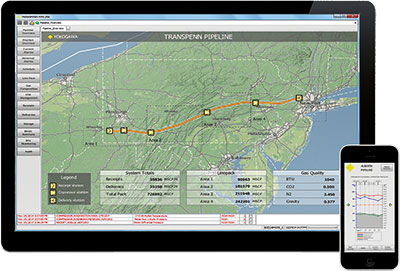

Yokogawa has announced the release of FAST/TOOLS R10.03, the latest version of a web-based real-time operations management and visualisation software solution that scales perfectly from a small and hybrid scada to an integrated enterprise operations and engineering framework – thus enabling higher levels of application portability, modularisation, and standardisation that will help customers derive maximum value from their investments over the entire system lifecycle.

Driven by factors such as IoT, Big Data, analytics, and the Cloud, a digital transformation is underway that is leading to the convergence of information, operational and engineering technologies (IT, OT and ET) in unmanned, remote-controlled, and other operations that go way beyond what has traditionally been possible with DCS and scada solutions. To benefit from near real-time transaction processing and other capabilities that already are well established in the IT domain, a growing effort is being made to achieve seamless integration and convergence with the OT domain. As production and delivery cycles shorten and require greater flexibility, the instant sharing of real-time data on operational capacity and conditions for the purpose of production/maintenance planning and forecasting become critical factors for a company’s bottom line results. A modern open scada platform should be able to bridge the legacy gaps between the IT and OT domains by leveraging OPC Unified Architecture (OPC UA), extensible mark-up language (XML), and direct database interfaces. By simplifying operations, automating activities, and enhancing the user experience, capex can be reduced.

Recognising that most enterprises will take a hybrid approach in their management and control solutions, Yokogawa continues to pursue innovations that will ensure its customers are able to transform their data into meaningful information and get the most out of their investments. This release includes new functions that provide greater transparency by integrating multi-tier architectures and enabling global access to and sharing of a variety of resources.

Main features

FAST/TOOLS R10.03 offers significant enhancements that improve operator efficiency, data processing, application usability, security, and configuration, thus enabling customers to tailor their applications to best fit their work methodologies. It supports the digital industrial ecosystem with open information models that simplify and enhance sub-system integration and diagnostics and enable leaner and flatter architectures. This is done through (cloud-based) virtualisation solutions that are managed as a single system.

1. High-performance ISA101-based HMIs

To help customers implement a more effective HMI strategy a symbol library has been developed that is based on the concepts embodied in the ISA101 standard, designed to promote a consistent approach in the development and implementation of effective HMIs for manufacturing applications, particularly in the process industries. Based on this, end users, automation suppliers, and system integrators can create more effective HMIs that lead to higher productivity and a safer operating environment. ISA101 takes a lifecycle approach to effective HMI management and seeks to identify, define, and address the different needs that arise across this time span. Templates and object-oriented structures created using this library are key elements in these high-performance HMIs.

2. Information model (objects in objects)

The requirement for enterprise-wide process automation solutions is driving the need for ways to make sense of an ever increasing volume of data. For that purpose, Yokogawa has implemented an information model (tree) that allows for process hierarchies and has expanded its solutions by enabling objects within objects. This reduces engineering costs by simplifying the use and re-use of templates.

3. Enhanced DCS integration

System integration is a key development strategy that provides users the best experience from an operations, engineering, and maintenance perspective. As boundaries continue to blur in the automation landscape, Yokogawa is driven to bridge environments and create the ultimate hybrid approach by emphasising integration. With significantly enhanced DCS integration tooling made possible through the support of additional function blocks and hierarchical naming, further support is provided for the transparent integration of Yokogawa’s DCS (the Centum integrated production control system) at the enterprise and scada levels.

4. New table component function

As part of its vision to help people unlock actionable insights from data, Yokogawa has included a new table component function that converts historical data, audit trails and other data sets to a user-friendly tabular format. This allows operators to perform quick cross-category spreadsheet queries of data. Transparency is improved by allowing these tables to be queried and directly reported in native graphics.

Yokogawa will keep working to improve its entire range of solutions and services, including FAST/TOOLS, with the aim of ensuring safe and highly efficient operations over the entire lifecycle of its customers’ facilities.

For more information contact Christie Cronje, Yokogawa South Africa, +27 (0)11 831 6300, [email protected], www.yokogawa.com/za

| Tel: | +27 11 831 6300 |

| Email: | [email protected] |

| www: | www.yokogawa.com/za |

| Articles: | More information and articles about Yokogawa South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved