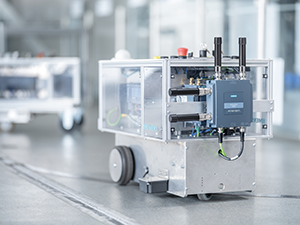

The Scalance MUM856-1 – the first industrial 5G router from Siemens – is available now. The device connects local industrial applications to public 5G, 4G (LTE) and 3G mobile wireless networks. The router can be used to monitor and service plants, machines, control elements and other industrial devices via a public 5G network. In addition, the device can be integrated into private 5G networks. The Scalance MUM856-1 therefore supports future-oriented applications such as mobile robots in manufacturing, autonomous vehicles in logistics, or augmented reality applications for service technicians. Thanks to a robust IP65 housing, the router can also be used outside the control cabinet, for example, under harsh conditions in production or in outdoor facilities in the water industry.

To ensure the powerful connection of Ethernet-based subnetworks and automation devices, the router supports Release 15 of the 5G standard. The device offers high bandwidths of up to 1000 Mbps for the downlink and up to 500 Mbps for the uplink – providing high data rates for applications such as the remote implementation of firmware updates. Thanks to IPv6 support, the devices can also be implemented in modern communication networks. Various security functions are included in order to monitor data traffic and protect against unauthorised access: for example, an integrated firewall as well as authentication of communication devices and encryption of data transmission via VPN. If there is no available 5G network, the device switches automatically to 4G or 3G networks. The first release version of the router has an EU radio licence; other versions with different licences are in preparation. With the Sinema Remote Connect management platform for VPN connections, users can access remote plants or machines easily and securely, even if they are integrated in other networks. The software also offers easy management and configuration of the devices.

Successful use of prototypes for private 5G networks

Besides connectivity to public networks, Scalance MUM856-1 also supports integration into private local 5G campus networks. Siemens is testing this use case in its own Automotive Showroom and Test Centre in a prototype of a standalone 5G test network, which is based on Siemens components. The 5G infrastructure used here comprises a 5G core, a distributed unit and several radio units. Siemens has also built another prototype of a private 5G infrastructure in its plant in Amberg, and the Karlsruhe plant will be equipped soon. In these systems, Siemens is relying exclusively on its own independently developed products and solutions. In addition, it is currently implementing private network technology for a 5G campus network with a focus on industrial use in one of the Deutsche Messe exhibition halls in Hanover. The network can be used by exhibitors during trade shows and, outside of trade show times, can be used by companies for tests and field trials.

Background information

In industry, in addition to the need for local wireless connectivity, there is increasing demand for remote access to machines and plants. In these cases, communication is usually over long distances. Public mobile networks can be used to access devices that are located at a considerable distance, for example, in other countries.

In addition, service technicians can connect to the machines they need to service via the mobile network while on the go. Public 5G networks are therefore an important element of remote access and remote servicing solutions. They can be used, for example, to provide users with high bandwidths in urban areas with small radio cells and high frequencies. In rural areas, radio cells have to cover a large area, which is why lower frequencies are used. Particularly at the edges of radio cells, there are often significant losses in terms of both the bandwidth and stability of the communication connection. And it is exactly in these remote areas where stable bandwidth transmission is required for remote servicing or video transmission, for example, for water stations. With innovative 5G communications technologies, considerably more bandwidth with greater reliability is available at the edges of radio cells and the average data rate for users within a radio cell increases.

| Tel: | +27 11 652 2000 |

| Email: | [email protected] |

| www: | www.siemens.co.za |

| Articles: | More information and articles about Siemens South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved