The flexible and advanced production systems at Austrian automobile manufacturer, Magna Steyr, are characterised by robots in assembly cells working practically hand in hand with their human counterparts. Safety at work is a top priority, so equipment manufacturer EBZ created an advanced safety concept based on PROFIsafe, with safety sensors from Leuze.

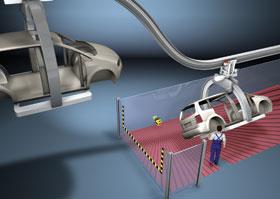

Flexible production lines allow Magna Steyr to manufacture several different types of vehicles in one line. This requires not only personnel, but also robots and tools to be highly adaptable. The combination of manual activities with automated processes creates a spatially close working area for humans and machines, which demands very sophisticated safety interlocking.

A typical area in which robots work with their human counterparts is during the manufacture of vehicle bodies, or more specifically, the construction of the Peugeot RCS sport coupé, which is the first entire vehicle that Peugeot Citroën has assigned to Magna Steyr.

In total, there are 23 industrial robots linked to one another in this production section, handling vehicle body parts and welding tools in a dynamic fashion. There are also 16 insertion points where employees enter the robot working areas to place new components into the system. At each of these points, people or objects must be prevented from entering the area while the robots are working.

“Both these safety requirements are fulfilled by a combination of Leuze Compactplus safety light curtains and Leuze Rotoscan RS4 safety laser scanners,” explains Gerry Bryant, managing director of Countapulse Controls. “While the light curtains protect the vertical access area by disabling the respective system when crossed, the scanners guard the so-called stepping-behind area. These are area scanners and this particular type 3 electro-sensitive protective equipment detects bodies, legs, arms or hands in protected field contours, which can be configured in any dimension.”

PROFIsafe in connection

Both systems feature an integrated Profibus DP connector unit. The functional extension of PROFIsafe enables the entire operation of non-safe standard automation devices and safety devices on Profibus.

“Separate terminal boxes for the Leuze safety sensors are not needed, as they are directly connected to the bus,” Bryant says. “The PROFIsafe sensors do not require any modifications to existing hardware components and can be integrated easily into existing systems. The PROFIsafe communication standard presents a considerable potential for savings, thanks to the wiring and the diversity of parts. It also offers the advantage of retrofit ability, which helps create the flexibility demanded at Magna Steyr.”

For more information contact Gerry Bryant, Countapulse Controls, +27 (0)11 615 7556, [email protected], www.countapulse.co.za

| Tel: | +27 11 548 9960 |

| Email: | [email protected] |

| www: | www.profiafrica.co.za |

| Articles: | More information and articles about PI SA (PROFIBUS & PROFINET SA) |

| Tel: | +27 11 615 7556/7/8 |

| Email: | [email protected] |

| www: | www.countapulse.co.za |

| Articles: | More information and articles about Countapulse Controls |

© Technews Publishing (Pty) Ltd | All Rights Reserved