ifm pressure sensors of the PI series have proven their worth in the food and beverage industry. But even what is successful can be improved upon. Pressure changes can now be visualised via IO-Link in high resolution with approximately 20 000 steps. This is an enormous benefit, especially for hydrostatic level measurement with head pressure. In such applications, the sensor must be designed for a larger measuring range in order to withstand the additional head pressure. With conventional sensors, a larger measuring range reduces the resolution of the pressure detection – this is no longer a problem thanks to the technological advancements of the new PI1xxx range.

What is more, the sensor can detect the medium temperature and transmit it via IO-Link. This means that it is no longer necessary to set up an additional temperature measuring point.

Advantages of the new PI pressure sensor

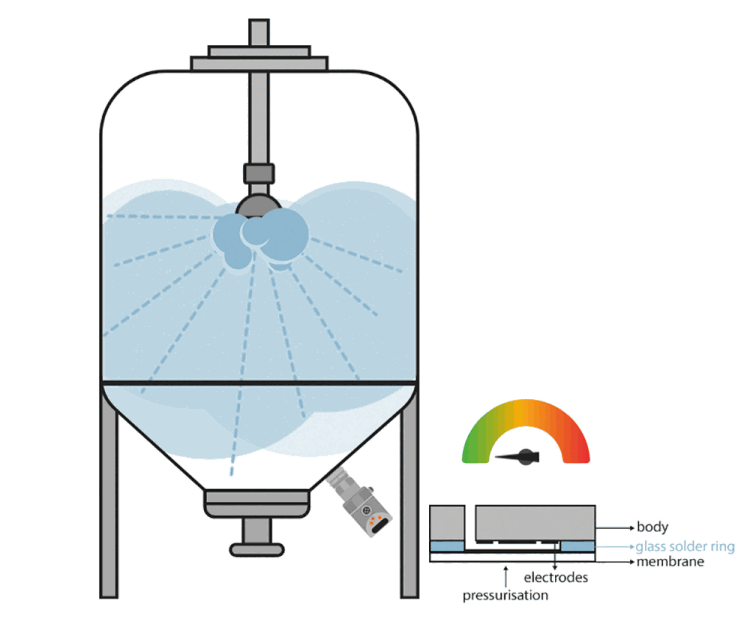

Ceramic measuring cell

The ceramic-capacitive measuring cell consists of a base body, two capacitor layers, a glass solder and a membrane. The capacitor layers on the base body and membrane are similar to a plate capacitor and form a measurement and reference capacitor. When pressure is applied, the distance between the membrane and the base body changes, and this changes the capacitance between the electrodes. This change in capacitance is evaluated and then processed to output an industry-standard IO-Link signal.

The PI pressure sensor has a high-purity ceramic measuring cell. This offers high resistance and long-term stability, even with frequent pressure peaks or overload. In addition, the ceramic is resistant to abrasive media.

Optimised ventilation

The ventilation has been optimised compared to the previous sensors of the PI series. Moisture thus runs reliably off the Goretex membrane if the sensor is mounted with the display facing upwards or downwards.

Flush measuring cell

The measuring cell, which is flush with the process, gives deposits no chance. Only food-grade and maintenance-free materials come into contact with the medium.

High temperature resistance and measurement

Being permanently resistant to medium temperatures of up to 150°C, the sensor can also measure these and output them cyclically via IO-Link.

IP69K ingress protection

Thanks to protection class IP69K, the sensor not only permanently withstands harsh environments, but also meets all the requirements of the food industry.

Typical applications

The pressure sensors of the new PI1xxx series are ideally suited for applications in the food industry – for example in dairies, breweries and many other applications where liquids are used. Pressure measurements in these applications are carried out in tanks as well as in pipes. The numerous improvements of the sensors offer important advantages to the user.

In most cases, beverages are manufactured in individual, highly automated processes that require reliable sensors. They ensure maximum process reliability so that a high-quality product results. Sensors from ifm electronic comply with the required approvals such as EHEDG or 3-A. In addition, they are resistant to clean-in-place (CIP) and steam-in-place (SIP) cleaning processes.

Added value thanks to IO-Link

32-bit IO-Link resolution

The new PI1xxx models, with their 32-bit resolution and approximately 20 000 steps, offer a detailed display even across wide measuring ranges.

Loss-free data transmission

IO-Link enables loss-free data transmission as conversion losses are obviated thanks to digital communication, and external influences such as magnetic fields have no effect on data transmission. Diagnostic data is also provided via IO-Link.

Transparent processes

The current pressure is output precisely with the highest possible resolution via IO-Link. This makes it easy to keep an eye on your process at all times. In addition, the medium temperature is output cyclically via IO-Link.

Easy setup

The pressure sensor can be configured quickly and easily via IO-Link. This is supported by a simulation function, among other things.

Improved technology

Higher resolution, revised design

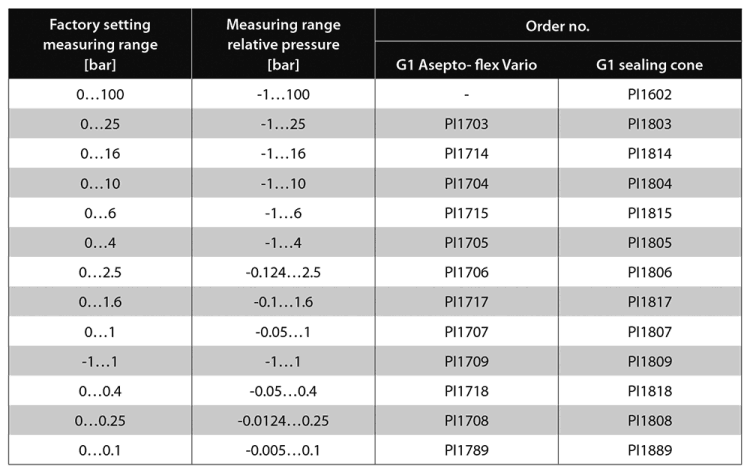

The new pressure sensors, which are available in different measuring ranges from vacuum to 100 bar, communicate via IO-Link 1.1 and offer a resolution of about 20 000 steps. This is especially important for applications where differential pressures are measured and thus only a small part of the measuring range can be used. Temperature compensation has also been improved in the new series.

Even seemingly small improvements to the design of a sensor can have a big impact in the application. For example, the vent hole on the new pressure sensor has been offset by 90° and is now located on the side when mounted conventionally. This prevents condensate, for example, from collecting on the membrane of the vent hole and causing soiling or impairing proper functioning. The PI has also been optimised in terms of user-friendliness: the new operating concept, with three pushbuttons, makes the act of setting parameters much more convenient and thus also faster.

| Tel: | +27 12 450 0400 |

| Email: | [email protected] |

| www: | www.ifm.com/za |

| Articles: | More information and articles about ifm - South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved