Historical perspective

There is some dispute over who perfected the laser as a working technology, with some believing the accolade should go to Gordon Gould. Other names associated with pioneering work on laser principles include Charles Townes, Alexander Prokhorov and Arthur Schawlow. However, it is widely acknowledged that Theodore Maiman’s Ruby Laser, in 1960, was the first functional prototype. From then, various laser types have emerged such as helium neon and carbon dioxide gas lasers. Now, more than 50 years on, and in the same spirit of innovation, ABB is forging ahead with its latest laser level measurement technology.

Today, ABB’s laser products are managing bulk solids and opaque liquid level applications across the mining, power, food and beverage, pulp and paper and chemicals industries. Typical applications include level sensing and control in bins or silos, positioning of conveyors/tripper cars, height control, level control in crushers or shredders, movement detection, anti-collision of overhead cranes, block chute detection and positioning of machinery. The products serve a broad range of companies in the mining, power generation, manufacturing and many other industries.

The laser (light amplification by stimulated emission of radiation) was a remarkable technical breakthrough, but in its early years it was something of a technology without a purpose. Almost immediately, though, engineers began to find uses for it. Among them were the military weapons laser rangefinder and land surveying. From these early developments the current laser level measurement technology emerged.

ABB, through its acquisition of K-TEK, has brought this remarkably economical technology to the industrial market. The ABB laser level product range was initially designed and developed in the early 1980s by a South African company, Coherent Laser Systems, which later changed its name to Laser Measurement, or LaserM for short.

LaserM was the recipient of numerous SABS design and prototype awards, was listed as a Technology Top 100 company several times and won the President’s SME export award in 2001.

The potential of LaserM’s technology was soon recognised by USA-based K-TEK and the company was acquired in 1999. ABB, through its acquisition of K-TEK, is now bringing the technology to its extensive portfolio of industrial customers.

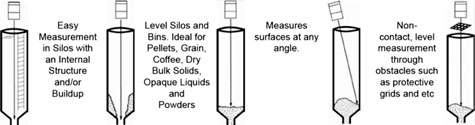

Laser level measurement technology in industry

Laser technology in level/positioning measurement brings a number of unique advantages to the table. Firstly, its short wavelength results in a narrow beam (approximately 5 cm diameter) with extremely low divergence (<0,5°). This enables the instrument to measure accurately into silo cones or chutes, to see through narrow openings in protective grids, and to be completely unaffected by obstacles close to or moving in its area of operation. It is also unaffected by electrical noise, wind or temperature fluctuations. Also, ABB’s laser instruments measure distance off any surface, from black coal to brown wood chips to reflective plastics, at any angle, and with no false echoes.

ABB’s general application product, the LM80, easily measures distances up to 18 m on coal and up to 150 m on positioning applications using a reflector plate. The ‘big brother’ product, the LM200, has enhanced optics and reads at least 30 m on coal and up to 400 m on positioning applications using a reflector plate. The instruments give a reading in centimetres through a 4-20 mA output and are accurate within 25 mm across the measuring range. All lasers are rated as Class 3R and are completely safe.

Nadia Nilsen, local business unit manager for ABB Measurement Products says of the laser product range: “It is a plug-and-play instrument, or rather point-and-shoot and its user friendly menu makes for a quick setup on commissioning through a handheld programmer or laptop. It requires no calibration or special configuration. The laser pointer provides precise alignment and a number of mounting options are available. The laser products provide accurate, fast, reliable level and positioning measurement.

“The downside from our perspective, is that they just keep on working. We have some in the field that are more than 15 years old and still going strong. This prevents us from selling replacement units. We are delighted by the reliability.”

For more information contact ABB South Africa, +27 (0)10 202 5000, [email protected], www.abb.com/za

| Tel: | +27 10 202 5000 |

| Email: | [email protected] |

| www: | www.abb.com/za |

| Articles: | More information and articles about ABB South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved