When speaking about IoT or IIoT, everyone has a visual in their mind and that view is very different and far apart. Some believe that IoT is an Ethernet IP layer-based communication. Others look to a decentralised I/O with connectivity of the Internet. Neither is incorrect.

The Internet of Things (IoT) is the network of physical devices, vehicles, buildings and other items – embedded with electronics, software, sensors, actuators, and network connectivity that enables these objects to collect and exchange data. (Wikipedia)

Now let’s talk about the hardware and concepts in the market. Globally, companies are putting out a great word for the technology and how things could operate, but when you look further into this, only concepts exist with very little hardware, and even less in operation. A second facet to this is the retail market players wishing to introduce their solutions into commercial / industrial applications without an understanding of the needs.

One layer above, their hardware manufacturers have standardised on a single platform cloud solution for display of data which is bound by the parameters set out in their webview. Great for an off-the-shelf, but limiting when not designed in accordance with market sectors, and even more limiting when you wish to offer this as part of a solution to your client base.

Then throw the future direction of technologies like Industry 4.0 into the equation and this leaves the decision markets lost on which direction to go.

Solution. . .

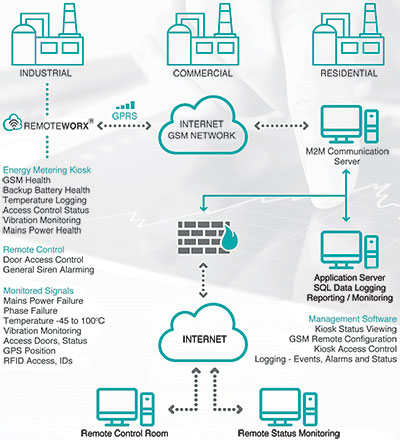

Remoteworx, designed and developed by engineers who have the knowledge and understanding of market needs for both hardware and software applications. Considering both horizontal and vertical markets, the Remoteworx box allows the user extreme flexibility with the advantage of being able to connect the device in any area, connected to almost any platform (WiFi, Ethernet, GSM/3G, LoRa, Sigfox, etc). Through the connectivity of the Internet, Remoteworx is then able to publish data to any and every platform available, whether it be existing (even scada), new or just a webview for visual information. Scada suppliers have the easy integration of the Remoteworx with OPC functionality.

Having all of this in one box allows the user of Remoteworx the ability to connect almost anything needed for integration of one point or many. Should the data carrier have a glitch, the on-board logics will store the data to allow it to be sent at a later stage once connection resumes. For mobile applications or asset management, on-board GPS functionality allows for easy tracking and placement of each device. Further security functionality has also been tested to allow for the integration of RFID and keypads for access and control.

After taking the time to read through the IoT which will not only change our lives, but make them simplified, what can we conclude from this? Input data now has the ability over multiple platforms, through seamless integration to be displayed in any format needed to consolidate information at a central point to make a calculated decision and have control, globally.

So the big question is around what data can Remoteworx provide? Remoteworx is equipped with the following key features:

• Digital inputs: 6x opto-isolated 12 VDC or dry contact.

• Digital outputs: 4x relay 12 VDC 2 A, 2x relay dry contact 2 A.

• Analog inputs: 4x 0-10 VDC or 4-20 mA.

• Real time clock: GPS based.

• Temperature sensor: -40 to 125°C.

• Vibration sensor: adjustable.

• Line voltage monitoring: 3-phase 100 to 380 VAC.

• Frequency measurement: line frequency 50 Hz.

• RFID: HID, RFID interface (Wiegand protocol).

• Communication interfaces: RS-485, GSM, Ethernet, WiFi and ZigBee.

• USB Port: PC connection for diagnostics.

• Storage: Onboard SD card (4 Gb).

For more information contact Remoteworx, Mark Dilchert, +27 (0)82 456 0902, [email protected], www.remoteworx.eu

© Technews Publishing (Pty) Ltd | All Rights Reserved