When a local metal smelting operation had a requirement to remove manual sampling from its slurry line and replace it with an online density measuring instrument, Allpronix was approached to advise on a solution. One of the requirements was that any proposed online system had to be radiation-free/non-nuclear, due to the associated safety and environmental regulations.

The solution

Allpronix proposed Rhosonics’ slurry density meter (SDM) as a good solution for this measuring task because of its reliable real-time density measurement capabilities. In addition, the meter is non-nuclear, which means it does not pose threats to human health or the environment. This meant no special training of personnel, no need for a radiation safety officer (RSO) on site, and no associated licencing costs.

Rhosonics describes its mission as being to help industry through the provision of sustainable ultrasonic technology that allows safer, more reliable and cost-effective operation, in contribution to a greener and smarter industry.

In the last decade, the company has made significant steps towards becoming the leading supplier for density meters in mining applications through proving the reliability of ultrasonic technology for density measurement based on acoustic impedance. In 2020, the Rhosonics SDM became winner of the ‘Environmental Impact’ category in the mining excellence awards as one of the great achievements and innovations in the mining industry.

The technology

By measuring the acoustic impedance of a slurry, the SDM calculates its density in real-time during the process. The latest sensor is made of stainless steel and ceramic material, which give it advantageous properties. Making use of ceramic materials gives the ultrasonic signal more power than before; also, it is more wear resistant than previous models.

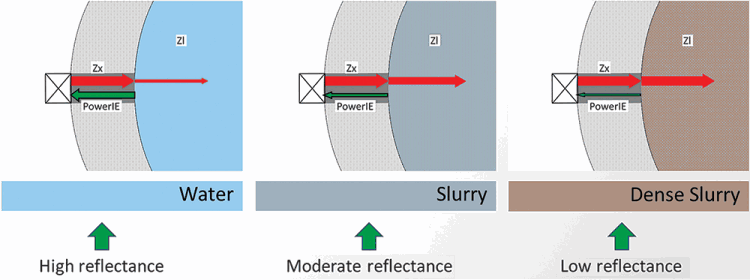

The transducer generates short, highly dampened ultrasonic pulses in the frequency range between 1 and 7,5 MHz. Differences in acoustic impedance of materials causes this acoustic signal to be (partially) reflected. As the density of liquid increases, so does its acoustic impedance, causing a decrease in the strength of the reflected signal (see Figure 1 below). The vibrations of the reflected signal cause the piezo element to send out electric signals, which are then analysed in the device and eventually used for density calculations.

Today, the Rhosonics SDM is a sustainable solution for the mineral processing industry. This ultrasonic measuring instrument is designed to determine the slurry density in real-time to verify the amount of solid content in a liquid. Features and benefits include:

• Reliable results under harsh process conditions.

• Fast delivery times.

• Robust, compact and lightweight.

• Easy installation and calibration.

With more than 800 installations worldwide and more than 10 years of experience in the mining industry, Rhosonics has proven that ultrasonic sensors are suitable for the harshest process applications where typically only radiation-based technologies were applied.

Results

After installation of the Rhosonics SDM, the smelting company has achieved its goal of real-time online density measurement, which has allowed greater control of the process, enabling the production of a more consistent product.

A payback time of approximately two years is anticipated through reduction of labour costs and hours spent on manual sampling. In addition, no extra expenses were required for RSO training or radiation leakage tests.

| Tel: | +27 11 795 9500 |

| Email: | [email protected] |

| www: | www.allpronix.com |

| Articles: | More information and articles about Allpronix |

© Technews Publishing (Pty) Ltd | All Rights Reserved