For a long time, Industry 4.0 was little more than a vision, a desire to bring the productivity, convenience and simplicity that digitalisation offers us in our private lives to the process industry. But now, more and more applications are breathing life into the Industry 4.0 sphere, and the vision is finally becoming a reality. Endress+Hauser fully embraces industrial digitalisation by applying new technology and communications, while leveraging its profound application expertise and know-how. Product innovation and expanding sensor technologies are the core foundation of industrial digitalisation and Industry 4.0.

In the world of open systems, Endress+Hauser remains independent of any particular industrial automation system supplier or architecture, supporting virtually all industrial networking and data model standards, including EtherNet/IP, Profinet, IO-Link and OPC UA. Endress+Hauser actively participates in the latest industry initiatives on topics including structured modular product design, MTP (modular type package) cloud services, and Industry 4.0 for process automation.

The Endress+Hauser Open Integration partner initiative is focused on advancing open, interoperable systems (instead of proprietary solutions) to improve the quality and efficiency of device integration and lifecycle maintenance of control and automation systems. Listening to customers and the need for information standardisation to dramatically lower process automation lifecycle costs became clear, so in 2015 the company took a leadership position by forming the Open Integration partner programme. The fundamentals of the programme are focused on reducing risks and increasing efficiency.

Systems approach

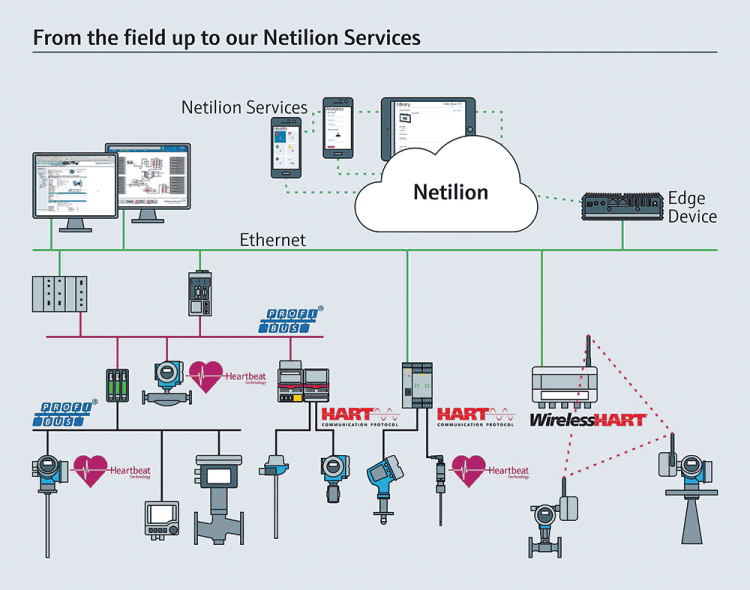

Endress+Hauser innovates its sensor technology with integrated intelligence and communications, understanding the importance of systems design and tools. This has resulted in the development of the Endress+Hauser Netilion IIoT solution platform, an ecosystem combining digital services and system components to improve the lifecycle and asset management, maintenance, and support of measuring instruments and analysers. Netilion enables users to keep track of their installed base, documentation and data management, as well as an instrument’s performance and health status. Netilion includes a free smartphone app that guides the user in capturing field instrument asset data utilising QR-code or RFID tags. It can store images as well as instrument location and accessibility. Critical and quality-relevant information can also be saved and associated with instrument tags. Netilion system components, such as field gates and edge devices, can be used to upload installed base information and create lists of the instruments without requiring interaction with control systems.

The installed base information in Netilion Analytics can then be used to create a digital twin of the system, analysed with the help of dashboards to initiate proactive maintenance measures for critical instruments. Netilion Health can track the condition of the instrument so that other maintenance optimisation measures can be initiated. There are many other features that can be used separately or in concert to improve the management, maintenance and support of instrumentation systems, regardless of instrument or vendor.

Edge device

The FieldEdge SGC500 connects field devices to the Internet, and Endress+Hauser IIoT Netilion supports communication standards including HART, WirelessHART, Profibus and, in combination with gateways, EtherNet/IP. HTTPS data transfer with end-to-end encryption and authentication according to the OAuth 2.0 standard guarantees a highly secure connection to the Internet. In addition, data can only flow in one direction, from the field device to the Internet.

Micropilot FWR30 level sensor

An example of innovation is the Micropilot FWR30 level sensor designed for remote and mobile applications. Applications, including installation on mobile transport containers worldwide, continuously measure and transmit the level of liquids and solids. The sensor operates on the principle of free-radiating radar and is designed exclusively for operation in an IIoT environment. The device communicates wirelessly with the Internet without a gateway, using LPWAN, Narrowband Internet of Things (NB-IoT), and LTE-M or 2G cellular standards. Netilion Inventory or Supply Care Hosting can be used to display the measured values on various end devices.

Power management in the device enables battery life of up to 10 years or more. The integrated GPS positioning function allows the instrument to be located from anywhere at any time. Measured values and positions can be displayed on a map via digital services. Installation and commissioning, in particular setting up the connection to the Internet, are simple and can be completed in just a few minutes. Level measurement is performed using reliable and accurate 80 GHz radar technology. The maximum measurement deviation over the entire measuring range is less than 10 mm. Radar technology provides a further advantage with non-conductive tank walls. Mounted on plastic tanks, the sensor can measure through the wall without coming into contact with the medium.

Conclusion

Founded in 1953, Endress+Hauser continues as a pioneer and innovator in sensor technology, serving customer needs for quality measuring instruments and low lifecycle costs.

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved