End-user details

Name: Leon Venter

Designation: Production Manager

Company: Opti Feeds

Phone: +27 (0)18 632 4053

E-mail: [email protected]

SI details

Name: Pieter Reichert

Designation: Principal Technical Consultant

Company: Business Connexion Industrial Solutions

Phone: +27 (0)12 665 1700/2/3

E-mail: [email protected]

Product details

Product names and versions: Adroit Smart SCADA Version 8.3

Vendor: Adroit Technologies

Phone: +27 (0)11 658 8100

E-mail: [email protected]

URL: www.adroit.co.za

Application details

Location: Opti Feeds, Lichtenburg, North West Province

Industry: Food and beverage

Project start date: 2013-08

Project end date: 2014-08

Application: Batching and process control of animal feed manufacture

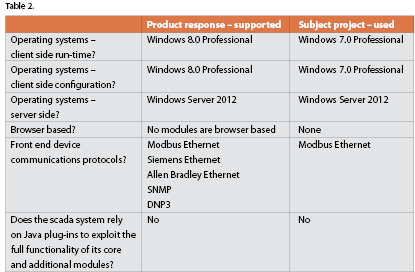

Server OS: Windows Server 2012

Client OS: Windows 7.0 Professional

Application statistics

Tag count: 4308 PLC tags

Updates per day: Approx. 12 400 000

Disk space for one day’s updates: 8 MB

Physical I/O count: 3508 * Digital; 580 * Analog

Front ends: Schneider Premium PLC with remote I/O LS PLC 220 Tags

Licences:

1 * Adroit 8.0 Master Server 2500 SP

1 * Adroit 8.0 Standby Server 2500 SP

6 * View Clients (Design and Runtime)

1 * Alarm Management and Analysis

Scada configuration man-hours: 1920 hrs

End–user responses

General

Q: Briefly describe the application including information on any pre-existing control system.

Opti Feeds has been using an Adroit 6.0 SCADA Classic solution for many years. The switch to Adroit 8.0 Smart UI was made to allow for greater flexibility and more custom programming functionality.

Q: What was the primary motivation for the project?

The previous system relied on numerous scripts to achieve control and required constant input of values by the operations staff. The main purpose of the upgrade was to eliminate all scripting.

Q: What were the main goals established for the project?

1. Reduce operator input into the system.

2. Integrate with SYSPRO for product ordering and recipe handling.

3. Eliminate scripting.

Q: In the procurement decision making process what were the primary considerations that influenced the product selection?

There was an existing Adroit Classic installation. The Adroit Smart UI was selected because of its powerful database/recipe handling and simple MES integration.

Q: What Project Management principles and/or methodologies did you employ as end-user to mitigate risk, ensuring the project came out on time and within budget?

Adroit 8.0 Smart UI SCADA was implemented in parallel with the existing Classic UI system. This methodology ensured that unnecessary downtime was avoided and that process components were kept in place and functioned as normal.

Licensing, maintenance and support

Q: What upgrade agreements are in place for this application?

A Service Level Agreement with remote support, and a Technology Agreement on the scada software.

Q: How is after-sales support handled on this application?

This is provided via regular site visits and remote support by SI. Telephonic support of the scada product is available free of charge during office hours.

Q: Do you have a documented process in place to manage, test and install OS and scada system software patches?

Updates and patches are first tested by the SI in a simulated environment before being deployed to the production system.

Integration, reporting and archiving

Q: Is the scada system integrated onto an intranet or the Internet?

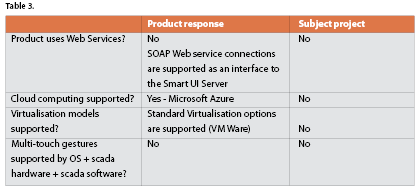

Yes. The system allows for remote SLA support across a VPN to the SI, and tablet connectivity across the LAN for the end-user.

Q: Is the system integrated with an MES / ERP or other management reporting or control system?

Indirectly. Data is shared with SYSPRO using a SQL staging table.

Q: Do you run the scada in conjunction with any other third-party application software?

Yes. In conjunction with in-line packers, post pallet application systems, micro-dosing scales and weighing systems.

Q: Does the application include data archiving / historian capabilities with an historical data reporting system?

Yes. SQL 2008 R2 was used. The built in DataLog and DBAccess agent in the scada are used for logging, inserting, updating, selecting and retrieving data.

Maintenance, reliability and asset optimisation

Q: Have any production benchmarking tools been configured as part of the scada system?

Yes. Target and actual values are displayed on all batching KPAs (Key Performance Areas).

Mobile device support

Q: Are you currently using tablets, mobile phones or other smart mobile devices to interact with the scada system?

Yes. A tablet for maintenance troubleshooting.

End-user conclusion

Q: What was the predominant feature (or features) that made you decide to purchase this scada product over all others for this application?

Openness, flexibility and local support.

Q: What was the most significant change that you implemented in scada engineering practice / technology in this project?

The scripts in the previous system were difficult to troubleshoot and maintain and caused delays in production. These were superseded using standard PLC and scada functionality within the newer Adroit.

Q: What single operational feature most impresses you about the product now that it is in operation?

Bi-directional data base handling between SYSPRO and Adroit 8.0 eliminated all set-point inputs from the operators and thus removed potential input errors.

Q: What impresses you most about the architecture?

The small hardware server footprint for the scada application, where a single server is used for alarming, logging, trending, and scanning to PLCs, thus reducing overall costs.

SI responses

Project details

Q: What tools were used to minimise the man-hours taken?

The standard bulk configuration tools available in the scada

Q: What human factors were taken into consideration as principles or development standards in the HMI design process?

The existing design aspects, with which the operators were familiar, were carried over from the previous scada and requirements for user input were reduced.

Q: For the graphics development process did you use standard library images, or did you have to draw images from scratch?

Mainly from scratch but where relevant standard library images were utilised.

Q: How would you describe the library of graphic images?

Comprehensive.

Q: Did you use any ‘special’ images?

Images from CAD drawings were used.

Q: What alarm management standards or best practices were adopted in configuring the scada system alarms?

EEMUA 191 and the Adroit best practices document were used as guidelines.

Q: What are the key physical communication layers and communication protocols employed in the system?

Ethernet over fibre and copper, wireless 802.nnn and Schneider FIP I/O.

Q: What is the network speed and com-munications medium of the slowest link in this project’s scada network?

10 Mb/s wireless communication.

Q: What is the network speed and communications medium of the fastest link in this project’s scada network?

100 Mb/s fibre communication.

Q: What levels of redundancy are incorporated in this scada application?

An Adroit Hot Standby Server was implemented for redundancy at the Agent Server level.

<i<>Security and data protection</i>

Q: How have authentication, authorisation and role management been configured?

Administrators, managers, maintenance and operator groups were configured on the control domain.

Q: What intrusion detection has been incorporated on the plant network(s) on which this scada system exists?

Intrusion detection is provided via AVG antivirus.

Q: What configuration backup and data archive backup methodologies have been adopted?

Configuration and data backups are performed monthly and on change.

Maintenance, reliability and asset optimisation

Q: What steps were taken to address main-tenance, reliability, asset optimisation and/or continuous improvement aspects relating to this system?

Adroit SCADA SMS functionality is used for maintenance warnings on priority alarms.

SI conclusion

Q: What impresses you the most about the engineering / configuration aspects of the product now that it is in operation?

The richness and power of the Smart UI IDE.

Q: How would you rate the ease of use of the historical reporting system?

Extremely easy to use based on scada trending from SQL supported as standard via the DBLog and DBAccess agents.

Vendor responses

Product

Q: Vendor comments on product / modules?

Adroit 8.3.1.1 Smart UI is the latest released scada version from Adroit Technologies.

Operating systems / VMware

Licensing, maintenance and support model

Q: What sort of licensing agreement options are offered?

Core scada modules and most of the 100+ drivers shipped are covered under one licence. Separate licences are required for design and view clients. Redundancy is charged at a percentage of the master server. Alarm management and analysis, OEE/KPI and M2M functionality are purchased separately as modules.

Q: Are licences sold outright or subject to periodic (e.g. annual) renewal?

The scada licence is a once-off purchase for a particular version (e.g. Version 7 or Version 8.0).

Q: What upgrade agreements are offered?

A non-compulsory Technology Agreement, which is renewable annually, is available and provides for the latest version of the product. A Technology Agreement (TA) provides for the latest version. Updates (e.g. minor version 7.10 to 7.11) are supplied at no cost and can be downloaded from the Adroit website. If there is no TA in place a percentage is charged based on the number of versions to be upgraded.

Q: What after-sales offerings iro support and maintenance are available, and which technologies are used to deliver them?

Telephonic support during office hours is available free of charge. Off-site support is covered under Adroit standard rates or customisable Service Level Agreements. Our 50+ registered system integrators also offer support and maintenance options. Training is offered in-house or on-site.

Q: Do you have a documented process in place to manage and test OS patches and to release scada system software patches?

A standard internal testing procedure is used to verify and test applicable updates and patches as far as possible.

Technology incorporated

Q: What new technology has been introduced into the product in the last 12 months?

21CFR11 security features, additional free reporting capability, enhancements of the object based model to support OEM capability, M2M protocol extensions and many user-driven enhancements.

Integration and reporting

Q: What generic and/or product specific interfaces does the product have iro well-known MES packages?

OPC, currently busy with OPC UA, direct database interfacing, VB.NET scripting.

Q: What native historical data reporting options are available?

Adroit SCADA Intelligence reporting and analysis is a separate product that leverages the Microsoft SQL BI platform. Users configure the data sources and other context and attributes and the solution automatically processes the data into the warehouse and cube. This allows for easy analysis and report generation using any tools that are OLAP aware, these include Excel and MS Reporting Services.

Maintenance, reliability and asset optimisation

Q: What maintenance, reliability, asset optimisation and/or continuous improvement related modules or capabilities does the product incorporate?

ISA 101 supported Situational Awareness wizards and controls are being launched with Adroit 8.4 (not yet officially released). In addition the Alarm Management and Analysis reporting tools allow customers to understand problematic alarms and this supports a continuous improvement programme.

PLC configuration and programming

Q: What capabilities does the scada offer in terms of generation and/or management of PLC configuration files or PLC application code?

MAPS (Mitsubishi Adroit Process Suite) is based on Adroit SCADA architecture. It is capable of generating PLC code to the Q and L Series Mitsubishi PLCs. MAPS is an integrated solution that incorp-orates all the standard flexibility and functionality of the standard Adroit SCADA product.

Security and data protection

Q: What authentication, authorisation and role management models are available for the runtime environment?

The entire Adroit SCADA platform is built on the Windows security platform and model.

Unique selling proposition (USP)

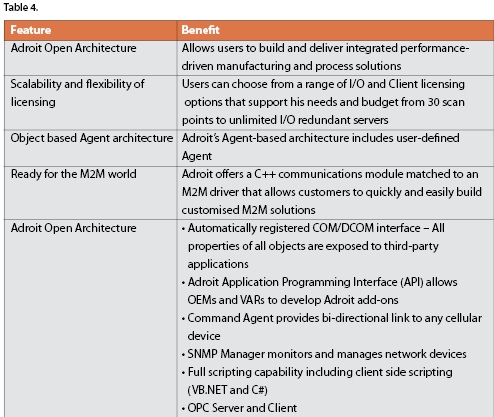

Q: List the top five feature/benefit pairs that contribute to this product’s USP.

To view the unabridged version of this scada review, visit http://instrumentation.co.za/+C20136

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved