Omniflex has recently launched a new set of Maxiflex CPUs - the T1 and now the T2. These CPUs are intended for data acquisition and telemetry applications. They require no user programs when used for data acquisition or telemetry application and are designed to be just plugged straight in, field wiring connected, and power switched on. All I/O is scanned automatically and I/O status assembled into a data interchange table (DIT).

For digital inputs and standard analogs the input status requires no configuration at all, however, temperature inputs like thermocouple and RTD require the sensor type to be configured providing input values in engineering units of °C or °F. Scaled analog inputs can also be catered for - eliminating the need for the HMI to do any scaling to engineering units for 4-20 mA loops from the field. Adding I/O to the system has been made simple - by just plugging in the new modules while the system is live (hot plug-in) and then plugging in the detachable wire terminals from the field. The new field I/O status is added to the DIT automatically.

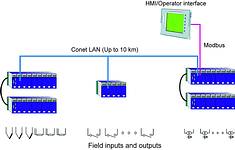

Configuration is easily performed with the free Windows-based software package called OmniSet (Figure 1) and a serial cable available from Omniflex. Simple selection of pull down options allows the user to configure the CPU completely. This configuration includes the ability to create multi-drop telemetry systems using the Omniflex CONET local area network up to 10 km on twisted pair cable. Configuration can also be done via the HMI, if so desired, making a neatly integrated system controlled exclusively from the HMI stations.

The HMI is connected to the Maxiflex T1 or T2 CPU via its auxiliary serial port - which can be set to communicate using Modbus Protocol, one of the standard protocols on every HMI. The HMI then has access to any of the DIT registers on the CPU. In fact, if a Conet local area network is used, any data from the network is also accessible to the HMI - not just the local node. Multiple HMIs can also be connected to the network in the same fashion, reading the same or different data from the network. Outputs may also be generated from the HMI to activate plant devices.

Windows-based Utility OmniSet for configuration Maxiflex provides a cost effective solution to HMI front ends and simplifies the field I/O systems by eliminating the need to write time-consuming application programs for data acquisition or telemetry. Maxiflex I/O systems cover analog inputs, voltage, current, thermocouple, RTD and digital inputs, potential free and voltages up to 200 V d.c. series contact chains and pulse inputs up to 50 kHz.

Interfacing to third party RS232 or RS485 devices is a speciality with analytical devices like gas chromatographs, gas analysers, intelligent circuit breakers or substation energy metering equipment, etc. Given the communication protocol, Maxiflex will communicate with any of these devices. Figure 2 shows the Maxiflex I/O system for HMI display.

For more information contact Omniflex Automation Products, 031 207 7466, [email protected], www.omniflex.com

| Tel: | +27 31 207 7466 |

| Email: | [email protected] |

| www: | www.omniflex.com |

| Articles: | More information and articles about Omniflex Remote Monitoring Specialists |

© Technews Publishing (Pty) Ltd | All Rights Reserved