The tank farm environment, being a hazardous area, presents a number of challenges to field equipment and in particular monitoring and control instrumentation. Limited by hazardous area requirements and long distances, data acquisition is often a problematic and expensive exercise requiring many cable runs to collect data at every tank.

Omniflex has the Maxiflex range of products and is no stranger to the petrochemical industry and data acquisition from hazardous areas. Maxiflex combines data acquisition and telemetry applications into one 'programless' environment. All that is required is plugging them in, connecting field wiring and powering up.

All I/O is scanned automatically and I/O status assembled into Data Interchange Table (DIT) (See inset picture). For digital inputs (pressure/level switches, valve status etc) and standard analogues (levels, valve position etc) the input status requires no configuration at all, however temperature inputs like thermocouple and RTD require the sensor type to be configured providing input values in engineering units of °C or °F. Scaled analog inputs can also be catered for, eliminating the need for an HMI to do any scaling to engineering units for 4 to 20 mA loops from the field.

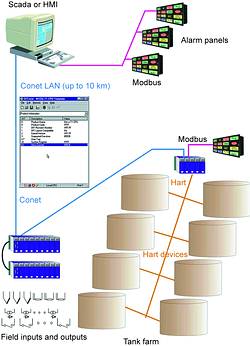

Many field devices like pressure, flow and level transmitter are fitted with Hart communications, Maxiflex has added Hart interface modules to its range for this purpose. Adding I/O to the system requires just plugging in the new modules and connecting the detachable wire terminals from the field. The new field I/O status is added to the DIT automatically. Configuration is easily made using a free Windows based software package called 'OmniSet' - and a serial cable available from Omniflex. Simple selection of pull-down options allows the user to configure the Maxiflex CPU completely. This configuration includes the ability to create complex multidrop telemetry systems using the Omniflex CONET Local Area Network up to 10 km on twisted pair cable. Configuration can also be done via a scada HMI if so desired, making a neatly integrated system controlled exclusively from scada stations.

Outstations, which may be up to 10 km away from the scada or HMI, can be configured from a PC connected to the network. The Conet local area network may be run into hazardous areas using Zener barriers at entry/exit points. The usual loop calculations apply.

Annunciation of alarms is simply a connection from the Maxiflex CPU via its auxiliary serial port which can be set to communicate using Modbus protocol, to an enunciator with visual and audible alarms. Alarm enunciators may also be utilised from the Modbus port to provide alarms and status indication within the tank farm or at the control room.

Maxiflex provides a cost-effective solution to Tank Farm applications as it simplifies the field I/O systems by eliminating the need to write time-consuming application programs for data acquisition or telemetry, local alarm panels (enunciators) can be added and conventional field instrumentation can be mixed with new technology devices like Hart transmitters. Maxiflex I/O systems cover analog inputs, voltage, current, thermocouple, RTD and digital inputs, potential free and voltages up to 200 V d.c. series contact chains, pulse inputs up to 50 kHz. Interfacing to third party RS232 or RS485 devices, analytical devices like gas analysers and Hart enabled devices. The Conet Network Topology can be used as a BUS, star or mixed configuration allowing complex networks to be configured all on low-grade cables with the tank farm environs.

| Tel: | +27 31 207 7466 |

| Email: | [email protected] |

| www: | www.omniflex.com |

| Articles: | More information and articles about Omniflex Remote Monitoring Specialists |

© Technews Publishing (Pty) Ltd | All Rights Reserved