Movigear units for new bottling line

September 2018

Motion Control & Drives

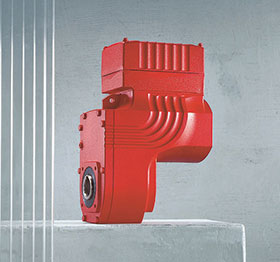

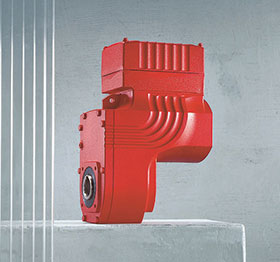

SEW-Eurodrive South Africa has delivered 67 Movigear mechatronic integrated drive units to a major glass-manufacturing facility in the Western Cape in a record turnaround time of six weeks. Components were sourced from Germany, while the units were assembled in Cape Town. “The order for the Western Cape facility follows on from work that the company undertook for its customer in Gauteng about six years ago,” explains sales engineer Sean Tibbott.

The fact that the original bottling line has been running successfully on Movigear units to date means that the technology is tried-and-tested. “That essentially paved the way for the Western Cape expansion, in keeping with the general industry trend of energy-efficiency and cost-saving,” highlights Tibbott. The project is a good benchmark for mechatronics in general, and Movigear in particular.”

“Industry has tended to shy away from this technology in the past, mainly due to a lack of understanding on its part,” reveals sales manager, Clive O’Reilly. “However, major customers such as this have not only assisted us make inroads into important markets such as food and beverage, but have raised the profile of mechatronics in general.”

A challenge for SEW-Eurodrive South Africa is to educate the engineering community about the benefits of mechatronics, and in particular, its contribution to the lowest total cost of ownership. “Our practical approach to the issue of raising awareness and providing fact-based figures is to install a Movigear unit for a trial period, and then to measure and compare the power consumption. The energy saving is dramatic, which has a significant impact on the investment decision.”

SEW-Eurodrive South Africa is fast establishing itself as a mechatronics leader in the country due to its local manufacturing capability and its technical support. “If you look at some of our competitors, none of their units are even repaired locally, whereas we not only have the spares stockholding and necessary expertise, but we offer a 24/7 aftermarket service as well,” says Tibbott.

Another factor giving Movigeaer an edge in the local market is that it is available in four variants, increasing its adaptability to different plant layouts. “This extends our flexibility considerably to respond to customers’ diverse requirements and applications. In addition, the Movigear units are ideal for corrosive environments or those where strict hygiene standards are applicable,” Tibbott concludes.

For more information contact Jana Klut, SEW-Eurodrive, +27 11 248 7000, [email protected], www.sew-eurodrive.co.za

Further reading:

Novel bearing steel next generation of aeroengines

SKF South Africa

Motion Control & Drives

SKF continues to re-imagine intelligent and clean rotation with the development of an innovative temperature-resistant, corrosion-tolerant steel called ARCTIC15 designed for aeroengine bearings.

Read more...

Products from maxon

Motion Control & Drives

A wide range of new products is available from motion control specialist, maxon. with a diverse technology portfolio ranging from highly integrated robotic actuators to powerful servo drives and controllers.

Read more...

Actuators for precise hexapod movements

Motion Control & Drives

Aerotech, manufacturer of high-performance motion control and automation systems, is expanding its Automation1 platform. These compact hexapod devices enable the complete integration of six-axis motion systems into existing control

Read more...

SEW-EURODRIVE service centre transforms future of drive repairs

SEW-EURODRIVE

Motion Control & Drives

In a momentous step for the local industrial gearbox and drives market, SEW-EURODRIVE South Africa has formally opened a new service and repair facility alongside its headquarters in Aeroton,

Read more...

Strategic system upgrades beat mining obsolescence and drive productivity

Motion Control & Drives

Mining operations are under constant pressure to maintain output while controlling costs. One persistent challenge continues to confront the industry, knowing when and how to upgrade aging systems before they become a liability.

Read more...

Precision meets performance: The ELGD Axes Family from Festo

Festo South Africa

Motion Control & Drives

Festo has introduced the ELGD axes family, engineered for the demands of future-focused industries. With cutting-edge guide technology, exceptional rigidity and high load capacity, these axes deliver more performance within the same installation footprint.

Read more...

Condition monitoring in hazardous areas

SKF South Africa

Motion Control & Drives

SKF is further strengthening its condition monitoring offer portfolio by a newly developed hazardous area version of its Microlog Analyzer dBX portable vibration analyser.

Read more...

Rip-and-ship solution speeds up nuclear decommissioning project

Motion Control & Drives

When removing steam generators from decommissioned nuclear reactor buildings, the most economical method is to remove them in one piece. Mammoet was commissioned by Framatome to support with the removal of four steam generators from PreussenElektra’s Nuclear Power Plant Unterweser in Germany.

Read more...

WearCheck turns the focus on friction modifiers

Wearcheck

Motion Control & Drives

One of the most important features of a lubricant is the reduction of friction between two surfaces.A dditives like friction modifiers are added to perform this function. Wearcheck turns the focus on friction modifiers

Read more...

SEW-EURODRIVE transforms drivetrain uptime

SEW-EURODRIVE

Editor's Choice Motion Control & Drives

The DriveRadar IoT Suite from SEW-Eurodrive is an ideal solution for industrial condition monitoring. This powerful ecosystem of intelligent sensors, edge devices and cloud-based analytics ensures that customers have full visibility and control of their operations.

Read more...